Non-destructive cleaning method for rust on surface of copper object

A technology of object surface and copper, applied in the direction of using liquid cleaning methods, cleaning methods and utensils, chemical instruments and methods, etc., can solve problems such as substrate damage, achieve clear lines and reduce mechanical losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

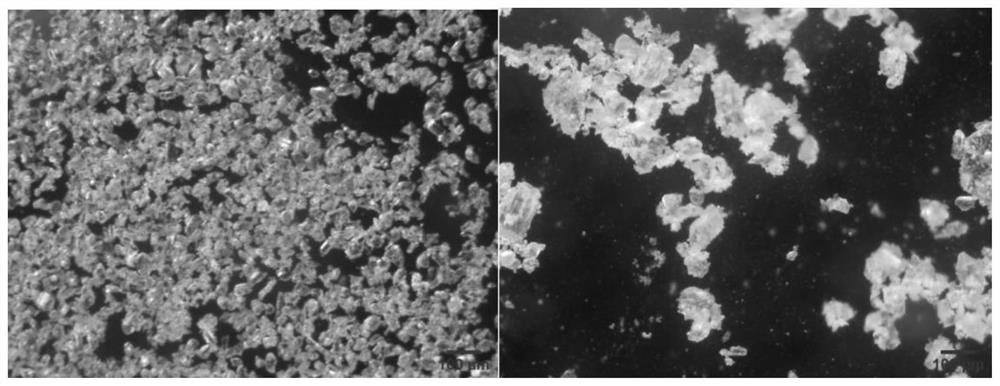

[0030] The preparation of embodiment 1 sodium bicarbonate crystal particle abrasive

[0031] Weigh 100 grams of sodium bicarbonate crystals, grind them for 10 minutes, and then pass through 150 mesh, 200 mesh, 325 mesh, 500 mesh and 600 mesh sieves and classify and sieve, retain 19 grams of crystals on the 600 mesh sieve, particle size 20um ~25um, 17g of partial crystals retained on 500 mesh sieve, particle size 26um~30um, 18g of partial crystals retained on 325 mesh sieve, particle size of 31um~45um Among them, 16 grams of partial crystals retained on 200 mesh sieve grams, particle size 46um-75um, 15 grams of partial crystals retained on the 150-mesh sieve, particle size 76um-100um, of which 200 mesh corresponds to 75um, and 500 mesh corresponds to 30um. (See figure 2 )

