Preparation method of alumina-zirconia ceramic sagger

A technology of zirconia ceramics and alumina, applied in the field of high temperature ceramics, can solve the problems of rough surface, poor bulk density uniformity, loose internal structure, etc., to achieve good alkali corrosion resistance, improve thermal shock stability, and ensure consistency sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The preparation method of alumina-zirconia ceramic sagger, the specific operation steps are as follows:

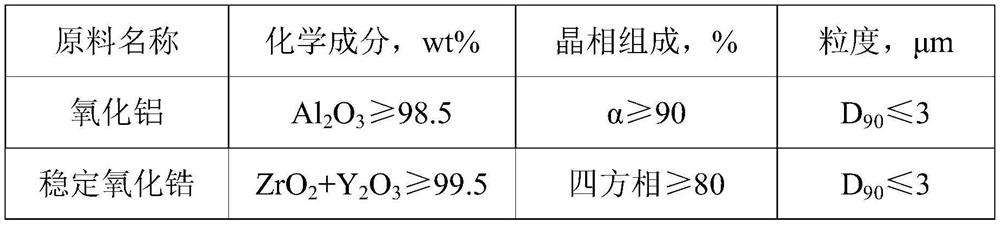

[0027] (1), raw material ratio:

[0028] According to mass percentage, Al 2 o 3 ≥98.5wt% alumina 55-65%, ZrO 2 +Y 2 o 3 ≥99.5wt% stabilized zirconia 15-25%, ZrO 2 ≥99.5wt% monoclinic zirconia 10-15%, additive 10-15%;

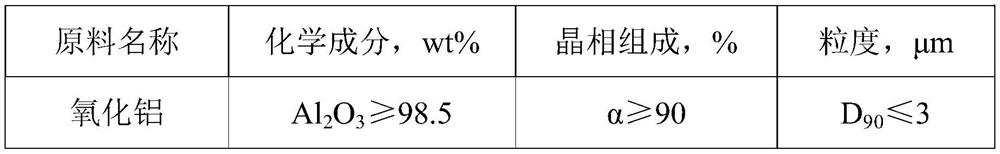

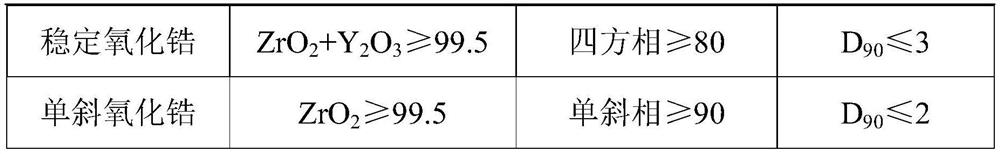

[0029] The crystal phase composition of alumina is α≥90%, and the particle size is D 90 ≤3μm; stable zirconia crystal phase composition of tetragonal phase ≥80%, particle size D 90 ≤3μm; monoclinic zirconia crystal phase composition is monoclinic phase ≥90%, particle size D 90 ≤3μm;

[0030] The additive uses any one of calcium silicate, magnesium silicate, lithium metasilicate or yttrium titanate synthesized by high-purity raw materials through high-temperature calcination; the additive uses high-purity raw materials synthesized by high-temperature calcined calcium silicate, magnesium silicate, Any one of lithium metasilicate or yttrium tit...

Embodiment 1

[0040] The preparation method of alumina-zirconia ceramic sagger, the specific operation steps are as follows:

[0041] Main raw materials and requirements (see the table below):

[0042]

[0043]

[0044] (1), proportioning (mass percentage):

[0045] 55% alumina, 20% stabilized zirconia, 15% monoclinic zirconia, 10% calcium silicate;

[0046] (2), slurry preparation:

[0047] Add the above-mentioned raw materials into a ball mill or a stirring mill according to the proportion, then add 40% of an aqueous solution containing a binder, and mix and mill for 4 hours to make a slurry; the binder is polyvinyl alcohol, and the amount of the binder is 0.4%;

[0048] (3), spray granulation:

[0049] The prepared slurry is made into granulated material through a spray granulator.

[0050] (4), isostatic pressing:

[0051] The granulated material is packed into a rubber mould, and the mold is put into an isostatic press for press molding, and the molding pressure is 120mpa.

...

Embodiment 2

[0055] The preparation method of the alumina-zirconia composite ceramic sagger is characterized in that it comprises the following steps:

[0056] Main raw materials and requirements (see the table below):

[0057]

[0058]

[0059] (1), proportioning (mass percentage):

[0060] 65% alumina, 15% stabilized zirconia, 10% monoclinic zirconia, 10% magnesium silicate;

[0061] (2), slurry preparation:

[0062] Add the above raw materials into a ball mill or a stirring mill according to the proportion, add 50% of an aqueous solution containing a binder, and mix and mill for 5 hours to make a slurry; the binder is pyrrolidone, and the amount of the binder is 0.1%;

[0063] (3), spray granulation: the prepared slurry is made into pellets through a spray granulator;

[0064] (4), isostatic pressing molding: the granulated material is packed in the rubber mould, and mold is put into isostatic pressing machine and pressurized molding, and molding pressure is 140mpa.

[0065] (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com