Plasticizer for biodegradable polyester as well as preparation method and application of plasticizer

A technology for degrading polyesters and plasticizers, which is applied in the preparation of carbamic acid derivatives, the preparation of organic compounds, chemical instruments and methods, etc., can solve the problems of decreased mechanical properties, poor compatibility between plasticizers and polylactic acid, etc. Achieve the effect of improving processing characteristics and toughness, improving compatibility, and improving mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

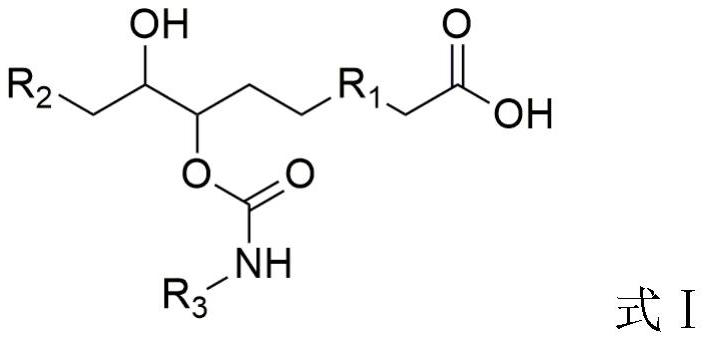

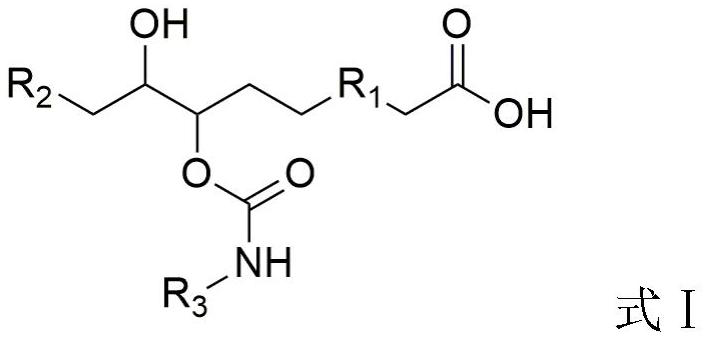

[0034] A plasticizer for biodegradable polyester provided in this embodiment contains a vegetable oil-based compound of the following structural formula:

[0035]

[0036] The preparation method of the biodegradable polyester plasticizer of the present embodiment is as follows:

[0037] S1. Place 100g oleic acid, 5g formic acid, 5g hydrogen peroxide and 80mL petroleum ether in a dry 500mL reactor, react at 50°C for 8h, then separate the solvent, extract the crude product with water and dichloromethane, and extract the organic The dichloromethane in the phase was removed to obtain epoxy oleic acid.

[0038] S2. Add 60g of epoxy oleic acid, 1g of tetrabutylammonium bromide, and 60mL of toluene to a 200mL autoclave that has been dried in an oven at 60°C for 2 hours, seal the autoclave and add CO 2 Pressurize to 2.0MPa; place the reaction vessel at 70°C for 10 hours; after the reaction, cool the reaction vessel to room temperature and slowly release the CO 2 , after removing ...

Embodiment 2

[0044] A plasticizer for biodegradable polyester provided in this embodiment contains a vegetable oil-based compound of the following structural formula:

[0045]

[0046] The preparation method of the biodegradable polyester plasticizer of the present embodiment is as follows:

[0047] S1. Place 100g oleic acid, 5g formic acid, 5g hydrogen peroxide and 80mL petroleum ether in a dry 500mL reactor, react at 50°C for 8h, then separate the solvent, extract the crude product with water and dichloromethane, and take the organic phase, the dichloromethane in the organic phase was removed to obtain epoxy oleic acid.

[0048] S2. Add 60g of epoxy oleic acid, 5g of tetrabutylphosphine bromide, and 60mL of toluene to a 200mL autoclave that has been dried in an oven at 60°C for 2 hours, seal the autoclave and add CO 2 Pressurize to 4.0MPa; place the reactor in a constant temperature oil bath at 100°C, and react for 10 hours; after the reaction, cool the reactor to room temperature, s...

Embodiment 3

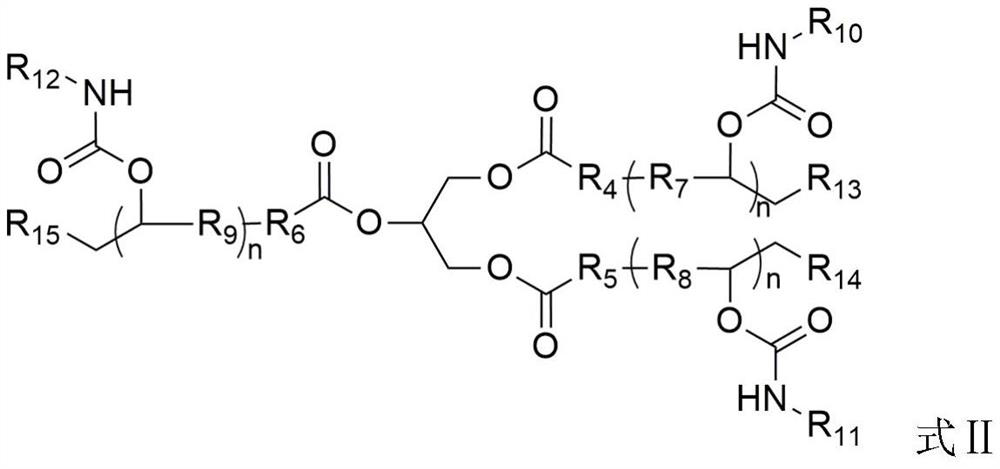

[0054] A plasticizer for biodegradable polyester provided in this embodiment contains a vegetable oil-based compound of the following structural formula:

[0055]

[0056] The preparation method of the biodegradable polyester plasticizer of the present embodiment is as follows:

[0057] S1. Place 100g soybean oil, 5g formic acid, 40g hydrogen peroxide and 80mL n-hexane in a dry 500mL reactor, react at 60°C for 8h, then separate the solvent, extract the crude product with water and dichloromethane, and extract the organic The dichloromethane in the phase was removed to obtain epoxidized soybean oil.

[0058] S2. Add 60g of epoxidized soybean oil, 10g of tetrabutylammonium bromide, and 80mL of tetrahydrofuran to a 250mL autoclave that has been dried in an oven at 60°C for 2 hours in advance, seal the autoclave and add CO 2 Pressurize to 6.0MPa; place the reactor in a constant temperature oil bath at 120°C, and react for 24 hours; after the reaction, cool the reactor to room ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com