Anti-aging high-strength polyethylene fiber and preparation method thereof

A high-strength polyethylene and anti-aging technology, applied in the field of anti-aging high-strength polyethylene fibers and their preparation, can solve the problems of low melting point, easy creep of polyethylene fibers, and low activation energy of polyethylene fibers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

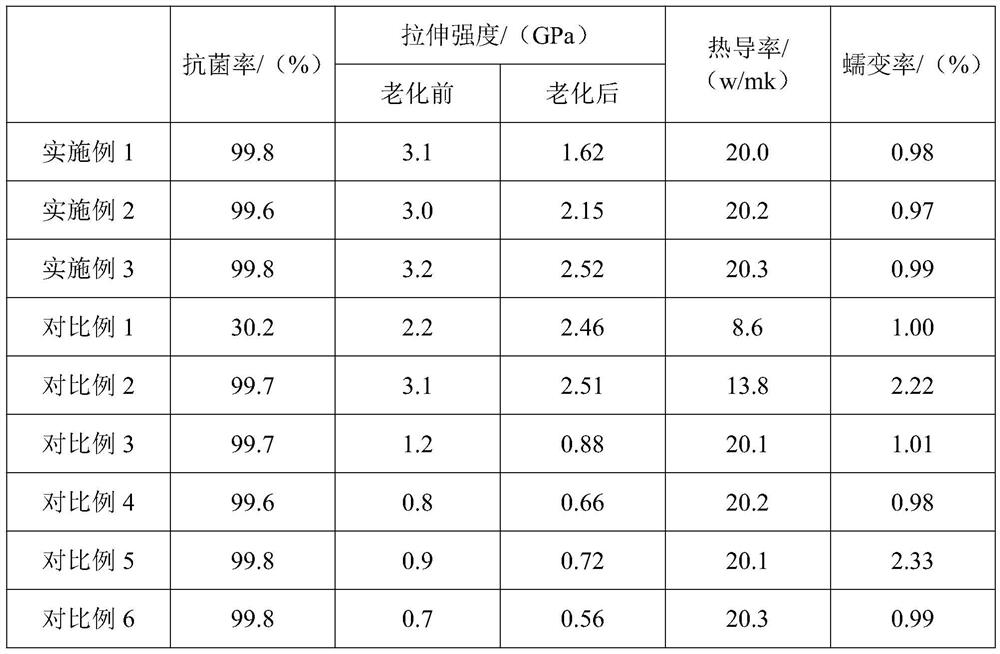

Examples

Embodiment 1

[0037] An anti-aging high-strength polyethylene fiber mainly includes 10 parts of shell fiber spinning solution, 23 parts of nuclear fiber spinning solution and 1000 parts of protease hydrolysis solution in parts by weight.

[0038]A preparation method of anti-aging high-strength polyethylene fiber, the preparation method of the anti-aging high-strength polyethylene fiber mainly includes the following preparation steps:

[0039] (1) Preparation of composite fiber with shell-core structure: mix polylactic acid and polyvinyl succinate twice the mass of polylactic acid, and then add dimethyl sulfoxide and polyvinyl succinate 30 times the mass of polylactic acid. Nano-alumina with 0.8 times the mass of lactic acid was ultrasonicated at 30kHz for 8s, stirred at 1200r / min for 30min, and dialyzed in water at 4°C for 4h using a dialysis bag with a molecular weight cut-off of 1500 to obtain microcapsules; Under ultrasonic conditions, mix ethylene, microcapsules, titanium tetrachloride,...

Embodiment 2

[0044] An anti-aging high-strength polyethylene fiber mainly includes 20 parts of shell fiber spinning solution, 46 parts of nuclear fiber spinning solution and 2000 parts of protease hydrolysis solution in parts by weight.

[0045] A preparation method of anti-aging high-strength polyethylene fiber, the preparation method of the anti-aging high-strength polyethylene fiber mainly includes the following preparation steps:

[0046] (1) Preparation of composite fiber with shell-core structure: mix polylactic acid and polyvinyl succinate with 2.5 times the mass of polylactic acid, and then add dimethyl sulfoxide and polyvinyl succinate with 30 times the mass of polylactic acid. Nano-alumina with 0.9 times the mass of lactic acid was ultrasonicated at 35kHz for 10s, stirred at 1300r / min for 30min, and dialyzed in water at 4°C for 4h using a dialysis bag with a molecular weight cut-off of 1500 to obtain microcapsules; at 35kHz Under ultrasonic conditions, mix ethylene, microcapsules...

Embodiment 3

[0051] An anti-aging high-strength polyethylene fiber mainly includes 30 parts of shell fiber spinning solution, 72 parts of nuclear fiber spinning solution and 3000 parts of protease hydrolysis solution in parts by weight.

[0052] A preparation method of anti-aging high-strength polyethylene fiber, the preparation method of the anti-aging high-strength polyethylene fiber mainly includes the following preparation steps:

[0053] (1) Preparation of composite fiber with shell-core structure: mix polylactic acid and polyvinyl succinate 3 times the mass of polylactic acid, then add dimethyl sulfoxide and polyvinyl succinate 30 times the mass of polylactic acid Nano-alumina with 1.0 times the mass of lactic acid was sonicated under 40kHz ultrasonic conditions for 12s, stirred at 1500r / min for 30min, and dialyzed in water at 4°C for 4h using a dialysis bag with a molecular weight cut-off of 1500 to obtain microcapsules; at 40kHz Under ultrasonic conditions, mix ethylene, microcapsu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com