Method for preparing anode plate by fire refining of complex copper-containing material

A technology of pyro-refining and copper materials, applied in the field of pyro-metallurgical process, which can solve the problems of process flow, equipment investment that cannot meet the needs of enterprises, lack of slag returning to the front-end process, large amount of pyro-refining slag, etc., to achieve production costs Low, good fluidity, high copper direct yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

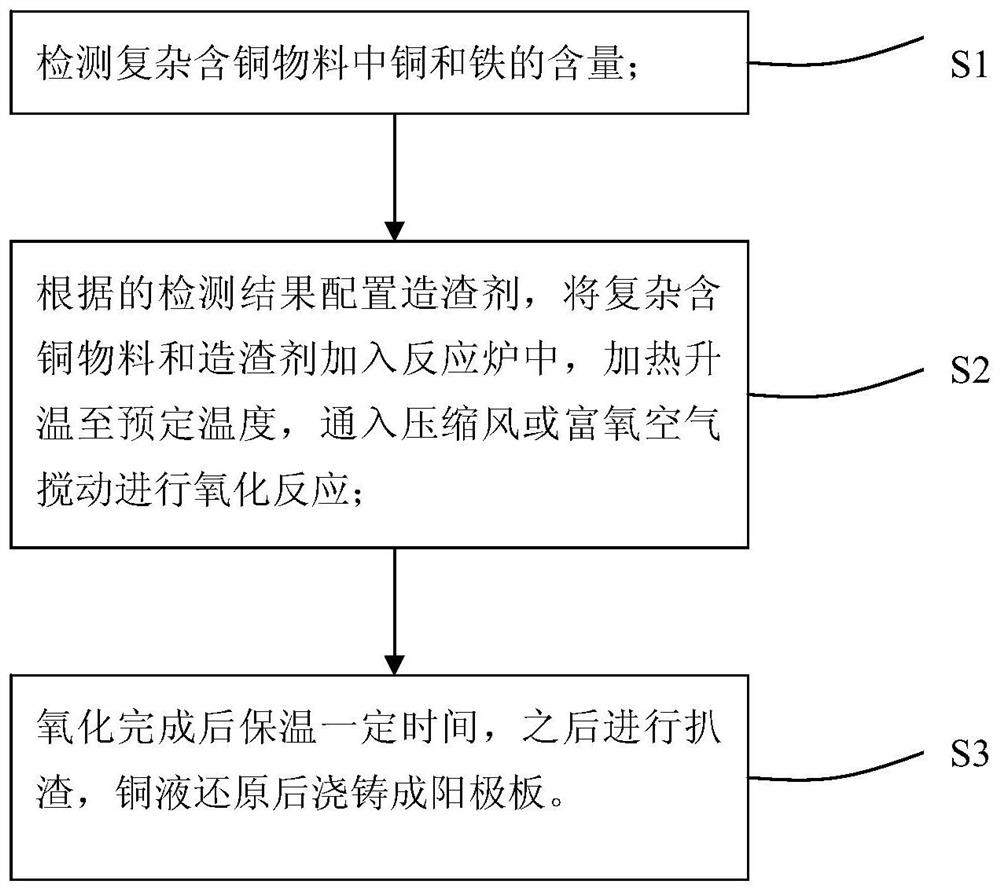

Method used

Image

Examples

Embodiment 1

[0044] Single-furnace high-grade complex copper material has a total of 308.25 tons. After detecting 95.49% of copper, 2.03% iron containing iron, the total amount of impurities is 13.90 tons, which is equipped with 10 tons of dragging agent, of which sand (silica content is 99.5%) 8 Tons, limestone (39.5% calcium content, calcium oxide 55.3%) 12 tons, high-grade complex copper materials and slag, allocated 3 batches, 1,200 ° C, furnace temperature, total application 16.10 hours, using silica High-grade complicated copper-containing removal effect increased, so that the slag level increased by 12.79%, adding calcium oxide, so that the floating fluidity is better, the viscosity is lower, the feed is introduced into the compressive wind acceleration material melt. At the same time, oxidation is carried out, and the subsequent oxidation time is 5.2 hours. After the insulation is allowed to stand for 30 minutes. After that, the pulverization was subjected to 0.7 hours, and the natural...

Embodiment 2

[0046] Single furnace high-grade complex copper-containing material has a total of 300.00 tons. After detecting 92.50%, the total amount of impurities is 22.5 tons, with a total of 8 tons of dragging agents, including sand (silica content of 99.5%) 3 tons, limestone (including limestone Calcium 39.5%, corresponding calcium oxide 55.3%) 5 tons, high-grade complex copper materials and dragging agents are divided into 3 batches, the furnace temperature is 1200 ° C, and the total use of 13.4 hours. The addition of the compressive wind acceleration material merges, while oxidation, the subsequent oxidation time is 3.6 hours, using the high-grade of the silica high-grade complicated copper material to improve the removal effect of oligible iron, lead, and zinc, add calcium oxide, so that the slag flows Better, lower viscosity. After the insulation is allowed to stand for 30 minutes. After that, the pulverization was subjected to 0.7 hours, and the natural copper settled in the slag was ...

