A kind of epoxy resin waterproof coating for hydraulic engineering and preparation method thereof

A technology of epoxy resin and waterproof coating, applied in epoxy resin coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of small elongation at break, low elongation at break, and large internal stress of materials, etc. Achieve the effect of high elongation at break, high tensile strength and high mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

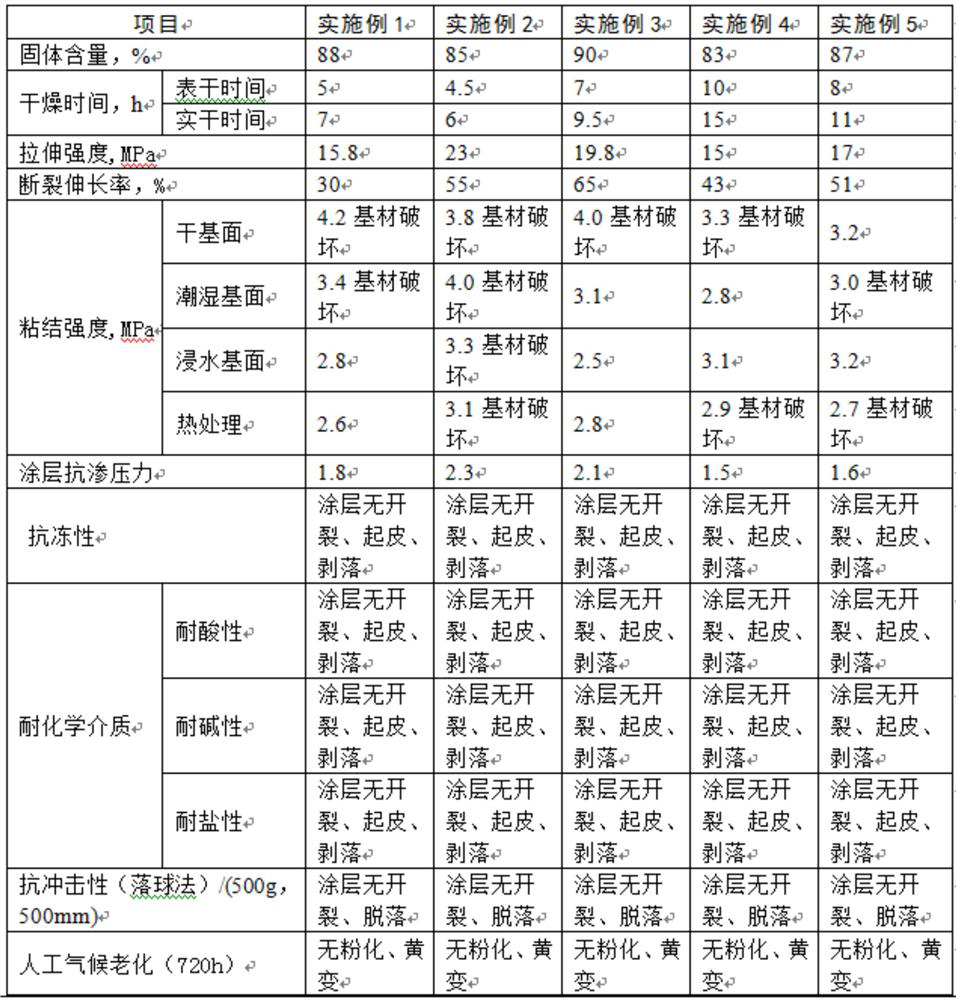

Examples

Embodiment 1

[0031] An epoxy resin waterproof coating for hydraulic engineering, comprising A component and B component, wherein, 40 parts of hydrogenated bisphenol A epoxy resin, 15 parts of polyurethane modified epoxy resin, 15 parts of epoxy resin toughening agent, 20 parts of high boiling point environmentally friendly solvent ethylene glycol diacetate (EGDA), 3 parts of coupling agent, 0.08 part of dispersant No. 1, 0.1 part of carbon black, 0.2 part of defoamer, 5 parts of titanium dioxide, and 0.05 part of dispersant No. 2 5 parts of sericite powder, 2 parts of fumed silica, 0.3 part of antioxidant additive 1010, and 0.3 part of anti-ultraviolet additive UV-327; component B includes the following components in parts by mass: polythiol 10 parts of curing agent, 3 parts of alicyclic amine curing agent, 0.3 part of accelerator, and 0.3 part of stopper.

[0032] Hydrogenated bisphenol A epoxy resin is a bright combination of EP-4080E hydrogenated epoxy resin and HE-2025 hydrogenated epo...

Embodiment 2

[0057] An epoxy resin waterproof coating for hydraulic engineering, comprising A component and B component, wherein, 55 parts of hydrogenated bisphenol A epoxy resin, 15 parts of polyurethane modified epoxy resin, 20 parts of epoxy resin toughening agent, 20 parts of diluent, 3 parts of coupling agent, 0.05 part of dispersant No. 1, 0.1 part of carbon black, 0.2 part of defoamer, 5 parts of titanium dioxide, 0.05 part of dispersant No. 2, 5 parts of sericite powder, gas phase dioxide 2 parts of silicon, 0.3 part of antioxidant 1010, 0.3 part of anti-ultraviolet auxiliary UV-327; component B includes the following components by mass: 8 parts of polythiol curing agent, 5 parts of alicyclic amine curing agent part, 0.3 part of accelerator, and 0.3 part of stopper.

[0058] The diluent is chemically resistant reactive diluent K100.

[0059] The cycloaliphatic amine curing agent is 3,3-dimethyl-4,4-diaminodicyclohexylmethane (DMDC).

[0060] The remaining components of Example 2 ...

Embodiment 3

[0062] An epoxy resin waterproof coating for hydraulic engineering, comprising A component and B component, wherein, 55 parts of hydrogenated bisphenol A epoxy resin, 15 parts of polyurethane modified epoxy resin, 15 parts of epoxy resin toughening agent, 20 parts of diluent, 3 parts of coupling agent, 0.08 part of dispersant No. 1, 0.1 part of carbon black, 0.2 part of defoamer, 5 parts of titanium dioxide, 0.05 part of dispersant No. 2, 5 parts of sericite powder, gas phase dioxide 2 parts of silicon, 0.3 part of antioxidant 1010, 0.3 part of anti-ultraviolet auxiliary UV-327; component B includes the following components by mass: 10 parts of polythiol curing agent, 5 parts of alicyclic amine curing agent part, 0.3 part of accelerator, and 0.3 part of stopper.

[0063] The diluent is chemically resistant reactive diluent K100.

[0064] The remaining components of Example 3 and their preparation method are the same as those of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com