Embodiment 2

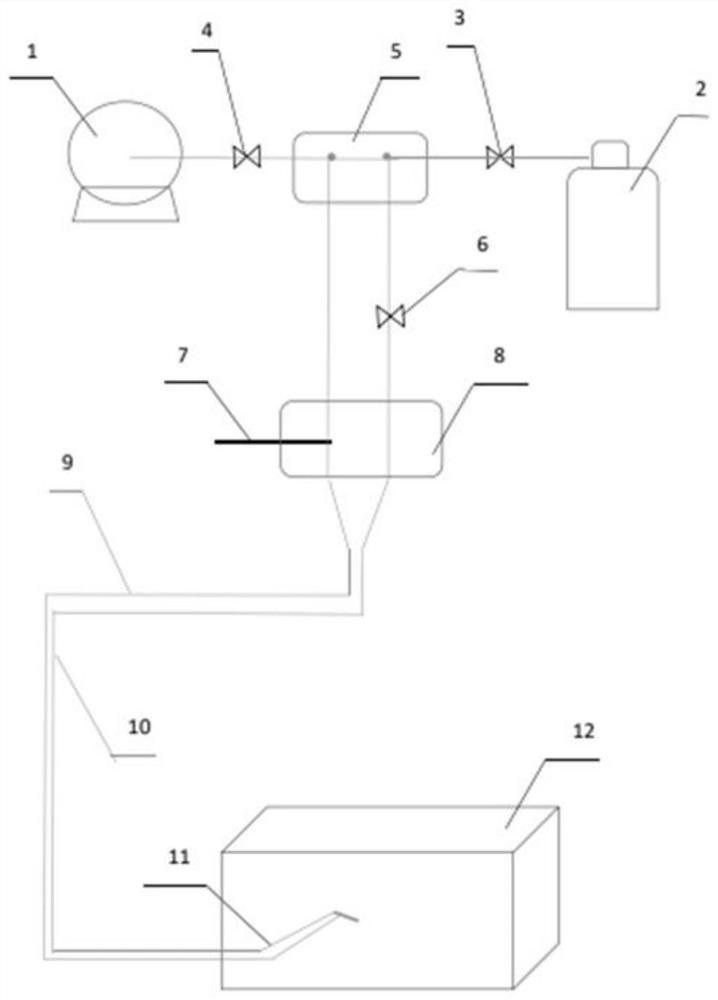

[0033] Such as figure 1 Shown, a kind of cleaning device, this cleaning device comprises air compressor 1, deionized water tank 2, turbine 5, sodium bicarbonate abrasive feed inlet 7, gas-solid-liquid mixing sandblasting machine 8, gas-solid mixing pipeline 9 , a gas-liquid mixing pipeline 10, a hand-held gas-solid-liquid mixing spray gun 11 and a cleaning operation room 12, the air compressor 1 and the deionized water tank 2 are respectively connected to the turbine 5 through a branch, and then the parallel air is separated through the branch. The solid mixing pipeline 9 and the gas-liquid mixing pipeline 10 are connected to the gas-solid-liquid mixing sandblasting machine 8, and the gas-solid mixing pipeline 9 and the gas-liquid mixing pipeline 10 are arranged side by side and jointly connected with the hand-held gas-solid-liquid mixing spray gun 11 and juxtaposed In the cleaning operation room 12.

[0034] The steps of a non-destructive cleaning method for surface corrosio...

Embodiment 4

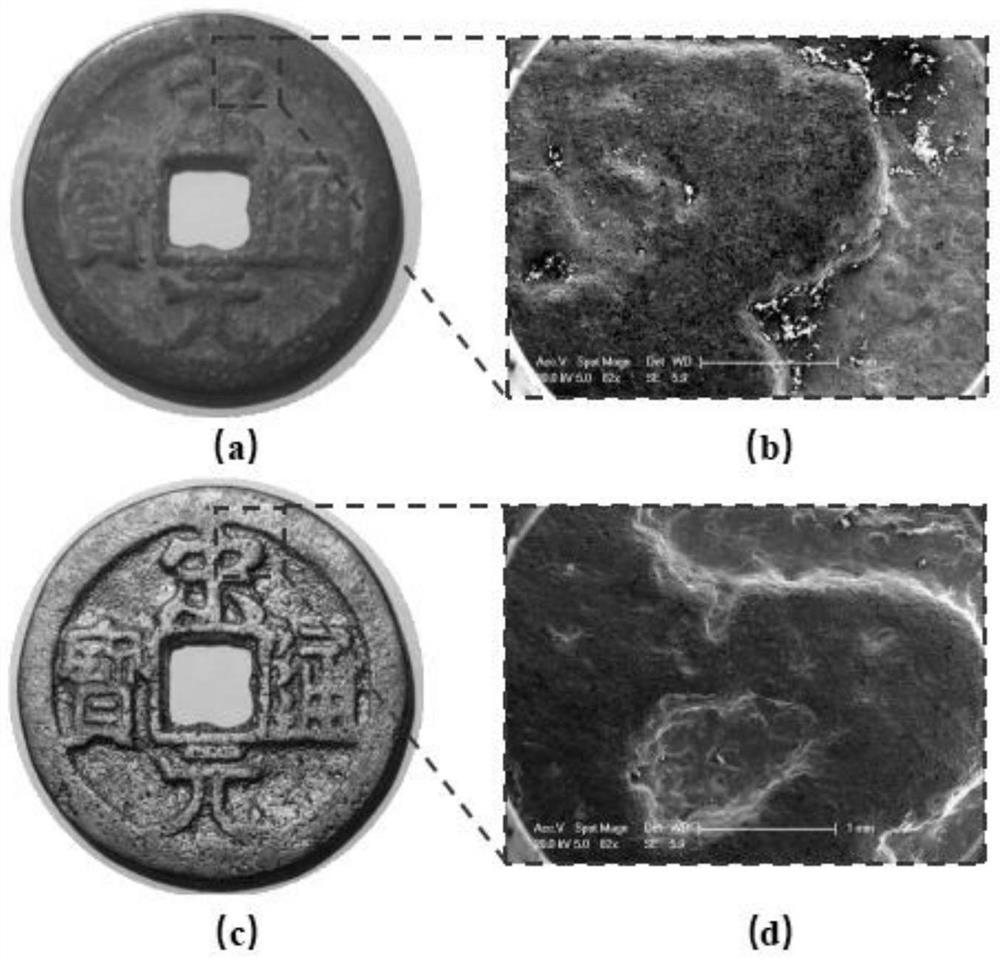

[0051] The non-destructive cleaning method of the surface corrosion of embodiment 4 copper coins

[0052] 1) Pre-cleaning stage: Start the air compressor, control the compressed air pressure to 0.4MPa, open the valve, pass the deionized water stored in the cleaning liquid tank into the turbine through the water inlet pipeline, and the deionized water and compressor air pass through The gas-solid-liquid sandblasting machine reaches the nozzle, and the copper coins 3 to be cleaned are placed in the cleaning room and the parts of the copper cultural relics are spray-cleaned through the hand-held mixing nozzle.

[0053] 2) Intermediate cleaning stage: close the valve of the cleaning liquid tank, open the sodium bicarbonate abrasive feed port, use 200-mesh sodium bicarbonate abrasive to feed, the compressed air and sodium bicarbonate abrasive are mixed through the gas-solid-liquid sandblasting machine to reach the nozzle Place the copper coin 3 to be cleaned in the cleaning box to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com