Preparation method of soluble low-temperature rapid imidization polyimide film

A technology of imidization polyimide and polyimide film, which is applied in the field of preparation of soluble, low-temperature rapid imidization polyimide film, and can solve the problem of high imidization temperature and long time problem, achieve the effect of reducing activation energy, improving interaction and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

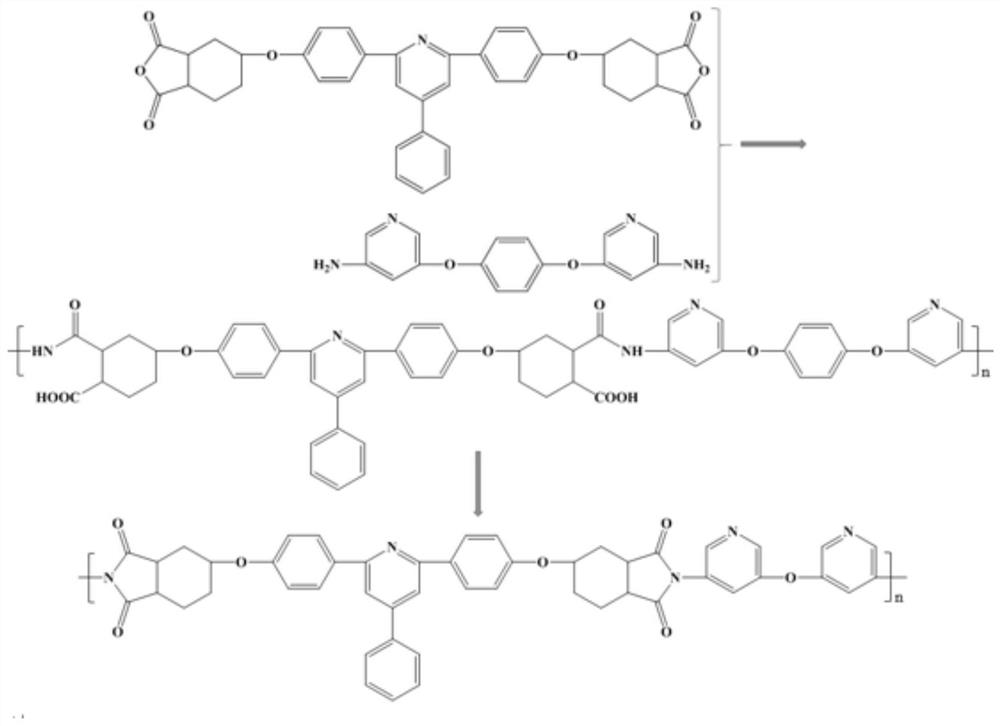

Embodiment 1

[0033] Add 120g of diglyme at room temperature into a 250mL three-necked flask equipped with mechanical stirring, add 4.4g (0.0150mol) of p-bis(5-amino-3-pyridyloxy)benzene, stir to dissolve it, and pass N 2 , add 10g (0.0156mol) 4-phenyl-2,6-bis[4-(3,4-dicarboxycyclohexane ether) phenyl]pyridine dianhydride in 3 times within 1h, and then continue at room temperature Stir for 20 hours to obtain a polyamic acid solution, vacuum degassing for 10 minutes, apply the solution to a 50 μm thick film on a dry and clean glass plate with a film applicator, and place it in a vacuum oven at 190 ° C to the maximum vacuum degree for 90 minutes. After reaching room temperature, peel off from the glass plate to obtain the polyimide film, which is soluble in diglyme at room temperature. The reaction circuit diagram of the polyimide film of the present embodiment is shown in figure 1 .

