NiMo6-S-@HCS nanocomposite material and preparation method thereof, and application of NiMo6-S-@HCS nanocomposite material in electro-catalytic hydrogen production

A nano-composite material and nano-material technology are applied in the field of transition metal sulfide electrode materials and their preparation, which can solve the problem of high overpotential and achieve the effects of increasing kinetic rate, improving catalytic performance and excellent electrochemical activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Example 1. Preparation of hollow carbon spheres

[0067] To a solution containing 70 mL of ethanol, 10 mL of deionized water and 3 mL of ammonia solution (25 wt%) was added 3.46 mL of ethyl orthosilicate with vigorous stirring at room temperature. After stirring for 15 minutes, 0.4 g of resorcinol and 0.56 mL of formaldehyde solution (37 wt %) were added to the solution, and the mixed solution was vigorously stirred at room temperature for 24 hours. The precipitate was isolated by centrifugation, washed with deionized water and ethanol, and then dried under vacuum at 60°C overnight. Precipitate in N 2 700°C (2°C min -1 ) for 5 hours to obtain SiO 2 @SiO 2 / C Nanospheres. Finally, the silica was removed by etching with sodium hydroxide (NaOH, 1.5M) for 48 hours to obtain hollow carbon spheres.

Embodiment 2

[0068] Embodiment 2, NiMo 6 - Preparation of S@HCS-10 nanocomposites

[0069] (1) 5.19g ammonium heptamolybdate tetrahydrate ((NH 4 ) 6 Mo 7 O 24 ·4H 2 O) was dissolved in 80 mL of deionized water, then heated to 100°C. 1.16g nickel nitrate hexahydrate (Ni(NO 3 ) 2 ·6H 2 O) was dissolved in 20 mL of deionized water and added to the above solution with stirring. The mixture was heated and stirred continuously to produce a dark green solution. The crude product was isolated by evaporation and filtration, recrystallized twice in hot water at 80 °C, and then dried under vacuum to obtain the green target product NiMo 6 .

[0070] (2) 0.2g NiMo 6 Dissolve in 32 mL of deionized water, then add 0.228 g of thiourea. After stirring for 20 minutes, 10 mg of hollow carbon spheres were added, followed by sonication for 1 hour, and the solution was transferred to a polytetrafluoroethylene autoclave (50 mL) for hydrothermal reaction at 200° C. for 48 hours. The product was wash...

