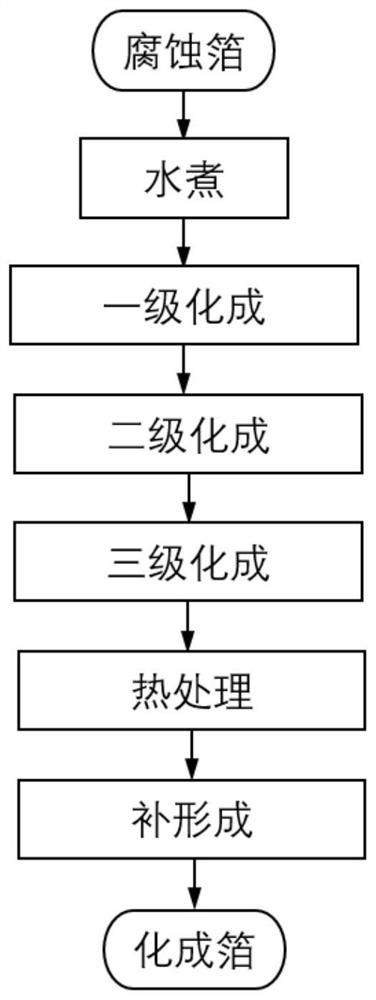

Multi-stage high-specific-volume high-pressure aluminum foil formation method

A technology of high-voltage aluminum foil and formation method, which is applied in the manufacture of capacitors, electrolytic capacitors, and electrolytic capacitors. It can solve the problems of many formation steps, high boric acid content, and low conductivity, so as to reduce side reactions, improve CV performance, and product performance. Enhanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

