Antibacterial coating liquid as well as preparation method and application thereof

A technology of antibacterial coating and organic antibacterial agent, which is applied in the field of antibacterial coating liquid and its preparation, can solve the problems of weak activity, weak absorption, dead corners of hygiene, etc., and achieve the effect of long-lasting effect, stable performance and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

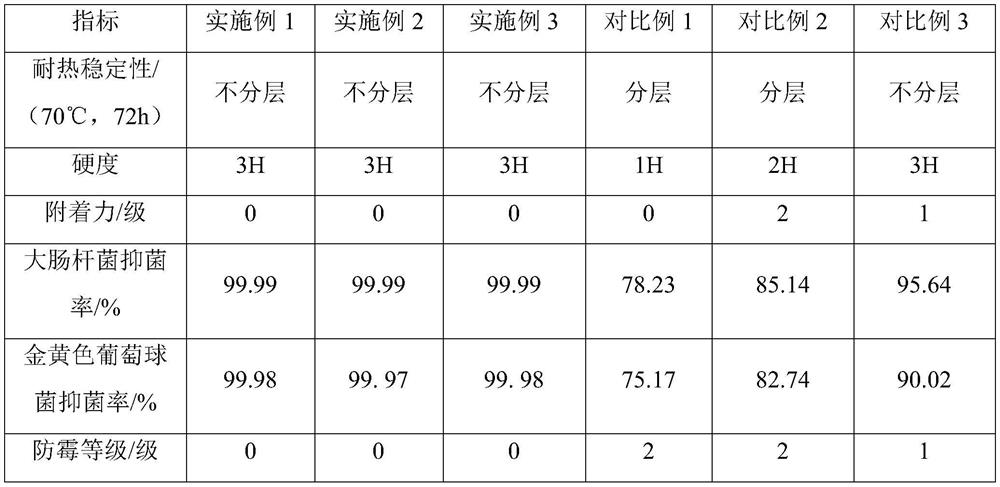

Examples

Embodiment 1

[0044] The antibacterial coating solution described in Example 1, in parts by weight, includes the following raw materials: 1.0 part of organic antibacterial agent, 0.5 part of inorganic antibacterial agent, 1 part of alcohol ester-12, 0.4 part of emulsified methyl silicone oil, allyl 0.5 part of base-3-methylimidazolium chloride, 30 parts of silicone-acrylic emulsion, and 27 parts of water; wherein, the organic antibacterial agent is N-[(2-hydroxy-3-trimethylammonium)propanyl] chloride A mixture of polysaccharide, polyhexamethylene monoguanidine hydrochloride, dodecylguanidine monohydrochloride, isothiazolinone and salicylanilide; the inorganic antibacterial agent is modified nanometer zinc oxide and nanometer A mixture of cerium oxides.

[0045] in:

[0046] The organic antibacterial agent, in parts by weight, is composed of the following raw materials: 40 parts of N-[(2-hydroxy-3-trimethylammonium) propanyl] chitosan (HTCC) chloride, polyhexamethylene 22 parts of monoguan...

Embodiment 2

[0070] The antibacterial coating solution described in Example 2, in parts by weight, includes the following raw materials: 0.8 part of organic antibacterial agent, 0.4 part of inorganic antibacterial agent, 0.7 part of alcohol ester-12, 0.4 part of emulsified methyl silicone oil, allyl 0.6 part of base-3-methylimidazolium chloride, 27 parts of silicone-acrylic emulsion, and 25 parts of water; wherein, the organic antibacterial agent is N-[(2-hydroxy-3-trimethylammonium)propanyl] chloride A mixture of polysaccharide, polyhexamethylene monoguanidine hydrochloride, dodecylguanidine monohydrochloride, isothiazolinone and salicylanilide; the inorganic antibacterial agent is modified nanometer zinc oxide and nanometer A mixture of cerium oxides.

[0071] in:

[0072] The organic antibacterial agent, in parts by weight, is composed of the following raw materials: 44 parts of N-[(2-hydroxy-3-trimethylammonium) propanyl] chitosan (HTCC) chloride, polyhexamethylene 20 parts of monogu...

Embodiment 3

[0096] The antibacterial coating solution described in Example 3, in parts by weight, includes the following raw materials: 0.7 part of organic antibacterial agent, 0.5 part of inorganic antibacterial agent, 0.8 part of alcohol ester-12, 0.5 part of emulsified methyl silicone oil, allyl 0.7 part of base-3-methylimidazolium chloride, 29 parts of silicone-acrylic emulsion, and 26 parts of water; wherein, the organic antibacterial agent is N-[(2-hydroxy-3-trimethylammonium)propanyl] chloride A mixture of polysaccharide, polyhexamethylene monoguanidine hydrochloride, dodecylguanidine monohydrochloride, isothiazolinone and salicylanilide; the inorganic antibacterial agent is modified nanometer zinc oxide and nanometer A mixture of cerium oxides.

[0097] in:

[0098] The organic antibacterial agent, in parts by weight, is composed of the following raw materials: 42 parts of N-[(2-hydroxy-3-trimethylammonium) propanyl] chitosan (HTCC) chloride, polyhexamethylene 24 parts of monogu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com