Inorganic/polymer composite lithium ion sieve membrane as well as preparation method and application thereof

A polymer film and polymer technology, applied in structural parts, electrochemical generators, electrolytes, etc., can solve the problems of increasing process complexity, difficulty in large-scale production, and reducing electrical conductivity, etc., to achieve low cost and high selectivity , good flexibility and mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

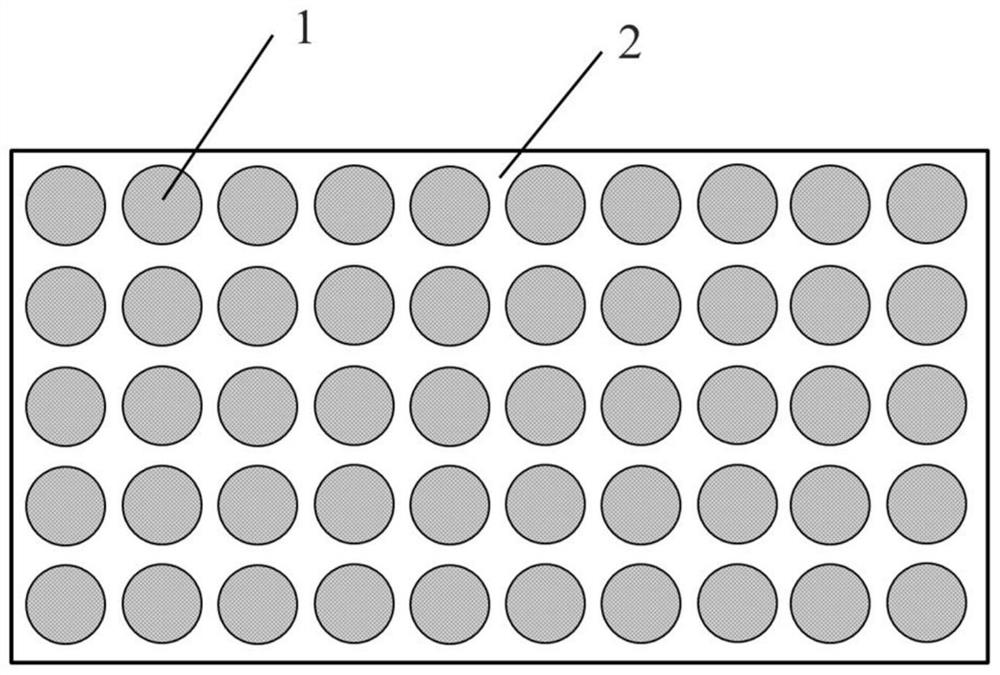

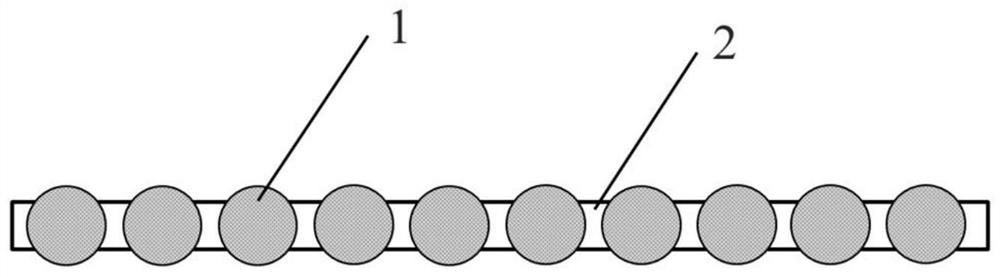

[0046] This embodiment provides a method for preparing a composite lithium ion sieve membrane with a high content of inorganic particles, comprising the following steps:

[0047] 1. Weigh Li according to the mass ratio of 0.74g:0.305g:1.878g:4.128g 2 CO 3 , Al 2 o 3 , GeO 2 and NH 4 h 2 PO 4 Precursor, mixed by ball milling, the ratio of ball to material is 4:1, the speed is 400rpm, every 20 minutes of ball milling, stand still for 5 minutes, cycle 20 times; then heat treat the precursor, raise the temperature to 600 ℃ at 2 ℃ / min, keep it warm for 1 hour and then cool naturally; Next, the heat-treated precursor was ball-milled again, the ball-to-material ratio was 4:1, and the rotation speed was 400 rpm. Every 20 minutes of ball milling, it was left to stand for 5 minutes, and the cycle was repeated 20 times.

