Electron transport ink, electron transport film, electroluminescent diode and display device

An electron transport and electron transport material technology, applied in the field of electronic display, can solve the problems of device leakage current, poor electron transport layer performance, and quantum dot light-emitting diode luminous performance and life performance decline.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

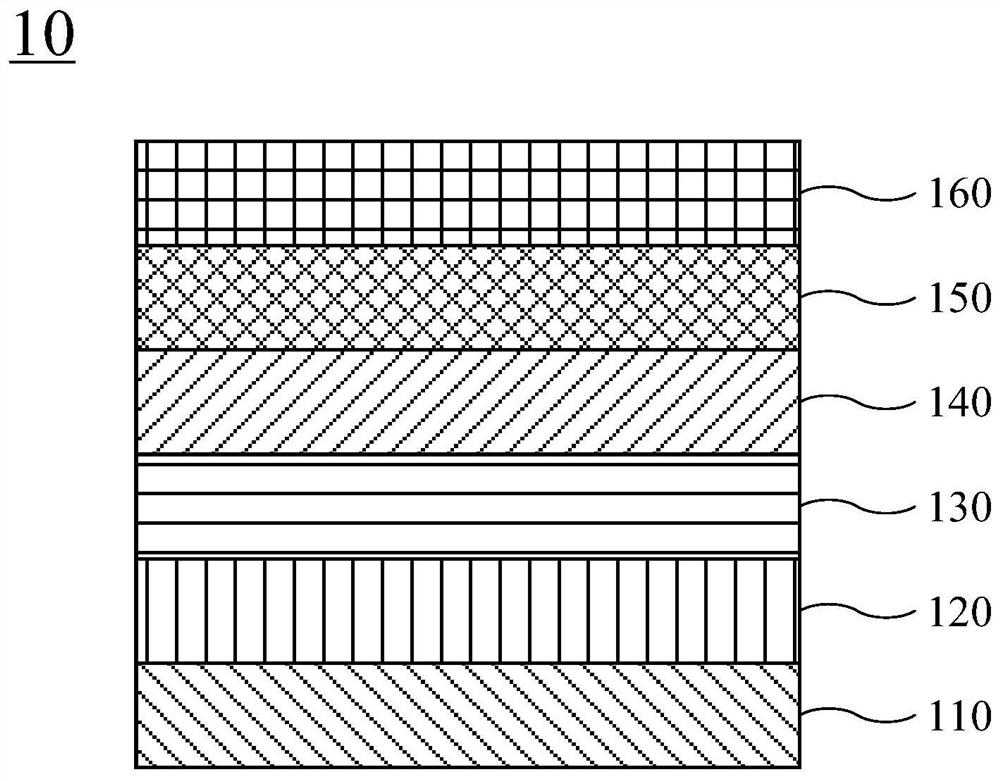

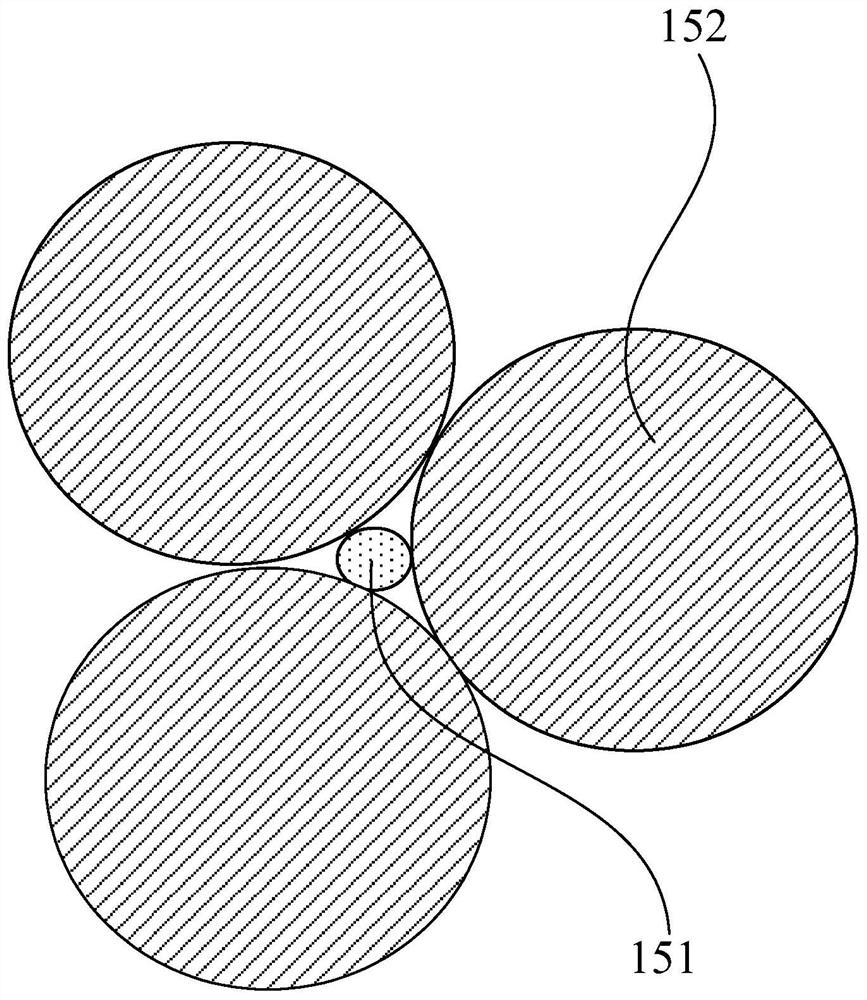

[0050] In the electroluminescent diode 10, the electron transport layer 150 is a thin film formed by stacking two types of nanoparticles with different particle sizes. The thin film may be formed by removing the dispersant in the ink including the two kinds of nanoparticles with different particle sizes after being formed on the surface of the light-emitting layer 140 . Specifically, the preparation method of the electron transport layer may include the following steps:

[0051] The ink is formed on the base material by a solution method, and then the dispersant in the ink is removed by heating and drying, and at the same time, the nano-material thin film is annealed. Annealing treatment can reduce the overall free energy of the film to a certain extent, reconstruct the crystal structure of the nanomaterials, eliminate some defects in the nanomaterials, and make the nanomaterials bond more closely, improving the electrical properties of the film.

[0052] Among them, the solu...

Embodiment 1

[0070] Under stirring, 1 g of ZnO spherical nanoparticles with a particle size of about 20 nm, 0.01 g of ZnO spherical nanoparticles with a particle size of about 3 nm, 50 g of glycerol, and 10 g of isopropanol solvent were added to a 100 mL round bottom flask. , and continue to stir the mixture for 30 minutes to make it disperse uniformly without coagulation to obtain ZnO ink.

Embodiment 2

[0072] Under stirring, 1 g of ZnMgO spherical nanoparticles with a particle size of about 30 nm, 0.02 g of ZnMgO nanoparticles with a particle size of about 4 nm, 50 g of glycerol, and 10 g of isopropanol solvent were added to a 100 mL round-bottomed flask in turn, The mixture was continued to be stirred for 30 minutes to make it dispersed uniformly without coagulation to obtain ZnMgO ink.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com