Preparation method of gel microorganism composite microspheres combining chemical repairing agent and microorganisms

A technology of composite microspheres and chemical remediation, applied in the direction of microorganism-based methods, chemical instruments and methods, biochemical equipment and methods, etc., can solve problems such as soil heavy metal pollution, achieve easy implementation, reduce heavy metal content, and passivation ability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

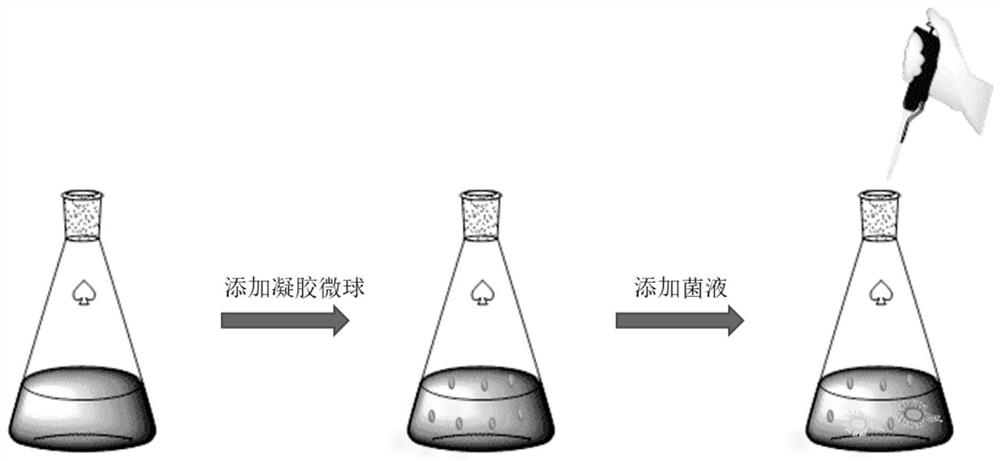

[0026] The present invention provides a kind of preparation method of the gel microorganism composite microsphere that chemical restoration agent and microorganism combine, comprise the following steps:

[0027] S1. The inorganic filler and the gel monomer are polymerized into gel microspheres under the initiation of the initiator ammonium persulfate;

[0028] S2, the gel microspheres are dispersed in water after centrifugal purification, adjusted to PH to 12 with NaOH, freeze-dried to become gel microsphere powder;

[0029] S3. The gel microsphere powder is dissolved in the microbial liquid. Through the superabsorption of sodium carboxylate, a large amount of microbial liquid is absorbed to prepare a gel microbiological composite microsphere, and the chemical repair agent is realized through the gel microsphere and the microorganism. combination with microorganisms.

[0030] Preferably, the inorganic filler is at least one of diatomaceous earth, limestone and activated carbo...

