MPP pipe for electric power engineering and production process of MPP pipe

A technology for electric power engineering and pipes, which is applied in the field of MPP pipes for electric power engineering and its production process, which can solve the problems of poor weather resistance and easy aging, and achieve the effects of widening the applicable field, not being easy to break, and preventing expansion and extension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Preparation of reactive weathering agent:

[0053] Mix 0.1mol 2-(2'-hydroxy-5-methylphenyl)benzotriazole, 20mL methylhydroquinone, 0.1mol triethylamine and 80mL tetrahydrofuran, and stir at 55°C to make 2-(2 '-Hydroxy-5-methylphenyl) benzotriazole is completely dissolved, then add dropwise 50mL THF solution dissolved with 0.1mol methyl malonate chloride, the dropping rate is 3 drops / second, and keep stirring after the dropwise addition After 12 hours, lower to room temperature, add 1M sodium hydroxide solution, adjust the pH of the solution to 10, heat to reflux for 6 hours, stop the reaction, lower to room temperature, adjust the pH of the solution to 6.5 with 1M hydrochloric acid, rotary steam at 50°C, and wash with water Twice, recrystallized with ethanol to obtain a reactive weather resistant agent.

Embodiment 2

[0055] Preparation of reactive weathering agent:

[0056] Mix 0.15mol 2-(2'-hydroxy-5-methylphenyl)benzotriazole, 25mL methylhydroquinone, 0.15mol triethylamine and 80mL tetrahydrofuran, and stir at 55°C to make 2-(2 '-Hydroxy-5-methylphenyl) benzotriazole is completely dissolved, then add dropwise 50mL THF solution dissolved with 0.15mol methyl malonyl chloride, the dropping rate is 3 drops / second, continue to stir after the dropwise addition After 12 hours, lower to room temperature, add 1M sodium hydroxide solution, adjust the pH of the solution to 11, heat to reflux for 6 hours, stop the reaction, lower to room temperature, adjust the pH of the solution to 7 with 1M hydrochloric acid, spin evaporate at 50°C, wash with water Twice, recrystallized with ethanol to obtain a reactive weather resistant agent.

Embodiment 3

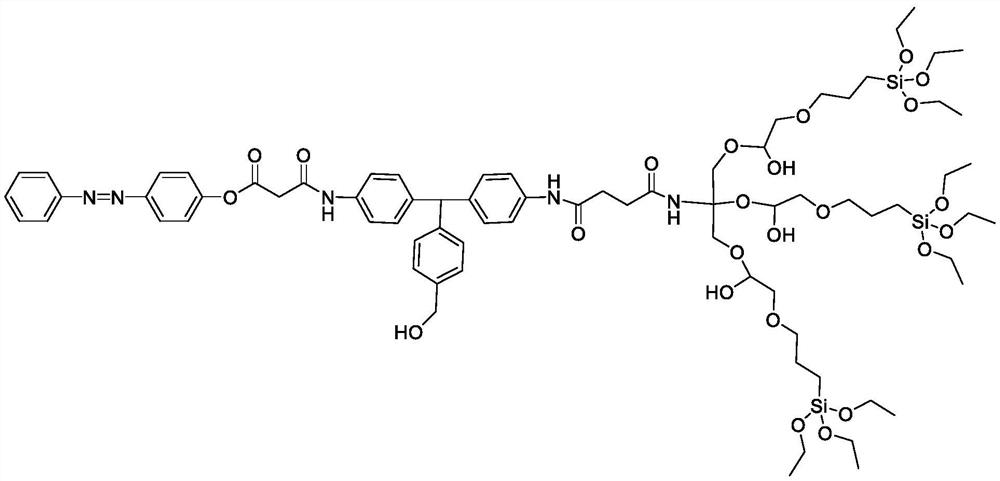

[0058] Preparation of azobenzene derivatives:

[0059] Mix 0.1mol 4-hydroxyazobenzene, 0.11mol malonic acid and 70mL tetrahydrofuran evenly, add 0.61g p-toluenesulfonic acid, heat and reflux under stirring for 5h, stop the reaction, filter and dry the crude product with 70mL acetic anhydride Recrystallized twice to obtain azobenzene derivatives.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com