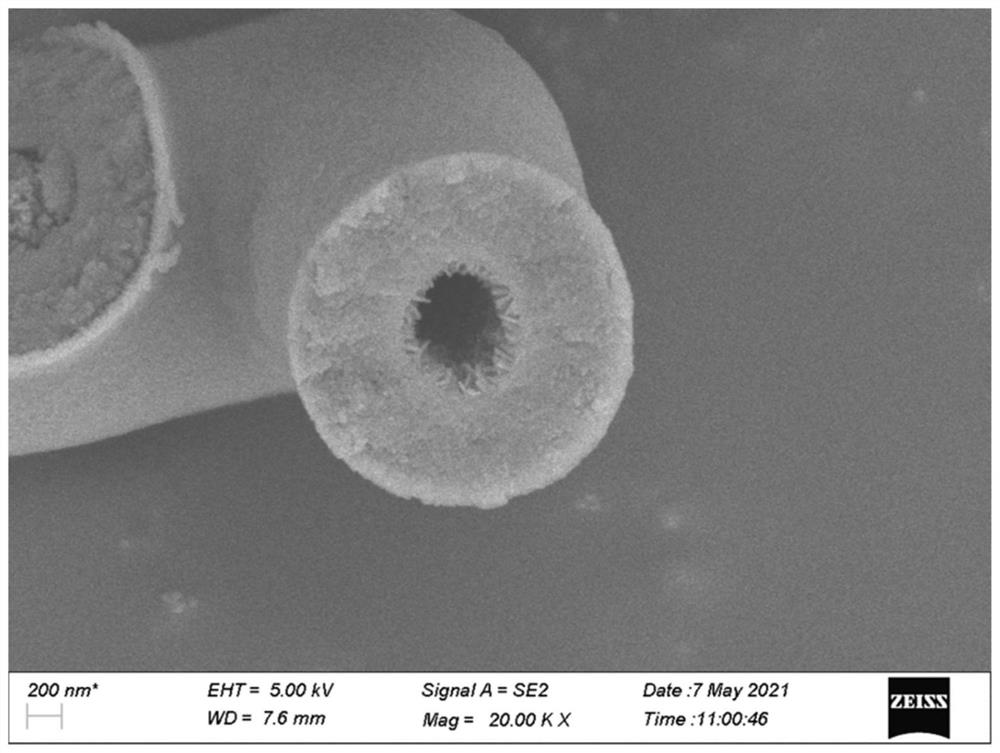

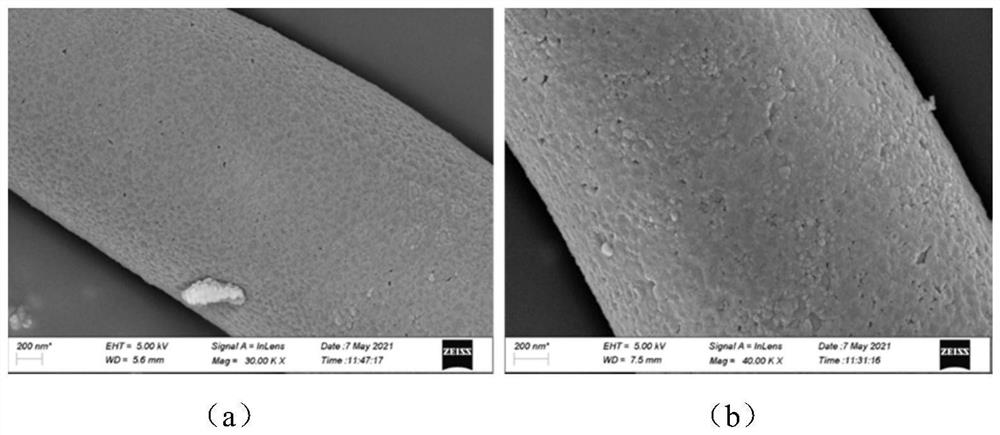

Image

Examples

Embodiment 1

[0068] First, prepare the primary chemical forming liquid, secondary chemical forming liquid, tertiary chemical forming liquid and replenishing liquid according to the following process:

[0069] 1) Primary chemical conversion solution: add the main solute and auxiliary solute into deionized water, mix evenly, adjust the pH to 5 with ammonia water, and obtain the primary chemical conversion solution. The main solute is a mixture of ammonium adipate and ammonium suberate, the mass fraction of ammonium oxalate in the primary chemical solution is 5%, the mass fraction of ammonium suberate is 5%; the auxiliary solute is the mixture of citric acid and tartaric acid For the mixture, the mass fraction of citric acid in the primary conversion solution is 3%, and the mass fraction of tartaric acid is 2%.

[0070] 2) Secondary chemical formation solution: adding the main solute and auxiliary solute into deionized water, mixing evenly, and adjusting the pH to 5 with ammonia water to obta...

Embodiment 2

[0088] First, prepare the primary chemical forming liquid, secondary chemical forming liquid, tertiary chemical forming liquid and replenishing liquid according to the following process:

[0089] 1) Primary chemical conversion solution: add the main solute and auxiliary solute into deionized water, mix evenly, adjust the pH to 5 with ammonia water, and obtain the primary chemical conversion solution. The main solute is a mixture of ammonium adipate and ammonium suberate, the mass fraction of ammonium oxalate in the primary chemical solution is 4%, the mass fraction of ammonium suberate is 4%; the auxiliary solute is the mixture of citric acid and tartaric acid For the mixture, the mass fraction of citric acid in the primary conversion solution is 2%, and the mass fraction of tartaric acid is 2%.

[0090] 2) Secondary chemical formation solution: adding the main solute and auxiliary solute into deionized water, mixing evenly, and adjusting the pH to 5 with ammonia water to obta...

Embodiment 3

[0108] First, prepare the primary chemical forming liquid, secondary chemical forming liquid, tertiary chemical forming liquid and replenishing liquid according to the following process:

[0109] 1) Primary chemical conversion solution: add the main solute and auxiliary solute into deionized water, mix evenly, adjust the pH to 5 with ammonia water, and obtain the primary chemical conversion solution. The main solute is a mixture of ammonium adipate and ammonium azelate, the mass fraction of ammonium oxalate and ammonium azelate in the primary chemical solution is 3%; the auxiliary solute is citric acid and homophenylene For the mixture of triformic acid, the mass fraction of citric acid in the primary conversion solution is 1.5%, and the mass fraction of trimesic acid is 1.5%.

[0110] 2) Secondary chemical formation solution: adding the main solute and auxiliary solute into deionized water, mixing evenly, and adjusting the pH to 5 with ammonia water to obtain the secondary ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com