Sennoside extraction method

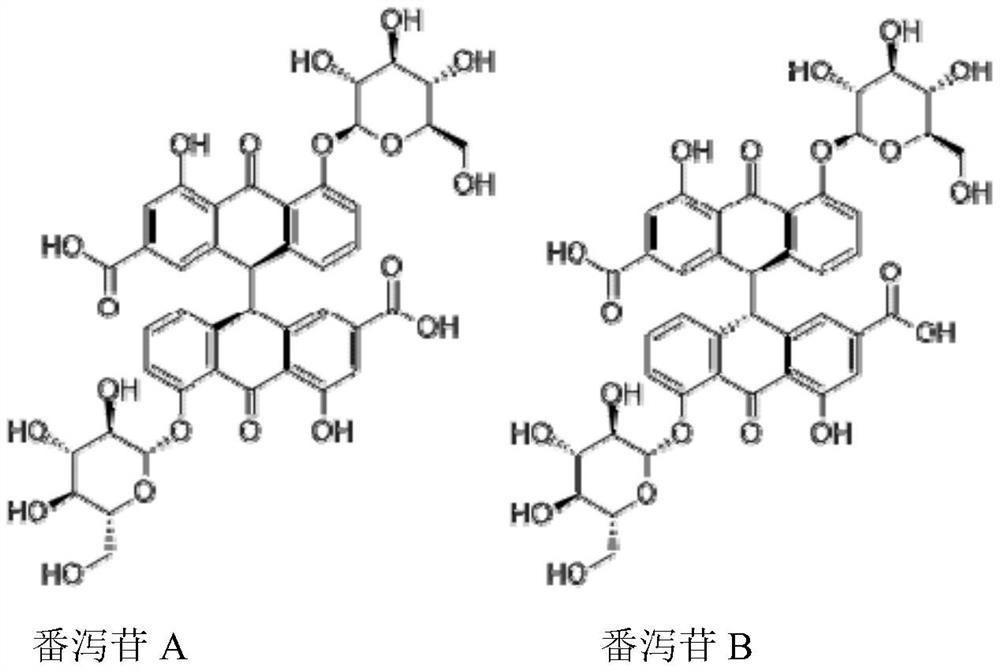

An extraction method and technology of sennoside, applied in the field of sennoside extraction, can solve the problems of poor stability of sennoside, difficult and high-efficiency extraction, easy decomposition and transformation, etc., and achieve convenient separation and purification, low cost, and easy to scale up production. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