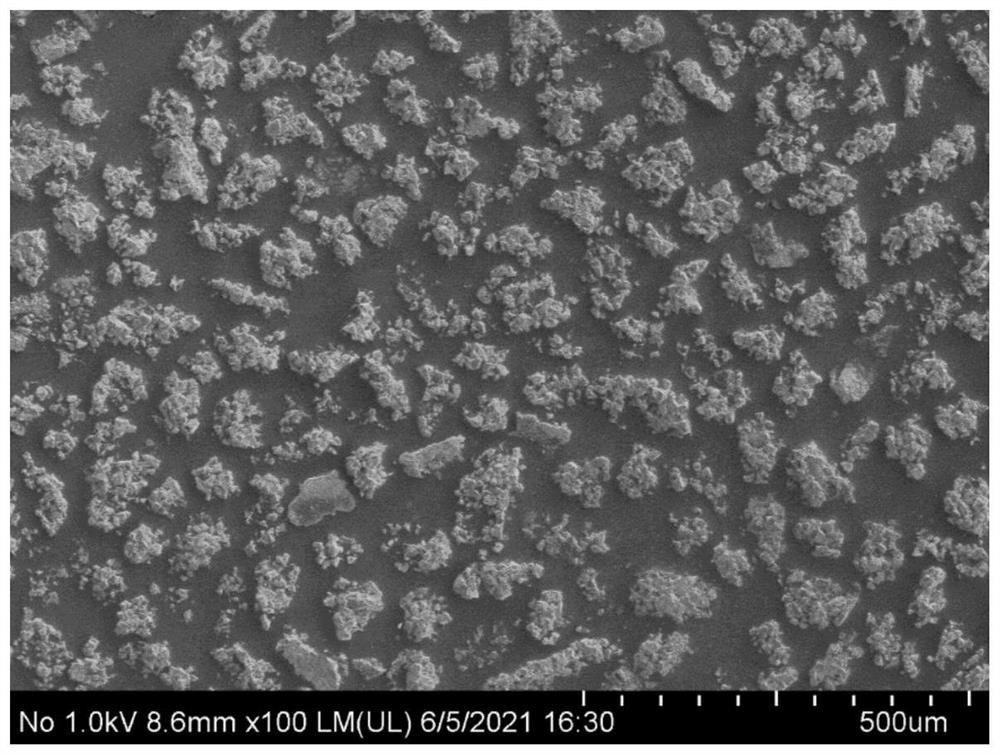

[0048] 2. The precursor powder after ball milling was heated up to 900°C at a heating rate of 2°C / min for sintering, kept for 6 hours and cooled naturally to obt...

Embodiment 2

[0053] The preparation method of the LAGP-PE composite lithium ion sieve membrane in this example is the same as that in Example 1, except that the thickness of the PE membrane is 30 μm.

[0054] At room temperature, test the electrochemical impedance of the LAGP-PE composite lithium ion sieve membrane in this embodiment, the test results are as follows Figure 5 (a) shown. It is calculated that the ion conductivity of the LAGP-PE composite lithium ion sieve membrane in this example can reach 3.0*10 -5 S / cm, which basically meets the requirements of electrolyte conductivity for lithium batteries operating at room temperature.

[0055] Figure 5 (b) is an Arrhenius curve of the ion conductivity of the LAGP-PE composite lithium ion sieve membrane based on the present embodiment as a function of temperature. It can be seen from the graph that the ionic conductivity and temperature of the LAGP-PE composite ion sieve membrane satisfy the Arrhenius linear relationship, which is t...

Embodiment 3

[0057] The preparation method of the LAGP-PE composite lithium ion sieve membrane in this example is the same as that in Example 1, the only difference being that the particle size range of the LAGP electrolyte particles is 42.4-49.4 μm.

[0058] Seal the white anhydrous copper sulfate in the test tube with LAGP-PE composite lithium ion sieve membrane, then immerse it in water, and observe the color change of the anhydrous copper sulfate regularly. Anhydrous copper sulfate gradually turned blue after 120 hours, indicating that the LAGP-PE composite lithium ion sieve membrane has good sealing performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com