Sulfur-modified iron-cobalt oxide nanosheet Fenton-like catalyst as well as preparation method and use method thereof

A technology of oxides and nanosheets, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of complex operation, low removal rate, high catalyst cost, etc., achieve efficient degradation and improve catalytic performance The effect of activity and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

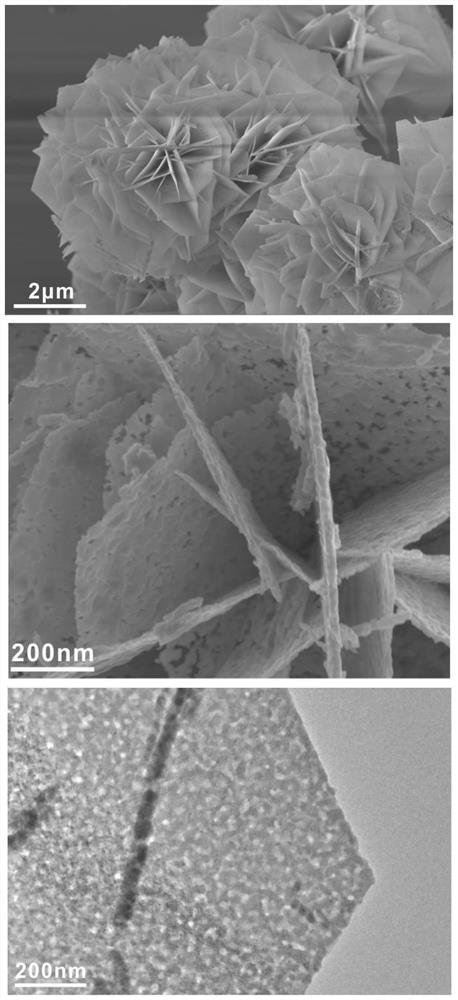

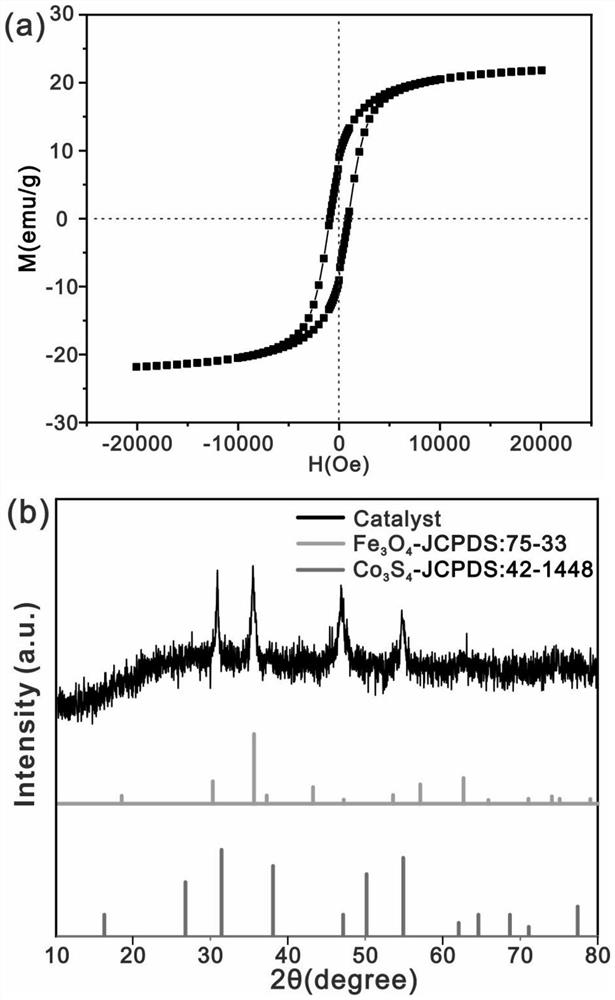

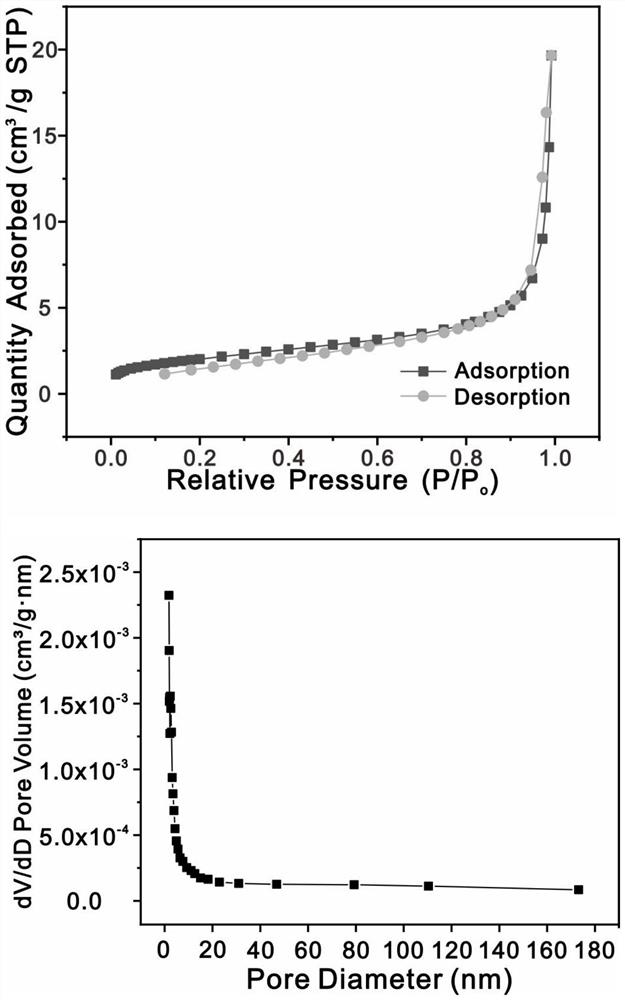

[0031] The invention provides a method for preparing a sulfur-modified iron-cobalt oxide nanosheet Fenton catalyst, comprising the following steps:

[0032] 1) After mixing cobalt nitrate hexahydrate solution, ferrous sulfate heptahydrate solution, ammonium fluoride and urea, hydrothermal reaction is carried out to obtain solid precipitation;

[0033] 2) vacuum-drying and calcining the solid precipitate in sequence to obtain a precursor;

[0034] 3) Calcining the precursor and sublimed sulfur under an inert atmosphere to obtain a sulfur-modified iron-cobalt oxide nanosheet-like Fenton catalyst.

[0035] Step 1) of the present invention, the volume ratio of the cobalt nitrate hexahydrate solution and the ferrous sulfate heptahydrate solution is preferably 1~2:1~2, more preferably 1:1; the concentration of the cobalt nitrate hexahydrate solution is preferably 0.03~ 0.04mol / L, more preferably 0.032~0.037mol / L, more preferably 0.033~0.034mol / L; the concentration of ferrous sulfat...

Embodiment 1

