Method for large-scale synthesis of tetrodotoxin

A tetrodotoxin and compound technology, applied in the field of artificial synthesis of tetrodotoxin, can solve problems such as lack of credibility, lack of value for large-scale synthesis and preparation of tetrodotoxin, and inability to produce tetrodotoxin on a large scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

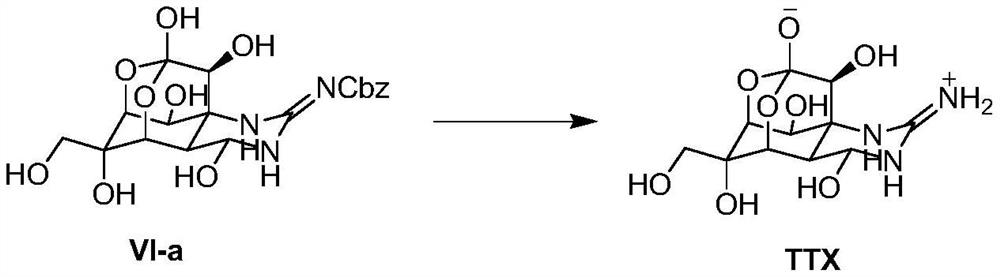

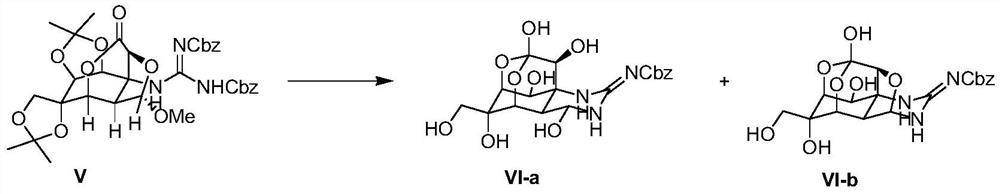

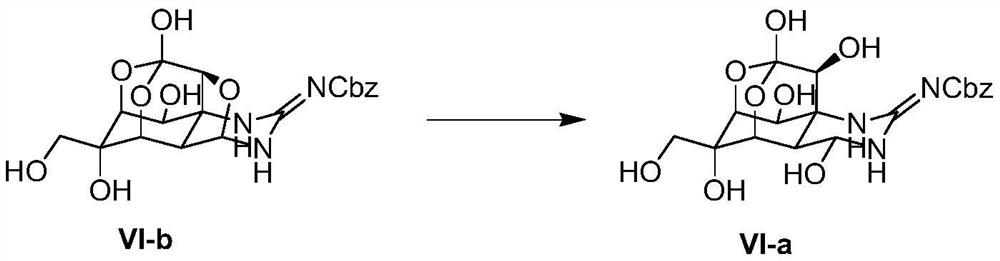

[0080] The technical problem to be solved by the present invention is to provide a method for artificially large-scale synthesis of tetrodotoxin that does not rely on natural sources such as puffer fish, that is, a chemical method for gram-scale synthesis of tetrodotoxin. Compared with the method reported in the prior art, the advantage of the chemical synthesis method of the present invention is that the improvement of the synthesis method and the purification method enables the present invention to have the ability to produce tetrodotoxin and its derivatives on a large scale according to the c-GMP standard above the gram level, It is possible to carry out clinical trials of tetrodotoxin as a candidate drug that meets regulatory specifications, and it has laid a solid API foundation for tetrodotoxin to become an important member of the field of human analgesia and detoxification drugs, including:

[0081] (1) Only one step of intramolecular transesterification reaction is need...

Embodiment 1

[0095] Example 1 : the preparation of formula III compound

[0096]

[0097] At room temperature, 12 g of compound II and 6 g of potassium carbonate were dispersed in 300 ml of methanol, stirred at room temperature for 18 hours, HPLC detected that the raw materials disappeared, and the precipitate was removed by filtration, and most of the methanol was removed by rotary evaporation of the filtrate at room temperature. Then add 300 ml of water, extract the reaction solution three times with 300 ml of ethyl acetate, combine the organic phases, dry over anhydrous sodium sulfate, filter and spin dry, and use ethyl acetate-petroleum ether (1:3) silica gel column chromatography to obtain white Foamy solid compound III (7.3 g, yield 75%). 1H NMR (CDCl 3 ,400MHz):δ5.16(s,1H),5.02(d,J=6.9Hz,1H),5.01(s,1H),4.42(s,1H),4.41(d,J=6.9Hz,1H) ,4.37(d,J=10.1Hz,1H),4.32(s,1H),4.25(d,J=10.1Hz,1H),3.48(br s,1H),3.44(s,3H),1.46(s ,9H), 1.43(s,3H), 1.38(s,3H), 1.29(s,3H).

Embodiment 2

[0098] Example 2 : the preparation of formula IV compound

[0099]

[0100] Under ice bath, add 180 ml of freshly prepared TMSI solution (0.32M) to 6.9 g of compound III in 240 ml of anhydrous acetonitrile solution, react at room temperature for 15 minutes, add 450 ml of sodium thiosulfate solution to quench the reaction, and use chloroform- Methanol (9:1) was extracted three times with 450 ml of mixed solvent, the combined organic phases were dried over anhydrous sodium sulfate, filtered and concentrated to obtain crude compound IV (5.4 g), which was directly put into the next reaction without purification. 1 H NMR (CDCl 3 ,400MHz):δ6.34(br,2H),5.32(d,J=7.2Hz,1H),5.30(s,1H),4.79(d,J=1.2Hz,1H),4.42(d,J= 7.6Hz, 1H), 4.39(s, 1H), 4.38(d, J=10.0Hz, 1H), 4.28(d, J=10.4Hz, 1H), 3.57(s, 3H), 3.36(t, J= 2.0Hz, 1H), 2.03(d, J=8.0Hz, 1H), 1.46(s, 3H), 1.44(s, 6H), 1.38(s, 3H), 1.36(s, 3H).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com