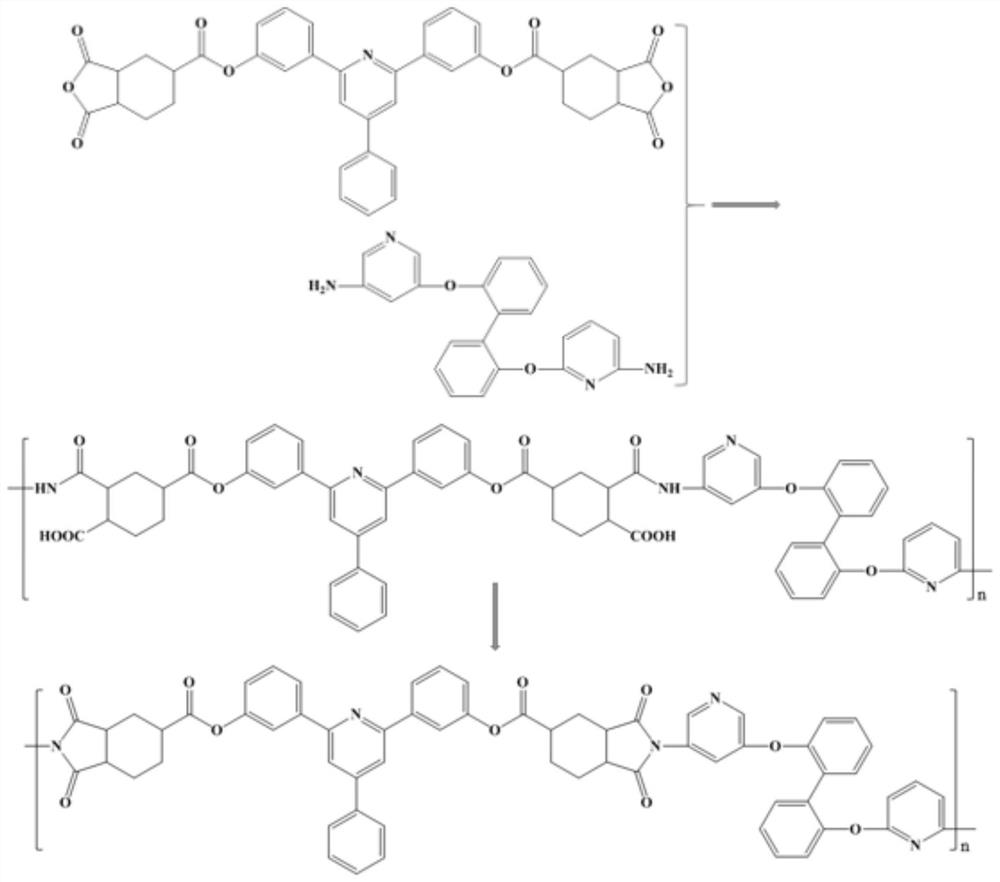

Embodiment 2

[0035] Add 120g of N,N-dimethylacetamide into a 250mL three-necked flask equipped with mechanical stirring at room temperature, add 5.6g (0.0151mol) of 2,2'-bis(5-amino-3-pyridyloxy)bis Benzene, stirred to dissolve, through N2 , add 11g (0.0157mol) 4-phenyl-2,6-bis[3-(3,4-dicarboxycyclohexyl ester) phenyl]pyridine dianhydride in 3 times within 1h, and then continue at room temperature Stir for 24 hours to obtain a polyamic acid solution, vacuum defoam for 10 minutes, use a film applicator to coat the obtained polyamic acid solution on a dry and clean glass plate into a film with a thickness of 40 μm, and place it in a vacuum box at 180°C to evacuate to the maximum vacuum temperature insulation for 80min, after being down to room temperature, peel off from the glass plate to obtain a polyimide film, which can be dissolved in N,N-dimethylacetamide at room temperature, the reaction circuit of the polyimide film of the present embodiment picture see figure 2 .

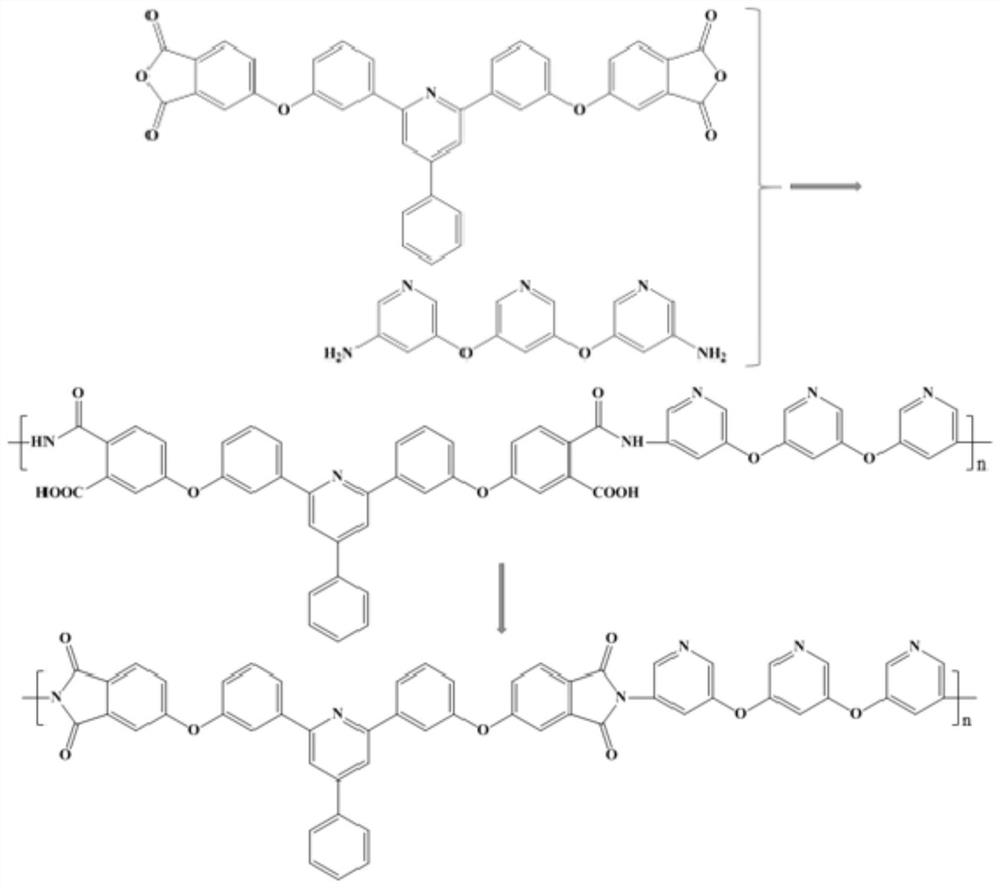

Embodiment 3

[0037] Add 140g of N,N-dimethylacetamide to a 250mL three-necked flask equipped with mechanical stirring at room temperature, add 6.75g (0.0230mol) of 3,5-bis(3-amino-5-pyridyloxy)pyridine, Stir to dissolve, pass N 2 , add 15.31g (0.0243mol) 4-phenyl-2,6-bis[3-(3,4-dicarboxyphenyl ether) phenyl]pyridine dianhydride in 3 times within 1h, then continue to stir at room temperature The polyamic acid solution was obtained in 18 hours, vacuum degassed for 10 minutes, and the obtained polyamic acid solution was coated on a dry and clean glass plate to form a 40 μm thick film with a film applicator, and placed in a vacuum oven at 175 ° C to the maximum vacuum degree Insulated for 60min, after being lowered to room temperature, peel off from the glass plate to obtain a polyimide film, which can be dissolved in N,N-dimethylacetamide at room temperature, the reaction circuit diagram of the polyimide film of this embodiment See image 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com