Embodiment 3

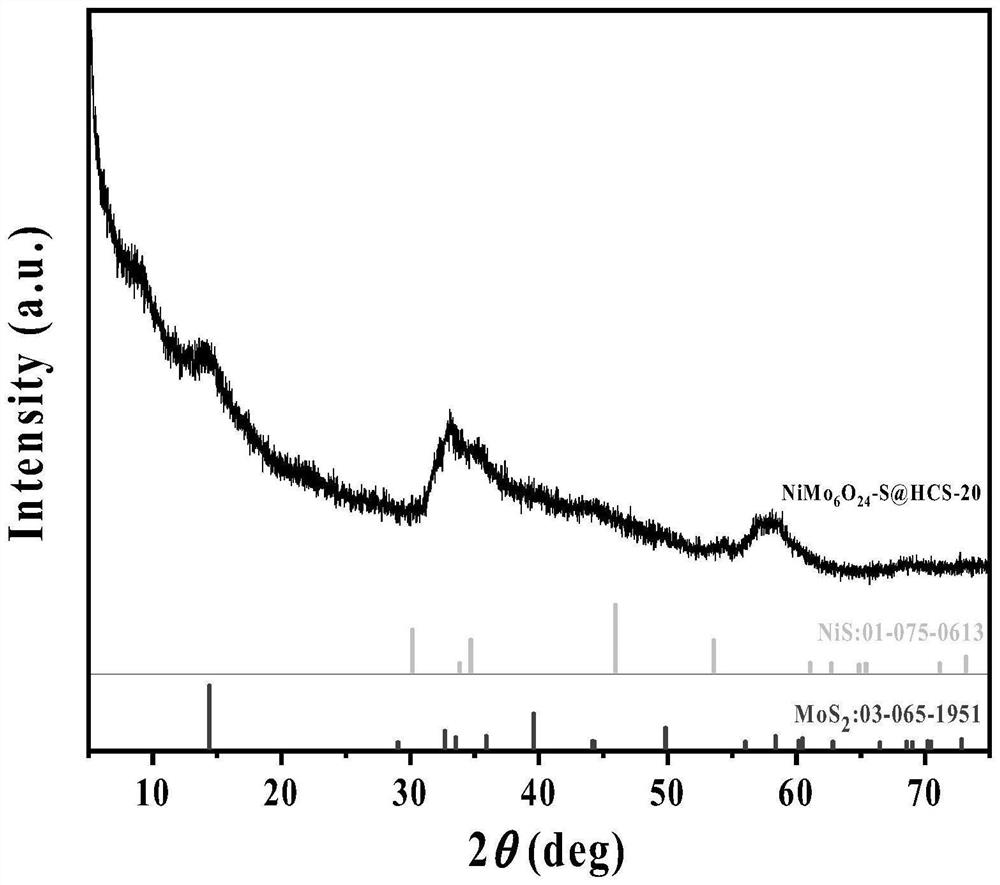

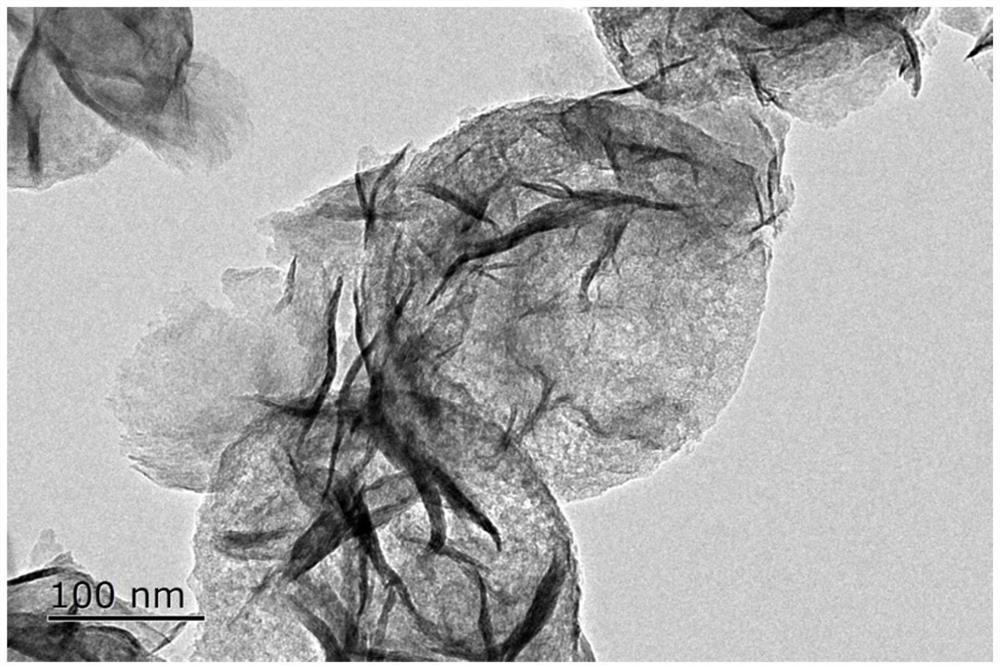

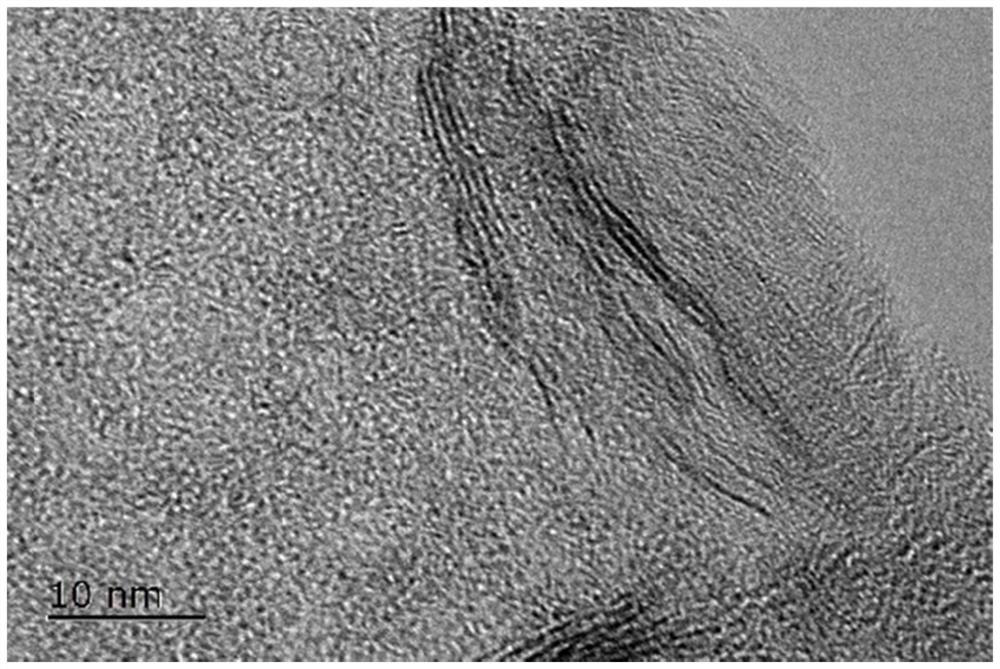

[0071] Embodiment 3, NiMo 6 - Preparation of S@HCS-20 nanocomposites

[0072] (1) 5.19g ammonium heptamolybdate tetrahydrate ((NH 4 ) 6Mo 7 O 24 ·4H 2 O) was dissolved in 80 mL of deionized water, then heated to 100°C. 1.16g nickel nitrate hexahydrate (Ni(NO 3 ) 2 ·6H 2 O) was dissolved in 20 mL of deionized water and added to the above solution with stirring. The mixture was heated and stirred continuously to produce a dark green solution. The crude product was isolated by evaporation and filtration, recrystallized twice in hot water at 80 °C, and then dried under vacuum to obtain the green target product NiMo 6 .

[0073] (2) 0.2g NiMo 6 Dissolve in 32 mL of deionized water, then add 0.228 g of thiourea. After stirring for 20 minutes, 20 mg of hollow carbon spheres were added, followed by sonication for 1 hour, and the solution was transferred to a polytetrafluoroethylene autoclave (50 mL) for hydrothermal reaction at 200° C. for 48 hours. The product was washe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com