Method for locally plating cadmium and gold on socket sintering assembly

A technology of local plating and components, applied in the direction of electrolytic components, cells, electrolysis process, etc., can solve the problems of difficulty in binding, influence of air tightness and insulation performance of socket sintered components, and difficulty in clamping, and achieves good electrical contact plugging performance. and welding performance, the thickness of the coating can be accurately controlled, and the effect of saving precious metals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

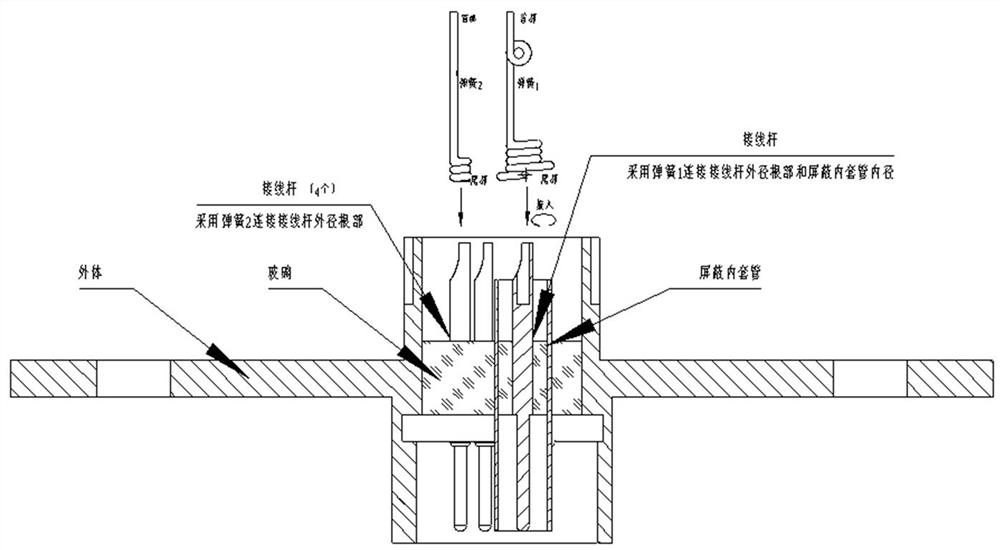

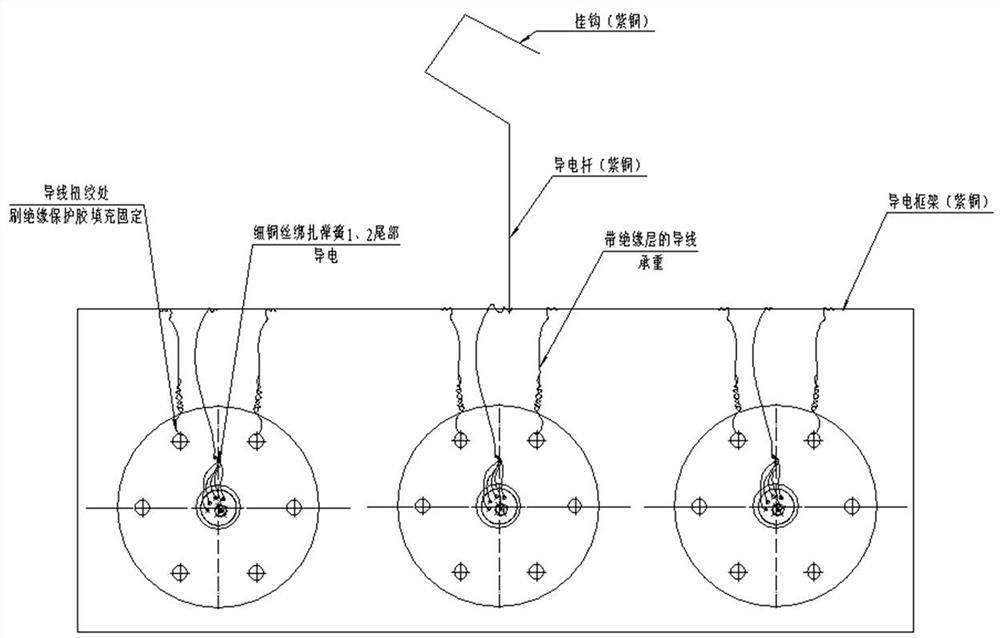

[0036] This embodiment provides a method for local cadmium plating and gold plating of socket sintered components, specifically: in a washing cabinet with ventilation, put the socket sintered components into a stainless steel basin and pour RH-70 aviation kerosene to clean and degrease with a brush , and dry naturally at room temperature; then put the parts into a plastic basket into a 50% volume ratio of hydrochloric acid solution for pickling, corrode for 3 minutes at room temperature, and wash with running water for 1 minute, and then dry the parts with compressed air. Coating protective glue: add a small amount of red dye to Q98-1, and stir evenly, and add an appropriate amount of X-1 thinner to adjust the viscosity of the glue to facilitate plating. Use a pencil and a willow stick dipped in Q98-1 protective glue to evenly coat the glass surface, dry it naturally for 30 minutes, apply the second coat, and dry it naturally for 4 hours. Hanging: Use red copper wire to pass t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com