Cyclic peptide glass and pharmaceutical composition glass containing cyclic peptide

A technology of composition and cyclic peptide, which is applied in the field of medicine, can solve the problems of unpublished reports of cyclic peptide glass, which have not been disclosed, and achieve high thermal/chemical stability, increase the dissolution rate of drugs, and reduce the effects of drug side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0106] A kind of preparation method of the cyclopeptide glass based on cyclosporine A (CsA) comprises the steps:

[0107] (1) Put the CsA powder in a ball mill to grind evenly, control the constant temperature of the ball mill to 25°C, and then transfer it to a crucible;

[0108] (2) Place the crucible containing CsA powder in step (1) under N 2 placed in the heating equipment under the atmosphere;

[0109] (3) heat treatment is carried out to the equipment of step (2), with 10Kmin -1 Raise the temperature of the crucible from room temperature to 573.15K at a heating rate of 20 minutes at this temperature;

[0110] (4) The equipment of step (3) is cooled down, with 10Kmin -1 Lower the crucible to an annealing furnace at 273.15K at a constant temperature for 30 minutes to anneal the glass to obtain CsA glass.

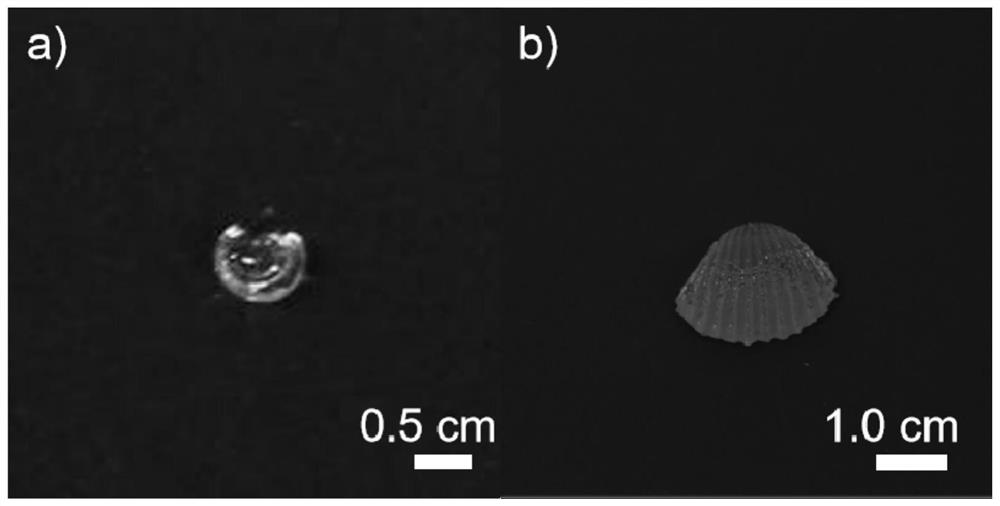

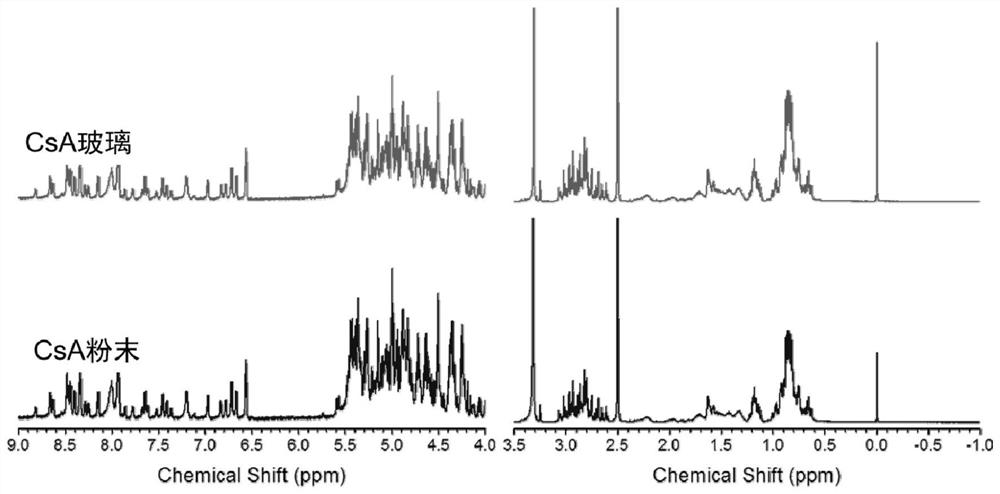

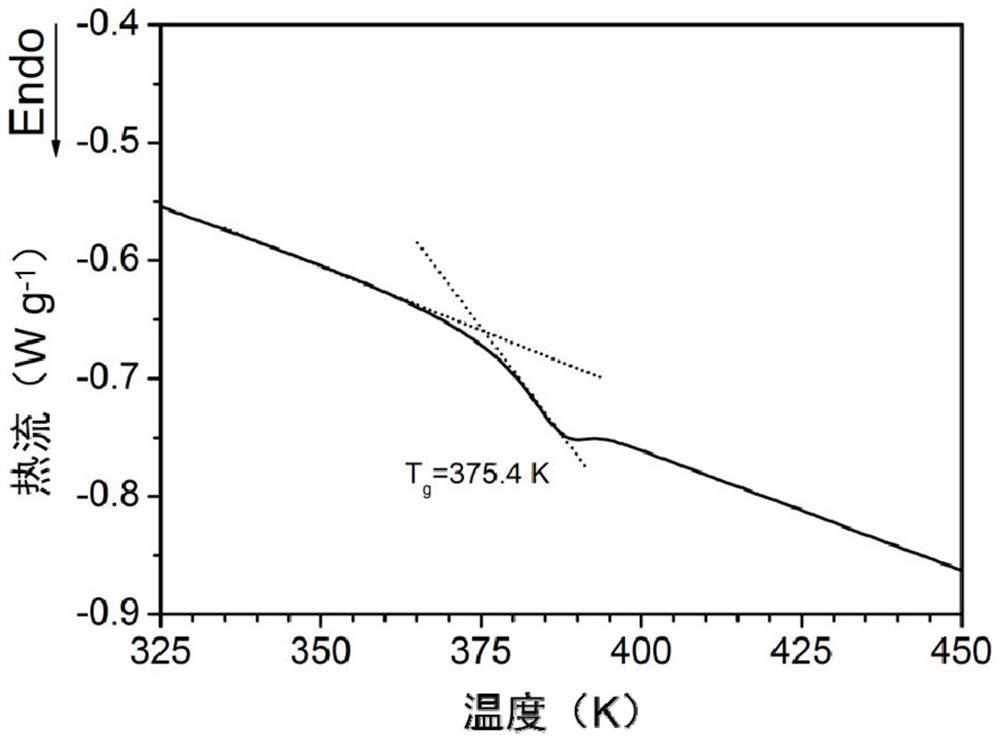

[0111] figure 1 The physical picture (a) of the CsA glass prepared in Example 1 at room temperature and the physical picture (b) of the CsA glass obtained by the po...

Embodiment 2

[0119] A kind of preparation method of the pharmaceutical composition glass based on phenylalanine-proline cyclic dipeptide (CFP) and paclitaxel (PTX) comprises the steps:

[0120] (1) Put the CFP powder in a ball mill to grind and mix evenly, control the constant temperature of the ball mill to 37°C, and then transfer it to a container;

[0121] (2) heat treatment is carried out to the container of step (1), with 20K min -1 The heating rate is to raise the temperature of the container from room temperature to 473.15K, and keep it warm for 30 minutes at this temperature;

[0122] (3) The container of step (2) is cooled down, with 10K min -1 The cooling rate reduces the container to a temperature of 333.15K;

[0123] (4) Put the PTX powder in a ball mill to grind evenly, control the constant temperature of the ball mill to 37°C, then add ethanol to completely dissolve, and the molar ratio of CFP to PTX is 25:1;

[0124] (5) Add the solution of step (4) dropwise into the cont...

Embodiment 3

[0134] A kind of preparation method of the pharmaceutical composition glass based on vancomycin, gramicidin S and penicillin comprises the steps:

[0135] (1) Put vancomycin, gramicidin S and penicillin in a ball mill, grind and mix evenly, control the constant temperature of the ball mill to 37°C, and then transfer to a container, the mass ratio of the three is 2:2:1;

[0136] (2) Add a mixed organic solvent of hexafluoroisopropanol and ethanol to the mixed powder in step (1), and stir until completely dissolved;

[0137] (3) The mixed solution obtained in step (2) is placed in a vacuum rotary evaporator, and the mixture is heated at 50K min -1 The heating rate is raised from room temperature to 443.15K temperature, and the temperature is kept at this temperature for 30 minutes to remove the organic solvent;

[0138] (4) The equipment of step (3) is cooled down, with 10K min -1 The cooling rate is reduced to 243.15K temperature, and the temperature is kept at this temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com