Cross-linking agent for reconstructed wellbore fracturing as well as preparation method and application of cross-linking agent

A cross-linking agent and fracturing technology, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of small perforation hole diameter, large leakage, and difficulty in adding sand to reduce guanidine Glue use concentration, reduce the use concentration, reduce the effect of residue content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] 1. Preparation of cross-linking agent

[0044] (1) In a three-neck flask equipped with a stirrer, a reflux condenser and a constant pressure dropping funnel, add 100ml of water and 15ml of ethylene glycol, and stir evenly to obtain the first mixture.

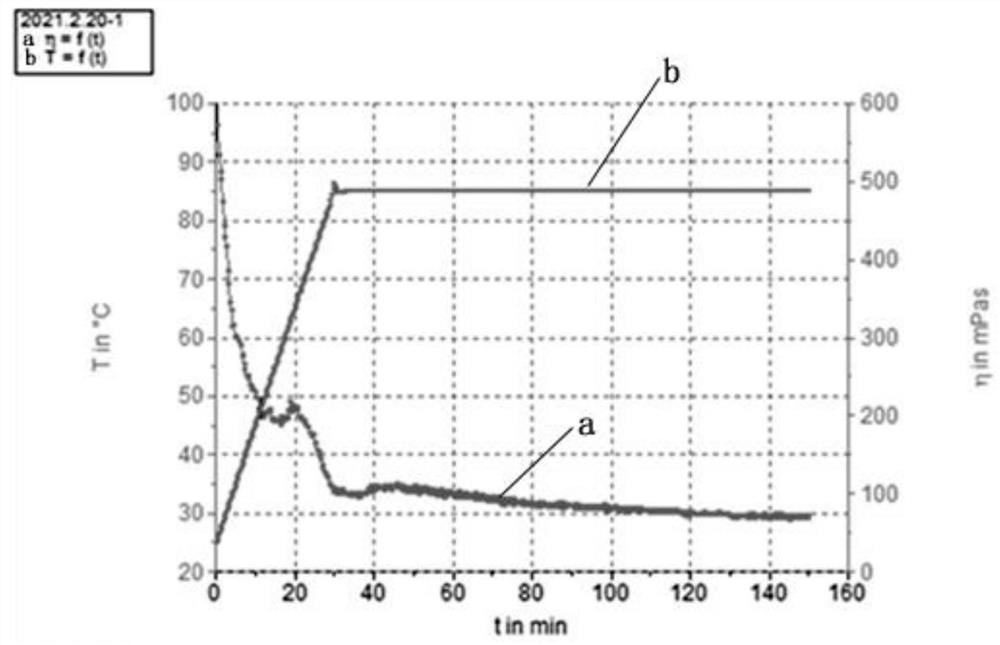

[0045] (2) Heat the first mixture to 40° C. in a water bath, adjust the rotation speed to 100 r / min, add 15 g of boric acid and 20 ml of 15% sodium carbonate solution with stirring, and stir for 3 hours to obtain the second mixture.

[0046] (3) After the second mixture was stirred evenly, the temperature was raised to 80° C., the rotational speed was adjusted to 200 r / min, 20 g of sodium gluconate was added, and after stirring for 3 hours, it was cooled to room temperature to obtain a transparent liquid as a crosslinking agent.

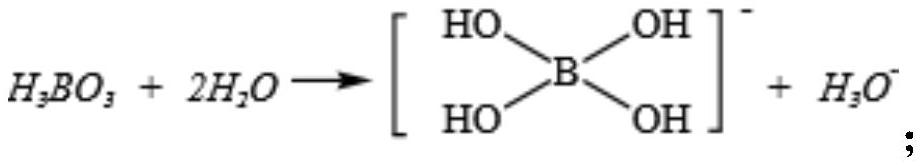

[0047] In the above preparation method, the polyol is ethylene glycol, boric acid is used as the boron compound to provide borate ions, the alkali solution is 15% sodium carbonate solution, and ...

Embodiment 2

[0055] 1. Preparation of cross-linking agent

[0056] (1) In a three-neck flask equipped with a stirrer, a reflux condenser and a constant pressure dropping funnel, add 100ml of water and 20ml of glycerol, and stir evenly to obtain the first mixture.

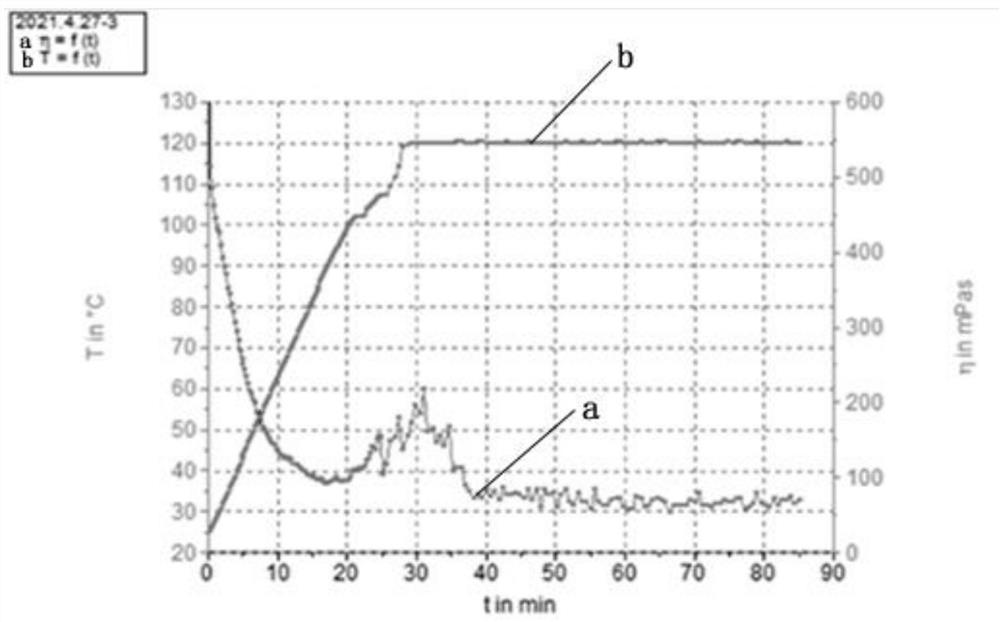

[0057] (2) Heat the first mixture to 45°C in a water bath, adjust the rotation speed to 120r / min, add 20g of sodium tetraborate and 15ml of sodium hydroxide solution with a mass fraction of 10% under stirring conditions, and stir for 3h to obtain the first Two mixtures.

[0058] (3) After the second mixture was stirred evenly, the temperature was raised to 80° C., the rotational speed was adjusted to 200 r / min, 20 g of triethanolamine was added, stirred for 3 hours, and then cooled to room temperature to obtain a transparent liquid as a crosslinking agent.

[0059] In the above preparation method, the polyol is glycerol, the boron compound uses borax to provide borate ions; the alkali solution is 10% sodium hydroxide solution, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com