High-comfort fiber antibacterial composite fabric and preparation method thereof

A composite fabric and comfortable technology, applied in fiber chemical characteristics, chemical instruments and methods, rayon manufacturing, etc., can solve problems such as mites, bacterial growth, poor water absorption of fabrics, and wet surfaces, and achieve a cool smell effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

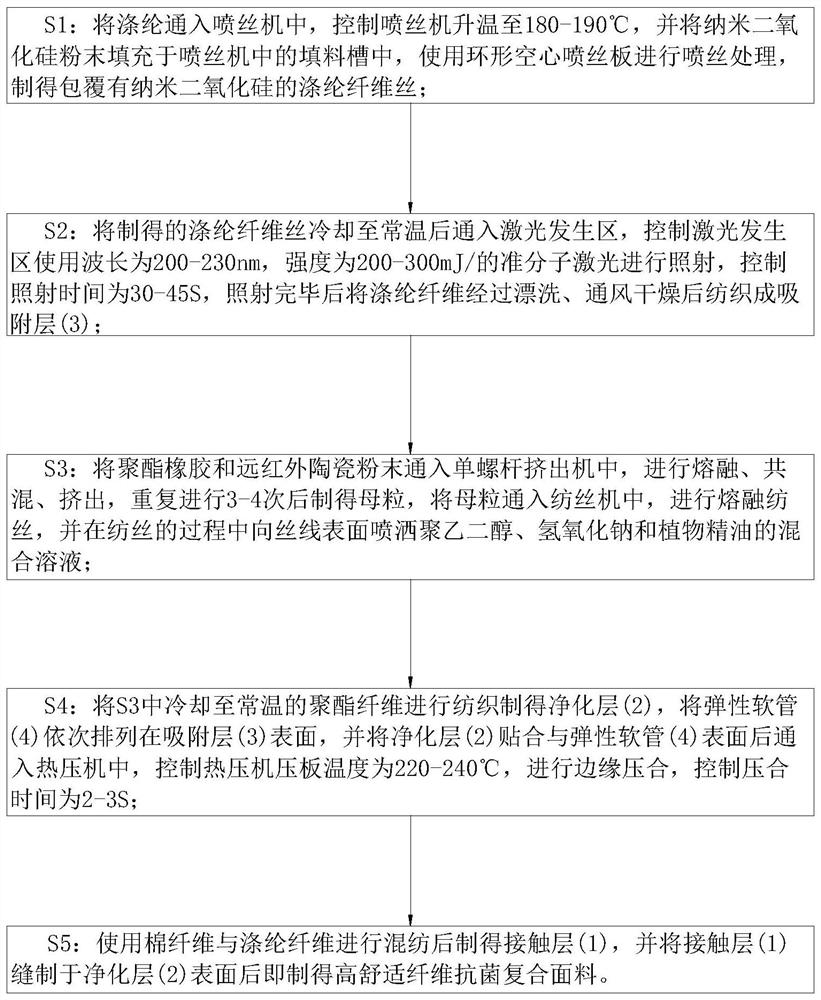

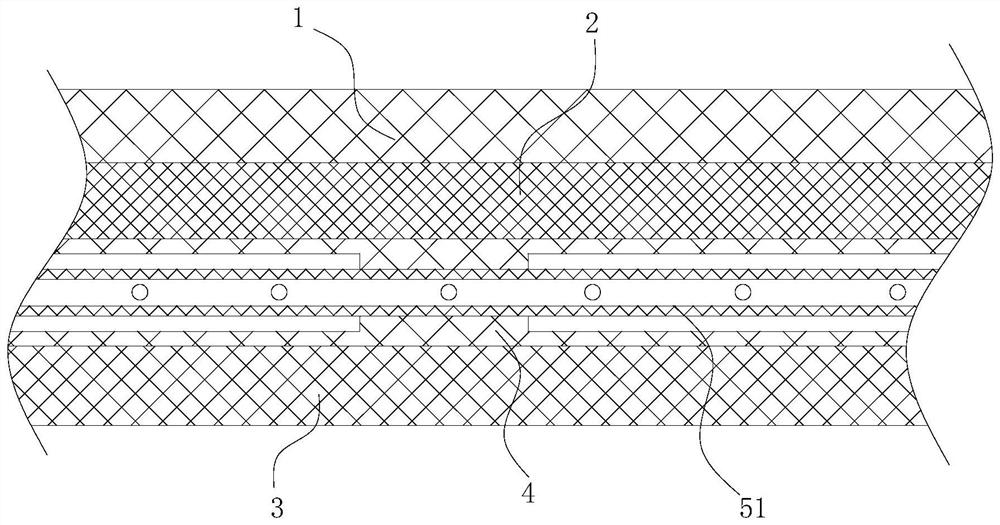

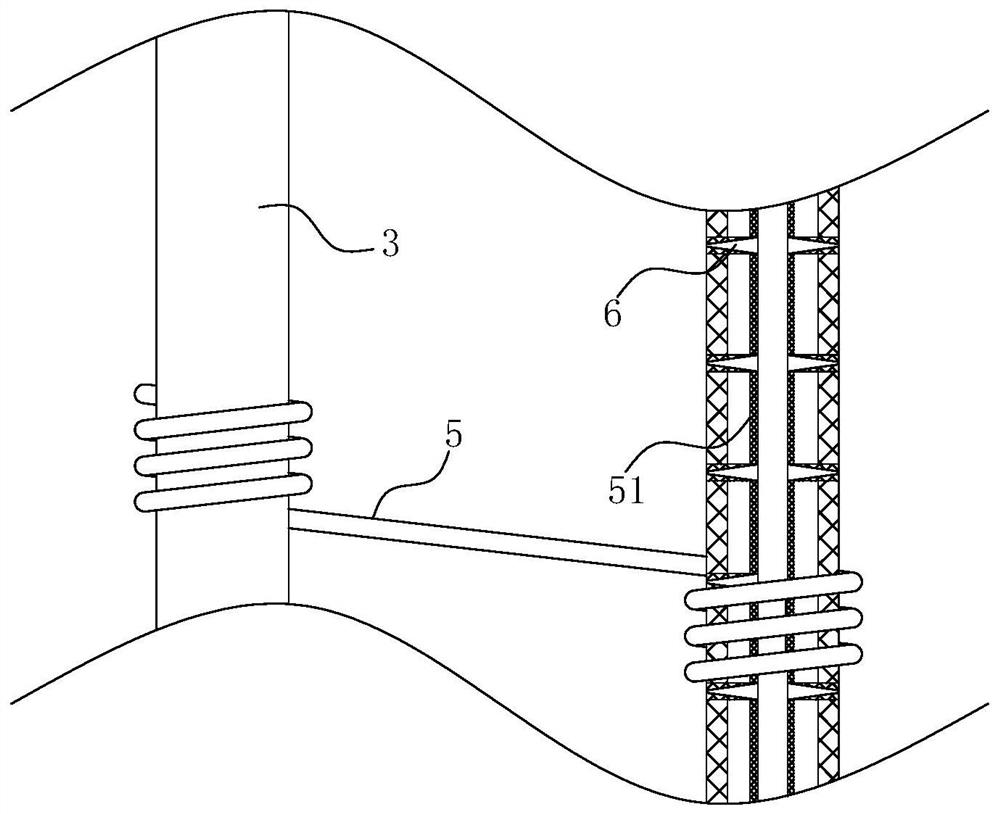

[0038] As an embodiment of the present invention, the high-comfort fiber antibacterial composite fabric also includes an adsorption layer 3; the adsorption layer 3 is made of polyester fibers coated with nano-silica; The spinneret is coated with nano-silica powder and prepared by solvent-spinning; the polyester fiber is modified by laser before weaving; , the intensity is 200-300mJ / cm 2 The excimer laser is used for irradiation, and the irradiation time is controlled to be 30-45S;

[0039] When working, the polyester fiber is sprayed by using the annular hollow spinneret, and the nano-titanium dioxide is filled in the inner diameter of the polyester fiber. Under the irradiation of the excimer laser, the laser has a penetrating effect on the surface polyester, but the laser is continuously moving. During the process, it is refracted and reflected by nano-titanium dioxide, which effectively prevents the fiber from breaking during the irradiation of the excimer laser on the fibe...

Embodiment 1

