Catalyst composition for ethylene oligomerization

An ethylene oligomerization and catalyst technology, applied in the direction of catalysts, hydrocarbons, hydrocarbons, etc., can solve the problems of high polyolefin content and difficult to achieve continuous production of ethylene tetramerization, and achieve high selectivity and inhibition of polyethylene side effects. production, improve selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

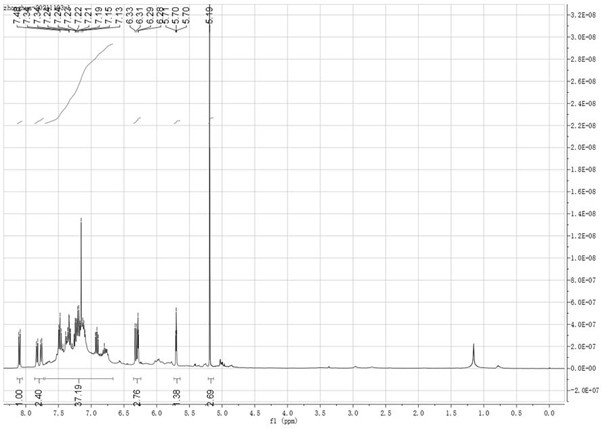

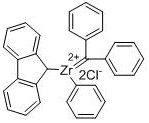

[0034] Embodiment 1 Preparation of diphenylmethylene (cyclopentadiene) (9-fluorenyl) zirconium dichloride:

[0035]

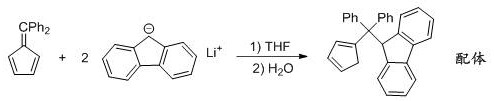

[0036] The synthetic route of white compound ligand

[0037] 1) Add 2.5 g (0.015 mol) of fluorene and 50 mL of THF to a round bottom flask equipped with a sidearm, addition funnel, and magnetic stir bar. An equimolar amount of methyllithium in diethyl ether (1.4 M) to fluorene was added at room temperature within 30 minutes. The resulting dark red solution was stirred for several hours until gas evolution had completely ceased. Then, 3.4 g (0.015 mol) of 6,6-diphenylfulvene dissolved in 100 mL THF was added dropwise, and the resulting red THF solution was stirred overnight, followed by adding 30 mL of ammonium chloride saturated aqueous solution and stirring for 10 minutes. The organic layer was extracted several times with 50 ml of ether, and the combined organic phases were dried over magnesium sulfate. After removal of ether and recrystallization of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com