Method for improving particle size and fluidity of psicose crystal

A technology of allulose and fluidity, which is applied in the field of functional sugar preparation, can solve problems such as unfavorable fluidized bed separation, unsatisfactory crystal shape, and uneven crystal particle size distribution, so as to improve crystal morphology indicators and improve fluidity , weaken the effect of adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

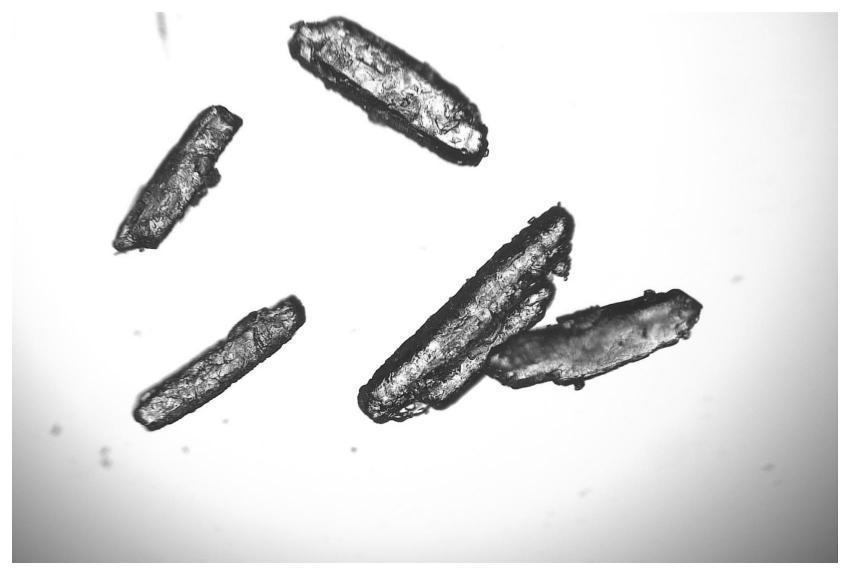

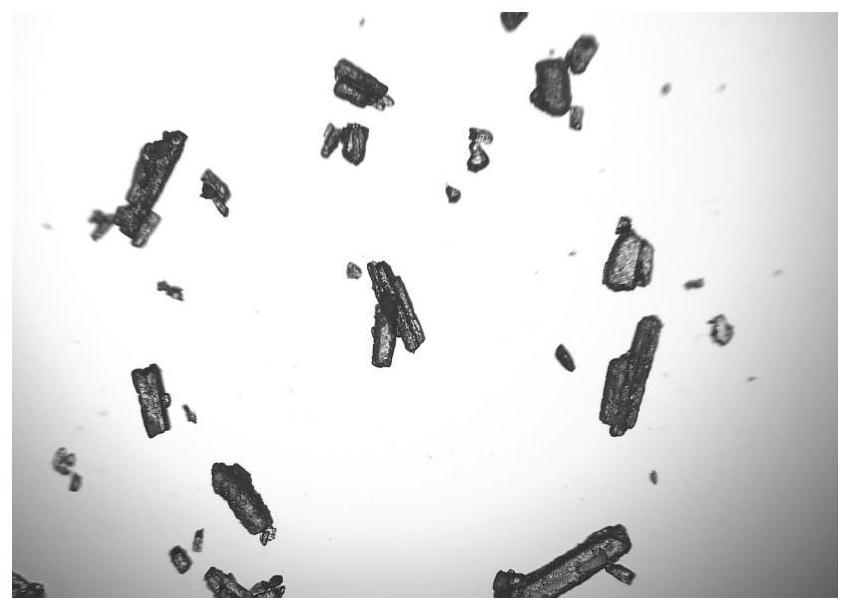

Image

Examples

Embodiment 1

[0030] (1) Add the D-psicose solution concentrated to 60% into the sugar boiling tank and continue to concentrate to 88%, add 2% allulose dry weight, grind, sieve, rinse with ethanol, and sieve again to obtain Seed crystal growth at 48°C for 4 hours;

[0031] (2) Put the D-psicose saturated solution after crystal growth into a crystallizer at 48°C, and lower it to 35°C at a rate of 0.2°C / h;

[0032] (3) The solution obtained in step (2) is subjected to ultrasonic treatment to assist crystallization, the treatment time is 15min, the ultrasonic power is 200w / kg solution, and the frequency is 20kHz;

[0033] (4) The solution obtained in step (3) is returned to temperature, and the temperature of the crystallization solution is raised to 38°C in 60 minutes, and kept at a constant temperature for 2 hours; then it is lowered to 25°C at a rate of 0.4°C / h, and the crystallization is stopped ;

[0034] (5) The product was centrifuged at 1300rpm for 60min, and dried in a fluidized bed...

Embodiment 2

[0039] (1) Add the D-psicose solution concentrated to 65% into the sugar boiling pot and continue to concentrate to 85%, add 1% allulose dry weight, grind, sieve, rinse with ethanol, and sieve again to obtain Seed crystal growth at a constant temperature of 48°C for 5 hours;

[0040] (2) Put the D-psicose saturated solution after crystal growth into a crystallizer at 45°C, and lower it to 30°C at a rate of 0.3°C / h;

[0041] (3) The solution obtained in step (2) is subjected to ultrasonic treatment to assist crystallization, the treatment time is 20min, the ultrasonic power is 200w / kg solution, and the frequency is 20kHz;

[0042] (4) The solution obtained in step (3) is returned to temperature, and the temperature of the crystallization solution is raised to 35°C in 45 minutes, and kept at a constant temperature for 1 hour; then it is lowered to 25°C at a rate of 0.5°C / h, and the crystallization is stopped ;

[0043] (5) The product was centrifuged at 1300rpm for 60min, and ...

Embodiment 3

[0047](1) Add the D-psicose solution concentrated to 70% into the sugar boiling tank and continue to concentrate to 85%, add 0.5% of allulose dry weight, grind, sieve, rinse with ethanol, and sieve again to obtain Seed crystal growth at a constant temperature of 48°C for 5 hours;

[0048] (2) Put the D-psicose saturated solution after crystal growth into a crystallizer at 48°C, and lower it to 35°C at a rate of 0.3°C / h;

[0049] (3) The solution obtained in step (2) is subjected to ultrasonic treatment to assist crystallization, the treatment time is 10min, the ultrasonic power is 200w / kg solution, and the frequency is 20kHz;

[0050] (4) The solution obtained in step (3) is returned to temperature, and the temperature of the crystallization solution is raised to 40°C in 30 minutes, and kept at a constant temperature for 1 hour; then it is lowered to 25°C at a rate of 0.5°C / h, and the crystallization is stopped ;

[0051] (5) The product was centrifuged at 1300rpm for 60min,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com