Application of sodium carboxymethyl cellulose in improvement of amoxicillin colistin sulfate injection

A technology of sodium carboxymethyl cellulose and amoxicillin sulfuric acid, which can be applied to non-active ingredients in medical preparations, antibacterial drugs, liquid delivery, etc., can solve problems such as unfavorable drug filling, reducing foam volume, and abundant foam. , to achieve the effect of shortening grinding time, improving selectivity and increasing bioavailability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1. Prescription

[0028] Raw materials: amoxicillin 12%, colistin sulfate 1%;

[0029] Excipients: aluminum stearate 0.5% (suspension agent 1), Span-80 0.5% (wetting agent), vitamin E 0.5% (antioxidant), carboxymethylcellulose sodium 0.2% (suspension agent 2 ), the balance is white oil (dispersion medium).

[0030] 2. Preparation process:

[0031] (1) Dissolving or dispersing the suspending agent 1 and the antioxidant in the prescribed amount in an appropriate amount of dispersing medium to prepare (1) liquid;

[0032] (2) Disperse the prescribed amount of wetting agent in an appropriate amount of dispersion medium, and then add amoxicillin and colistin sulfate to prepare (2) liquid;

[0033] (3) Pour an appropriate amount of dispersion medium into the colloid mill, and then slowly add the above liquid (1).

[0034] (4) Add suspending agent 2 sodium carboxymethyl cellulose, add liquid (2) while stirring, and start grinding after adding the drug.

[0035] (5) After ...

Embodiment 2

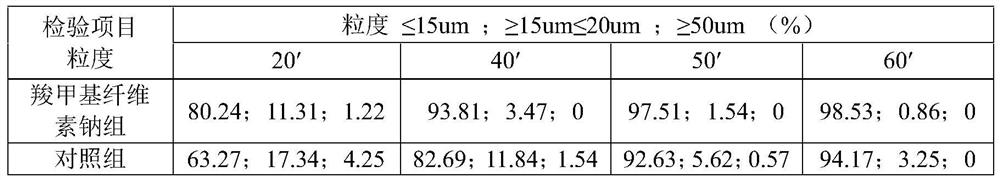

[0036] The impact of embodiment 2 carboxymethylcellulose sodium on the grinding time of amoxicillin colistin sulfate injection

[0037] Sodium carboxymethylcellulose group:

[0038] The preparation was prepared according to the prescription and configuration process of Example 1, wherein the grinding time was 20 minutes, 40 minutes, 50 minutes and 60 minutes respectively.

[0039] Control group without sodium carboxymethylcellulose:

[0040] Prescription: raw materials: amoxicillin 12%, colistin sulfate 1%;

[0041] Excipients: 0.5% aluminum stearate (suspending agent 1), 0.5% Span-80 (wetting agent), 0.5% vitamin E (antioxidant), and white oil (dispersing medium) as the balance. Configuration process except not adding suspending agent 2 carboxymethyl cellulose sodium in step (4), other are all identical with carboxymethyl cellulose sodium group.

[0042] The influence of table 1 sodium carboxymethyl cellulose on preparation milling time and particle size

[0043]

[00...

Embodiment 3

[0045] Embodiment 3 grinding effect comparison

[0046] Carry out steps (1) to (4) according to the configuration process of the sodium carboxymethylcellulose group and the control group, the grinding time is 40 minutes, and stand for 10 minutes after grinding.

