Anti-precipitation and low-haze starch-based fully biodegradable PBAT alloy and preparation method thereof

A low-haze, starch-based technology, applied in the field of starch-based fully biodegradable PBAT alloy and its preparation, can solve the problems of shortened shelf life, reduced product performance, product stickiness, etc. The effect of linking degree and avoiding degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

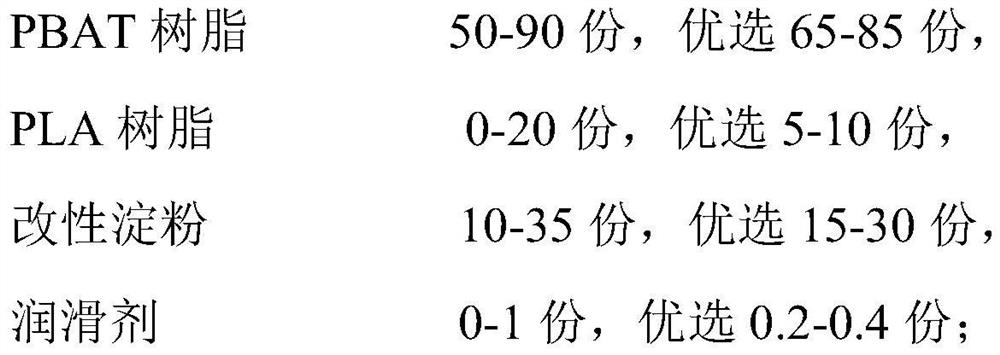

Method used

Image

Examples

Embodiment 1

[0058] (1) Preparation of modified starch (M-starch A):

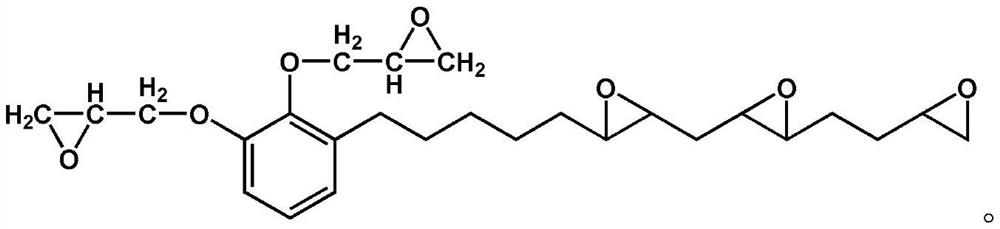

[0059] The first step is to accurately weigh 60g urushiol, 1.5g trioctylmethyl ammonium chloride and 40g epichlorohydrin in a three-necked flask, install them, stir at 75°C for 4h, cool to 55°C, and add 20ml dropwise Sodium hydroxide solution (C=7.5mol / L), stirred for 4h, cooled to room temperature. Wash with deionized water until neutral, separate the organic phase with a pear-shaped separatory funnel, and finally decompress and rotary evaporate the water and epichlorohydrin in the organic phase to obtain urushiol glycidyl ether;

[0060] In the second step, add 60g of urushiol glycidyl ether into a three-necked flask, dropwise add 100ml of chloroform solution containing 40g of m-chloroperoxybenzoic acid, stir at 35°C for 4h, wash with saturated sodium hydroxide solution until neutral, and pass through a separatory funnel Isolate and obtain epoxidized urushiol glycidyl ether;

[0061] 1600cm in infrared analysis -1 ...

Embodiment 2

[0070] (1) Preparation of modified starch (M-starch B):

[0071] The first step is to accurately weigh 80g of urushiol, 3g of tetrabutylammonium chloride and 20g of epichlorohydrin in a three-necked flask, install them, stir at 85°C for 2h, cool to 65°C, and drop 20ml of hydroxide Sodium solution (C=7.5mol / L), stirred for 2h, cooled to room temperature. Wash with deionized water until neutral, separate the organic phase with a pear-shaped separatory funnel, and finally decompress and rotary evaporate the water and epichlorohydrin in the organic phase to obtain urushiol glycidyl ether;

[0072] In the second step, add 80g of urushiol glycidyl ether into a three-necked flask, dropwise add 100ml of chloroform solution containing 20g of benzoic acid peroxide, stir at a constant temperature of 65°C for 2h, wash with saturated sodium hydroxide solution until neutral, and separate through a separatory funnel to obtain Epoxy urushiol glycidyl ether;

[0073] In the third step, weigh...

Embodiment 3

[0081] (1) Preparation of modified starch (M-starch C):

[0082] The first step is to accurately weigh 70g urushiol, 2g benzyltriethylammonium chloride and 30g epichlorohydrin in a three-necked flask, install them, stir at 80°C for 3h, cool to 60°C, and drop 20ml of Sodium hydroxide solution (C=7.5mol / L), stirred for 2h, cooled to room temperature. Wash with deionized water until neutral, separate the organic phase with a pear-shaped separatory funnel, and finally decompress and rotary evaporate the water and epichlorohydrin in the organic phase to obtain urushiol glycidyl ether;

[0083] In the second step, add 70g of urushiol glycidyl ether into a three-necked flask, dropwise add 100ml of chloroform solution containing 30g of benzoyl peroxide, stir at a constant temperature of 40°C for 3h, wash with saturated sodium hydroxide solution until neutral, and separate through a separatory funnel Obtain epoxy urushiol glycidyl ether;

[0084] In the third step, weigh 1.6 kg of co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Epoxy value | aaaaa | aaaaa |

| Epoxy value | aaaaa | aaaaa |

| Epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com