Amphiphilic compatilizer and preparation method thereof and polycarbonate-polypropylene alloy material

A polycarbonate and compatibilizer technology, used in the field of thermoplastic polymer materials, can solve the problems of product quality decline, poor heat resistance, poor processing fluidity, etc. The effect of improving the combustion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

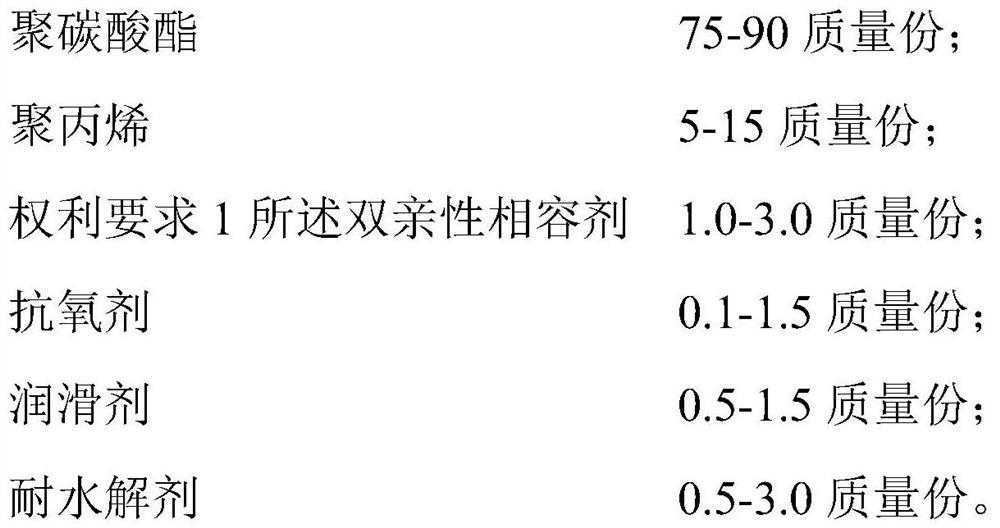

Embodiment 4

[0041] Polypropylene resin: prepared according to Example 4 of patent CN200410009906.6;

[0042]Composite antioxidant: a compound of hindered phenol and phosphite in a weight ratio of 1:1 (Rhein Chemical Co., Ltd.);

[0043] Lubricant: glyceryl monostearate (produced by Lonza Corporation of the United States);

[0044] Hydrolysis resistance agent: Stabilizer 9000DF (RASCHIG, Germany);

[0045] Acrylic graft polyethylene graft: PX3243 (Dongguan Suda Plastic Material Co., Ltd.);

[0046] Styrene-ethylene-butylene-styrene block copolymer (SEBS): H1221 (Asahi Kasei, Japan);

[0047] Hexafluorodianhydride (2,2'-bis(3,4-dicarboxylic acid) hexafluoropropane dianhydride): Yuanye Biotechnology Co., Ltd.;

[0048] Allyl alcohol: Hubei Xinrunde Chemical Co., Ltd.;

[0049] DOPO (9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide): Jusheng Technology Co., Ltd.