[0053] The fabric includes a contact layer, a purification layer and an adsorption layer; the contact layer is made of cotton fiber and polyester fiber; both the purification layer and the adsorption layer are made of polyester; the contact layer, the purification layer and the adsorption layer After being soaked in antibacterial agent for 3-5 hours, the fabrics were made by rinsing and drying, and the fabrics were adhered to each other. Repeat the above arrangement to make three pieces of fabrics, marked as A1-A3;

[0054] Lay three pieces of fabrics in the room, and choose three people with similar height and weight to lie flat on the fabrics. The difference between temperature and humidity, take the average value and record and output the data;

[0055] Table 1

[0056]

Embodiment 2

[0058] The fabric includes a contact layer and a purification layer; the contact layer is made of cotton fiber and polyester fiber; the purification layer consists of the following raw materials:

[0059] 15 parts of polyester rubber, 2 parts of polyethylene glycol, 0.5 parts of sodium hydroxide, 2 parts of far-infrared ceramic powder, 5 parts of plant essential oil;

[0060] The particle size of the far-infrared ceramic powder is 0.02-0.05mm;

[0061] Pass the polyester into the spinneret, control the temperature of the spinneret to 180°C, fill the nano-silica powder in the filler tank in the spinneret, and use the annular hollow spinneret for spinning treatment to obtain the bag Polyester fiber filaments covered with nano-silica, cooled to room temperature and then passed into the laser generating area, the laser generating area is controlled to use a wavelength of 200nm and an intensity of 300mJ / cm 2 The excimer laser is irradiated, and the irradiation time is controlled t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com