Embodiment 1

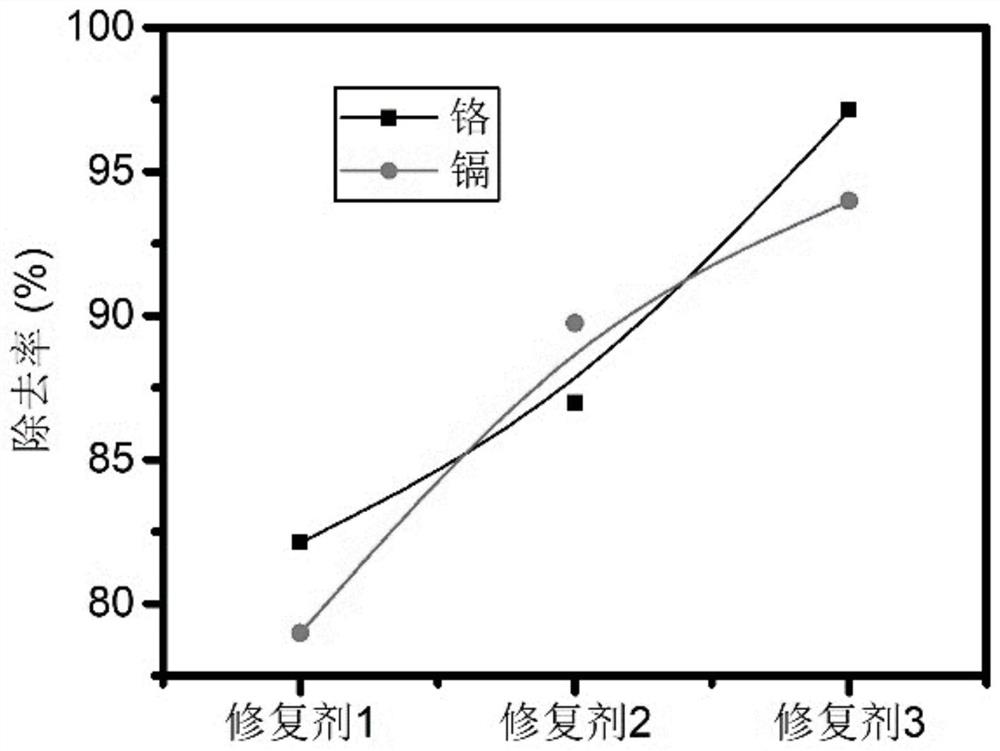

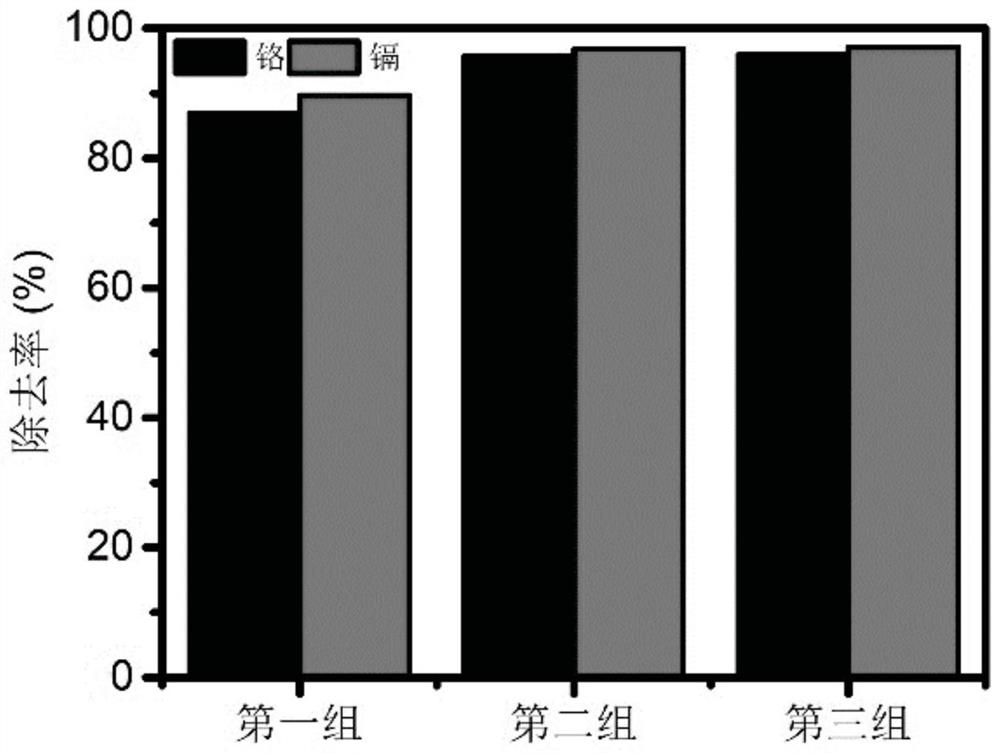

[0037] First, the inorganic filler diatomite is ground through an 80-mesh sieve to obtain uniform diatomite particles. Diatomaceous earth was dissolved in 100m of water, and 2g of acrylic acid, 3g of N-methylolacrylamide, and 1g of styrene were added. Pass through N2 protection, add potassium persulfate initiator at 300r / min and 70°C, and polymerize for 8 hours to obtain gel microsphere polymerization solution. After centrifugal purification, adjust the pH to 12 with NaOH, centrifuge, and dry to obtain gel microspheres. Add 10 g of tryptone, 5 g of yeast extract, and 10 g of NaCl to 950 ml of deionized water, adjust the pH of the medium to 7.4 with NaOH, and then dilute to 1 L with deionized water. The above-mentioned LB medium was used for the cultivation of D10 rhizobia and W33 rhizobia as microorganisms, and a composite bacterial suspension was prepared after shaking at 150 rpm for 24 hours at 28°C. The gel microspheres and the composite bacterial suspension were mixed ac...

Embodiment 2

[0044] First, the inorganic filler diatomite is ground through an 80-mesh sieve to obtain uniform diatomite particles. Dissolve diatomaceous earth and limestone in 100m of water, add 2g of acrylic acid, 3g of N-methylolacrylamide, and 10g of methacrylate. Pass through N2 protection, add potassium persulfate initiator at 300r / min and 70°C, and polymerize for 8 hours to obtain gel microsphere polymerization solution. After centrifugal purification, adjust the pH to 12 with NaOH, centrifuge, and dry to obtain gel microspheres. Add 10 g of tryptone, 5 g of yeast extract, and 10 g of NaCl to 950 ml of deionized water, adjust the pH of the medium to 7.4 with NaOH, and then dilute to 1 L with deionized water. The above-mentioned LB medium was used for the cultivation of D10 rhizobia and W33 rhizobia as microorganisms, and a composite bacterial suspension was prepared after shaking at 150 rpm for 24 hours at 28°C. The gel microspheres and the composite bacterial suspension were mixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com