Embodiment 1

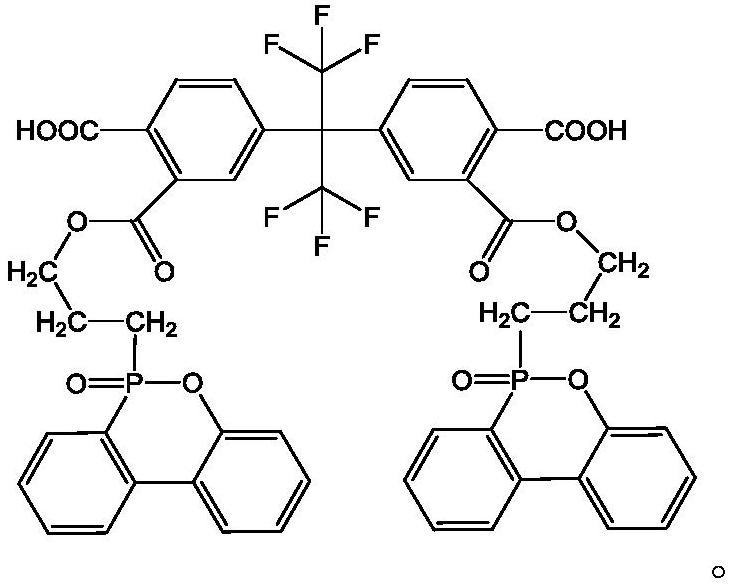

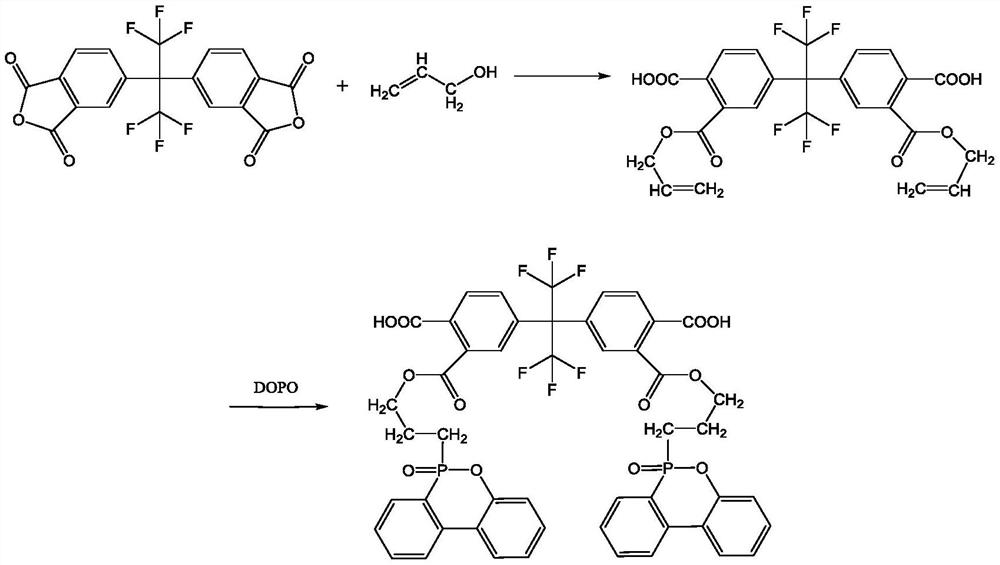

[0051] In a three-necked flask, a quantitative amount of hexafluorodianhydride (2,2'-bis(3,4-dicarboxylic acid) hexafluoropropane dianhydride) was dissolved in ethyl acetate solution, and allyl alcohol was added for esterification Reaction, heating and stirring to 80°C, reflux reaction for 6h; the product was recrystallized with DMAc / THF, rinsed with THF, and finally vacuum-dried to obtain product I, in which hexafluorodianhydride (2,2'-bis(3,4-di The molar ratio of carboxylic acid) hexafluoropropane dianhydride) to allyl alcohol is 1:1. NMR of product Ⅰ 1 In the H spectrum: the displacement of the H atom on the benzene ring is 7.72-7.98cm -1 In the interval; the displacement of the H atoms in the carboxyl groups at both ends of the molecule is 13.29cm -1 ;-CH 2 The displacement is 4.86cm -1 , = The displacement of CH- is 6.05cm -1 ,=CH 2 The displacements are 5.31cm -1 and 5.32cm -1 .

[0052]

Embodiment 2

[0054] Add quantitative DOPO (9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide) and product I into a round-bottomed flask, heat and stir to 80°C, and reflux for 6 hours; then the product Dissolved with acetone, then added 1000mL chloroform as a precipitant, filtered to obtain a solid product and then vacuum-dried to obtain a compatibilizer II, wherein DOPO (9,10-dihydro-9-oxa-10-phosphaphenanthrene-10 -oxide) and product I in a molar ratio of 1:1. NMR of product Ⅱ 1 In the H spectrum: the displacement of the H atom on the benzene ring is 7.36-8.00cm -1 In the interval; the displacement of the H atoms in the carboxyl groups at both ends of the molecule is 13.29cm -1 ;-CH 2 The displacement from near to far away from the ester group is 4.30cm -1 、2.29cm -1 、3.99cm -1 .

[0055]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com