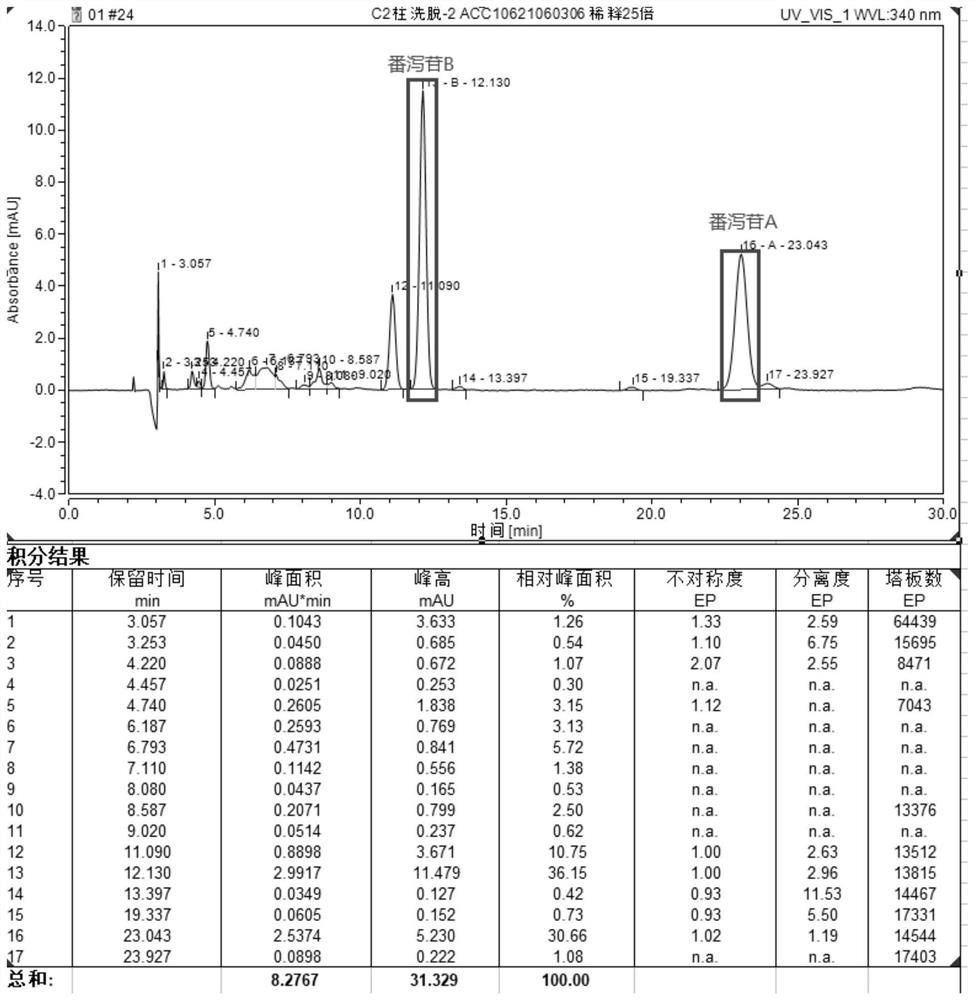

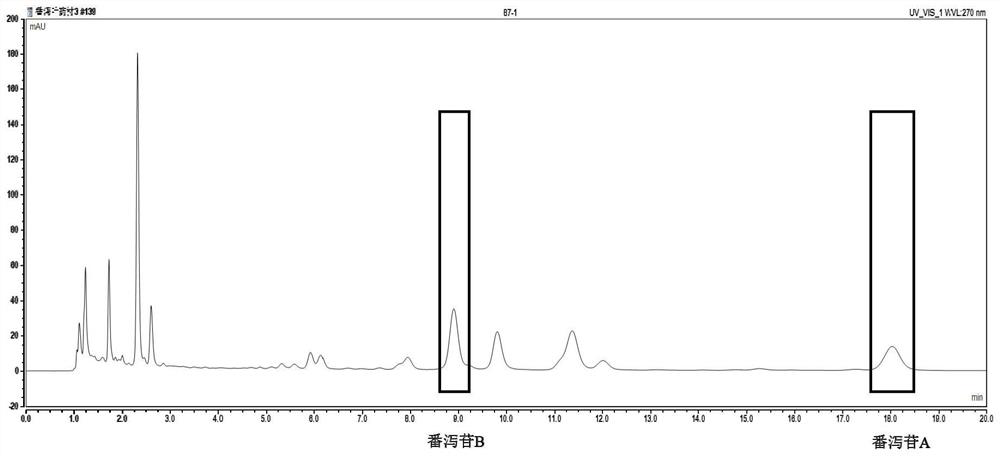

[0025] Embodiment 1: (1) Medicinal material extraction: get 100g senna medicinal material (wherein sennoside A+sennoside B content is 1.25%) add 8 times (g / mL) 0.1% sodium bicarbonate solution stirring extraction 60min after filtering , to obtain the extract (extract sampling test), add 6mol / L HCl to adjust the pH to 3.0, remove impurities, filter and leave the supernatant, add sodium chloride to adjust the electric rate to 20mS / cm, add 5mol / L NaOH to adjust the pH to 3.5, obtain the sample solution (acid adjustment sample solution sampling detection);

[0026] (2) Sample loading: 300 mL of A451 (ZG A451 type, Hangzhou Zhengguang Resin Co., Ltd.) macroporous weakly basic anion-exchange chromatography column is pre-installed, at a linear velocity of 60 cm / h, equilibrated with an equilibrium solution of 5 times the column volume, Equilibrium liquid is 0.02mol / L glycine buffer solution, which contains 0.2mol / L NaCl, pH is 3.5, conductivity is 23mS / cm, and then the sample solution...

Embodiment 2

[0030] Embodiment 2: (1) medicinal material extraction: get 100g senna medicinal material (wherein sennoside A+sennoside B content is 1.23%) add 10 times (g / mL) 0.25% sodium bicarbonate solution and stir to extract 90min after filtering , to obtain the extract (sampling detection), add 6mol / L HCl to adjust the pH to 4.5, filter to leave the supernatant, add sodium chloride to adjust the conductivity to 15mS / cm, add 5mol / LNaOH to adjust the pH to 7.0, and obtain the sample solution ( Acid adjustment sample solution sampling test);

[0031](2) Sample loading: 300mL macroporous weakly basic anion exchange chromatography column of A351 type (ZG A351 type, Hangzhou Zhengguang Resin Co., Ltd.) is pre-installed, and the linear velocity is 60cm / h. Liquid is 0.02mol / L phosphate buffered saline, wherein contains 0.15mol / L NaCl, and pH is 7.0, and conductivity is 18mS / cm, then the sample solution in step (1) is loaded sample layer with linear velocity 60cm / h Analysis column.

[0032] (...

Embodiment 3

[0035] Embodiment 3: (1) medicinal material extraction: get 1000g senna medicinal material (wherein sennoside A+sennoside B content is 1.15%), add 10 times (g / mL) 0.25% sodium bicarbonate solution and stir to extract 120min after filtration , to obtain the extract (extract sample detection), add 6mol / L HCl to adjust the pH to 5.5, filter to leave the supernatant, add sodium chloride to adjust the conductivity to 7mS / cm, add 5mol / L NaOH to adjust the pH to 10.0, and obtain the above Sample solution (acid adjustment sample solution sampling test);

[0036] (2) Sample loading: 1500 ml of A313 type (ZG A313 type, Hangzhou Zhengguang Resin Co., Ltd.) macroporous weakly basic anion exchange chromatography column is pre-installed. It is 0.2mol / L sodium bicarbonate buffer solution, which contains 0.1mol / L NaCl, pH is 10.0, and conductivity is 11mS / cm, and then the sample solution in step (1) is loaded into the sample layer at a linear velocity of 60cm / h Analysis column.

[0037] (3)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com