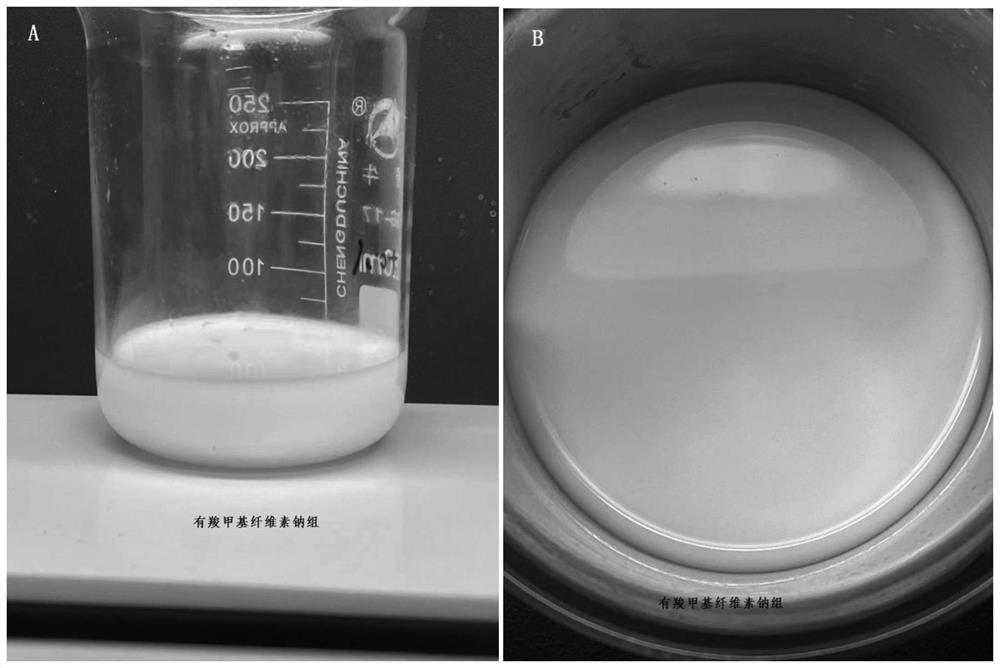

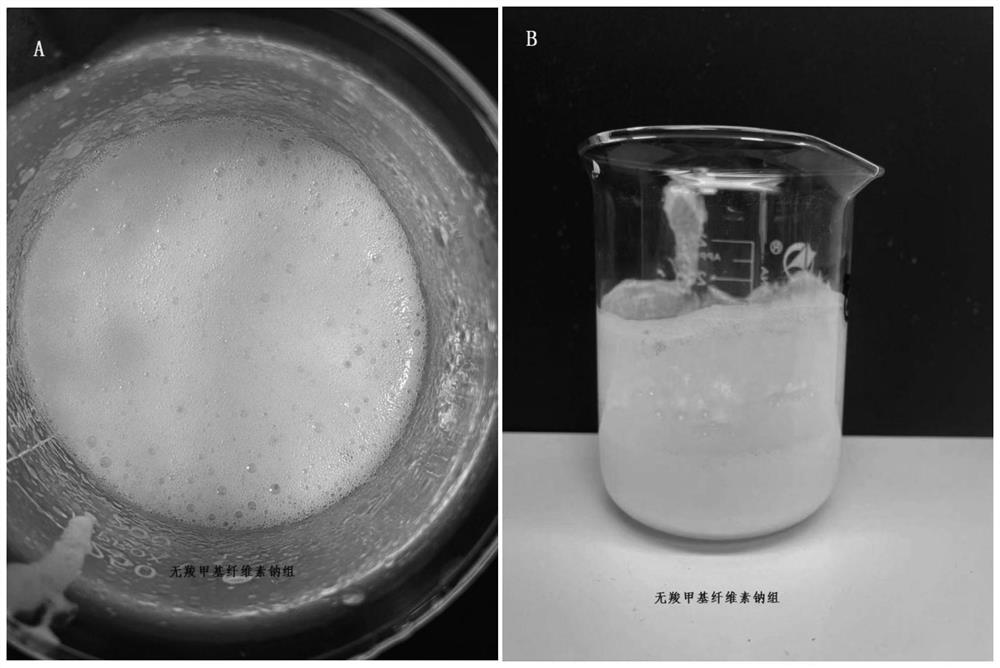

[0047] The foam situation after placement of sodium carboxymethyl cellulose group and control group is as follows: figure 1 and figure 2 shown. The results showed that the foam in the preparation of the control group was abundant, and a large amount of foam was all arranged on the container wall and the surface of the preparation; while the sodium carboxymethyl cellulose group had no foam.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com