[0062] Cobalt nitrate hexahydrate solution and ferrous sulfate heptahydrate solution were prepared in 15 mL deionized water respectively, the concentrations of cobalt nitrate solution hexahydrate solution and ferrous sulfate heptahydrate solution were 0.034mol / L and 0.017mol / L respectively. Mix cobalt nitrate hexahydrate solution and ferrous sulfate heptahydrate solution, then add ammonium fluoride and urea, the molar ratio of ferrous sulfate heptahydrate, ammonium fluoride and urea is 1:10:15, stir and mix for 1 hour to obtain a uniform solution .

[0063] The homogeneous solution was transferred to a 50mL polytetrafluoroethylene-lined reactor, the temperature was raised to 120°C at a rate of 4°C / min, and the hydrothermal reaction was carried out at 120°C for 9 hours and then cooled naturally. The obtained precipitate was washed alternately with deionized water and 98% ethanol for a total of 4 times, and collected by centrifugation to obtain a solid precipitate. Dry the soli...

Embodiment 2

[0072] Cobalt nitrate hexahydrate solution and ferrous sulfate heptahydrate solution were prepared in 15mL deionized water respectively, the concentrations of cobalt nitrate solution hexahydrate solution and ferrous sulfate heptahydrate solution were 0.032mol / L and 0.017mol / L respectively. Mix cobalt nitrate hexahydrate solution and ferrous sulfate heptahydrate solution, then add ammonium fluoride and urea, the molar ratio of ferrous sulfate heptahydrate, ammonium fluoride and urea is 1:9.6:14.6, stir and mix for 1 hour to obtain a uniform solution .

[0073] The homogeneous solution was transferred to a 50 mL polytetrafluoroethylene-lined reaction kettle, and the temperature was raised to 110 °C at a rate of 3 °C / min, and the hydrothermal reaction was carried out at 110 °C for 10 h, and then cooled naturally. The obtained precipitate was alternately washed with deionized water and 97% ethanol for a total of 5 times, and collected by centrifugation to obtain a solid precipitat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com