Embodiment 3

[0048] Single furnace high-grade complicated copper material has a total of 305.78 tons. After detecting 96.45% of copper, 10.86 tons of impurities, a total of 5 tons of dragging agent, including sand (silica content of 99.5%) 2 tons, limestone (including limestone Calcium 39.5%, corresponding to calcium oxide 55.3%) 6 tons, high-grade complicated copper material and slag which are divided into 3 batches, 1,200 ° C, and the total cost is 14.6 hours. The addition of compressive wind acceleration materials in the later period, while oxidation, follow-up oxidation time of 5.6 hours. After the insulation is allowed to stand for 30 minutes. Then, the coal was subjected to 0.7 hours, then the copper fluid cast into an anode plate. Finally, the total amount of slag is 16.64 tons, and the slag grade increases by 17.81%. Pouring 288.35 tons of Qigang Antiode plate, such as figure 1 Indicated.

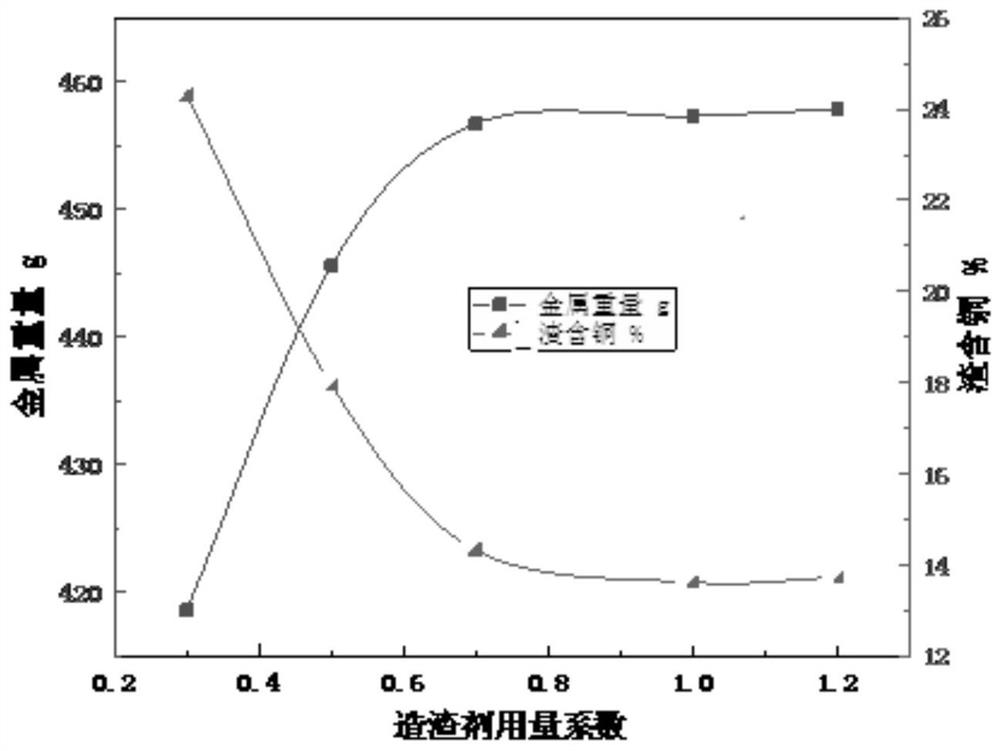

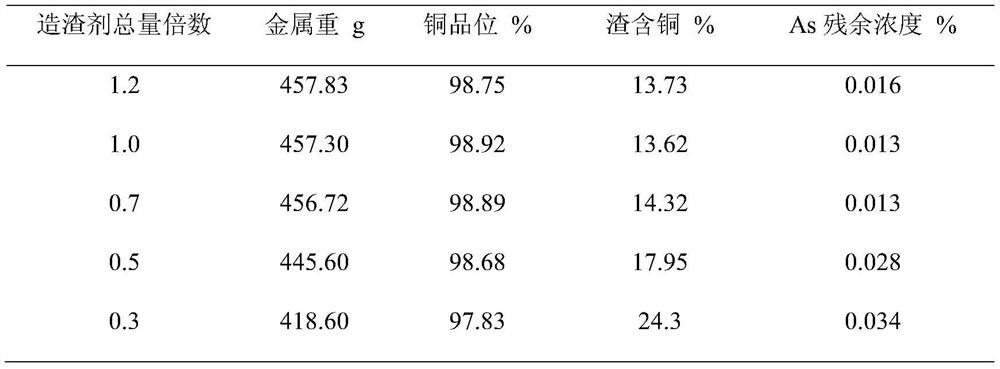

[0049] Table 5-7 1 Samples of different standrings on the total amount of slag copper

[0050] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com