Acrylic acid-sodium acrylate-sulfonic acid inner salt copolymerization cross-linked product and preparation method and application thereof

A sulfonic acid inner salt, copolymerization and cross-linking technology, applied in the field of hydrogel, can solve the problems of low fresh water absorption rate, limited commercial competitiveness, and difficult expansion of the inner salt ring, etc., to achieve low fresh water absorption rate, low cost, Simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] This embodiment provides a copolymerized cross-linked product of acrylic acid-sodium acrylate-sulfonic acid inner salt, its structural formula is as follows:

[0031]

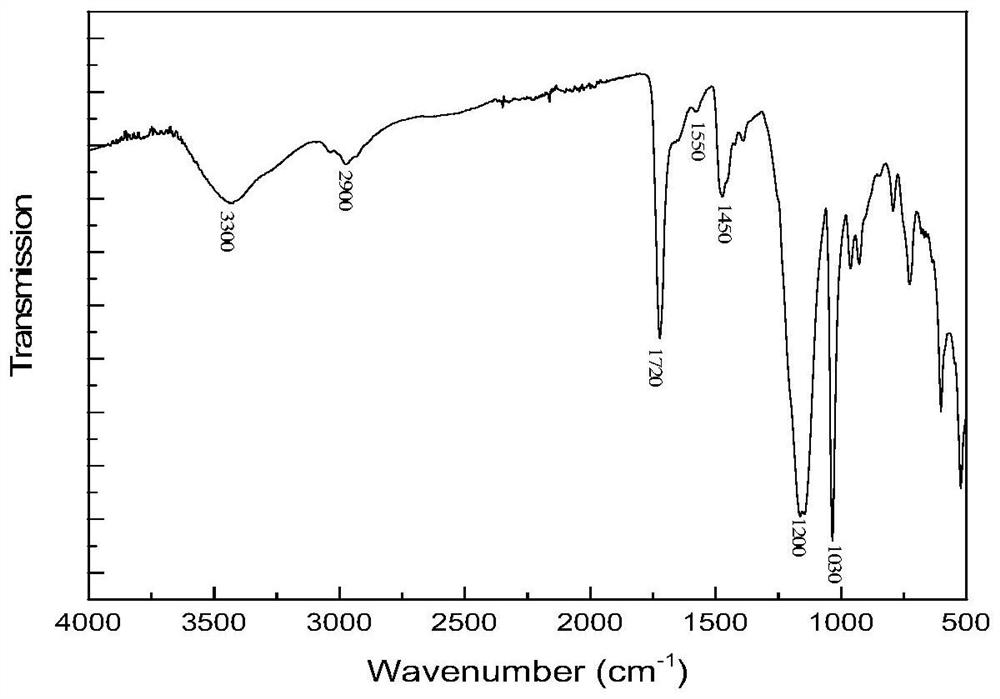

[0032] Use the FT-IR / FIR type infrared spectrometer of PerkinElmer company (USA) to carry out FTIR analysis to various functional groups in the product molecule, the result is as follows figure 1 shown;

[0033] For the infrared spectrum ( figure 1 ) analysis, it can be seen that:

[0034] 1720cm -1 Nearby are the C=O vibration peaks of -COOH and -COOR;

[0035] 1550cm -1 Yes - COO - of - O-C=O vibration characteristic peak;

[0036] 1030cm -1 Nearby is the C-N vibration peak;

[0037] 1200cm -1 -SO which is an aliphatic sulfonate 3 - The antisymmetric stretching vibration peak of

[0038] 3300cm -1 is the -OH stretching vibration peak;

[0039] 1450cm -1 is the methyl stretching vibration peak;

[0040] 2900cm -1 Nearby is the methylene stretching vibration peak.

Embodiment 2

[0042] This embodiment provides a method for preparing a copolymerized cross-linked product of acrylic acid-sodium acrylate-sulfonic acid inner salt, the preparation method comprising the following steps:

[0043] (1) Put 10g of acrylic acid, 4g of sodium hydroxide, and 10g of sultone into a dry reactor, dissolve them in 100g of distilled water, stir well, then add 0.005g of cross-linking agent, 0.2g of cerium ammonium nitrate, persulfuric acid Sodium 0.4g, sodium bisulfite 0.2g, sealed with nitrogen gas and evacuated, and reacted at a constant temperature of 40°C for 12 hours to obtain a crude product;

[0044] (2) Soak the obtained crude product in 500 mL of acetone for 24 hours, filter it with suction, dry it at 50°C, and crush it through a 100-mesh sieve to obtain a purified product, namely, the copolymerized cross-linked product of acrylic acid-sodium acrylate-sulfonic acid inner salt, and calculate the yield by weighing The rate is 96.8%.

Embodiment 3

[0046] This embodiment provides a method for preparing a copolymerized cross-linked product of acrylic acid-sodium acrylate-sulfonic acid inner salt, the preparation method comprising the following steps:

[0047](1) Put 10g of acrylic acid, 2g of sodium hydroxide, and 5g of sultone into the reactor, dissolve with 80g of distilled water, stir well, then add 0.1g of crosslinking agent, 0.1g of cerium ammonium nitrate, and 0.3g of sodium persulfate 1. 0.1 g of sodium bisulfite, sealed with nitrogen gas and evacuated, and reacted at a constant temperature of 80 ° C for 3 hours to obtain a crude product;

[0048] (2) Soak the obtained crude product in 500 mL of acetone for 24 hours, filter it with suction, dry it at 50°C, and crush it through a 100-mesh sieve to obtain a purified product, namely, the copolymerized cross-linked product of acrylic acid-sodium acrylate-sulfonic acid inner salt, and calculate the yield by weighing The rate is 98.9%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com