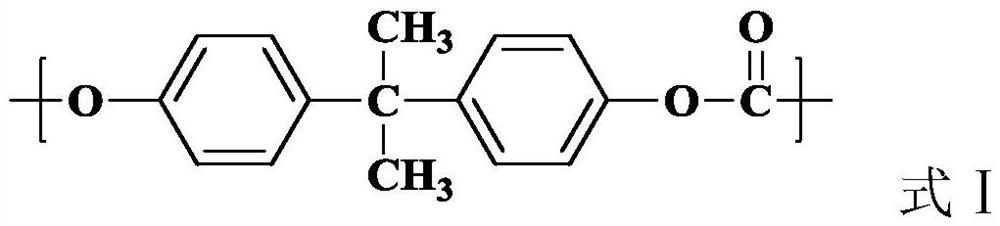

Copolymerized polycarbonate and preparation method thereof

A technology of polycarbonate and copolymerization, which is applied in the field of copolycarbonate and its preparation, can solve the problems of the comprehensive use performance of materials, poor moisture and heat aging resistance, and influence on the mechanical properties of materials, and achieve good industrial application prospects and easy steps Operation, the effect of improving intrinsic flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

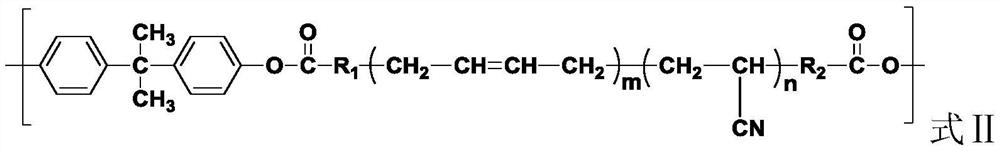

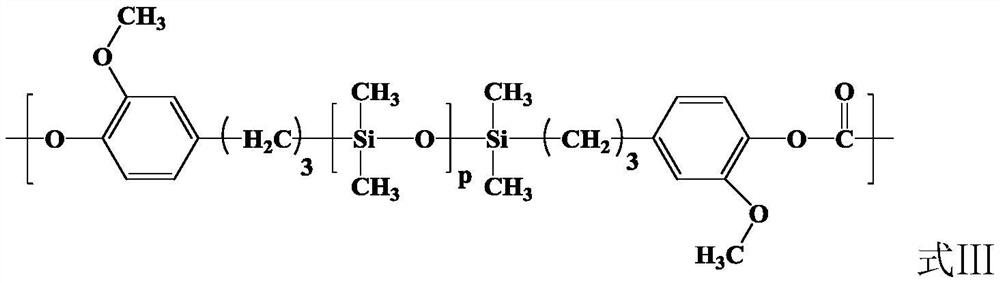

Method used

Image

Examples

Embodiment 1

[0074] Add 2280g of bisphenol A (BPA), 1000g of sodium hydroxide, 47g of p-cyanophenol, 12.8g of 1,1,1-tris-(4-hydroxyphenyl)ethane (THPE) into a nitrogen-protected mixer , 7200g of water, mixed evenly; after completely dissolving, add 12.9g of catalyst tetrabutylammonium bromide, form sodium phenate salt phase;

[0075] In another mixer, add 1139g liquid phosgene and 22770g dichloromethane (MC), and mix the two evenly to form a phosgene solution with a mass concentration of 4.76%; get another mixer and add 640g LNBR-2 and 2562g dichloromethane Chloromethane, and the two are mixed uniformly to form a carboxyl-terminated polybutadiene acrylonitrile solution with a mass concentration of 20%, as a comonomer solution;

[0076] Subsequently, put the sodium phenolate salt phase into the polymerization reactor, add the prepared phosgene solution and the comonomer solution into the polymerization reactor respectively at a stirring rate of 550 rpm, and at the same time, dropwise add th...

Embodiment 2-14 and comparative example 1-3

[0078] Copolycarbonate was prepared in the same manner as in Example 1, except that the amount of feed was changed (as shown in Table 1). Wherein, each embodiment and comparative example have the addition of liquid phosgene, carboxyl-terminated polybutadiene acrylonitrile, and eugenol-terminated PDMS monomers, and then keep the mass concentrations of their prepared solutions at 4.76%, 20%, and 20% respectively .

[0079] Table 2, embodiment and comparative example feeding parameters

[0080]

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com