Genetically engineered bacterium with high yield of squalene, construction method and application thereof

A technology of genetically engineered bacteria and construction methods, applied in the field of high-yield squalene genetically engineered bacteria and its construction, to achieve efficient transformation and integration, shorten the construction cycle, and increase production

- Summary

- Abstract

- Description

- Claims

- Application Information

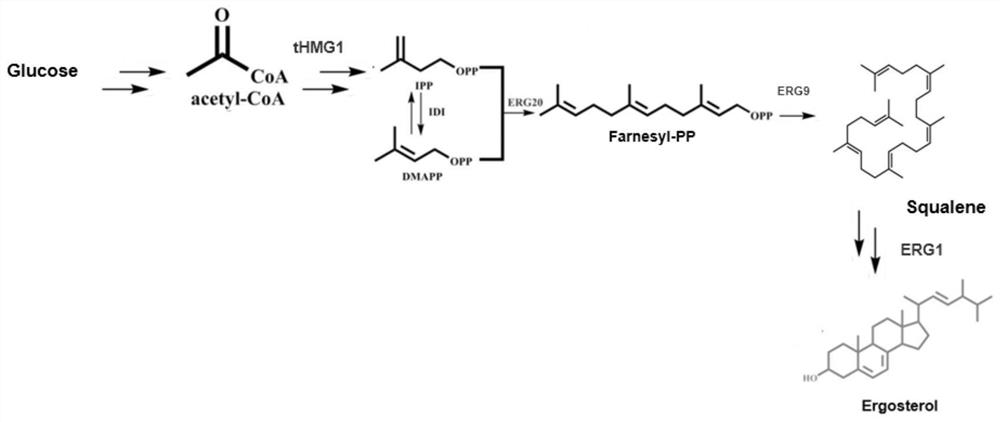

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

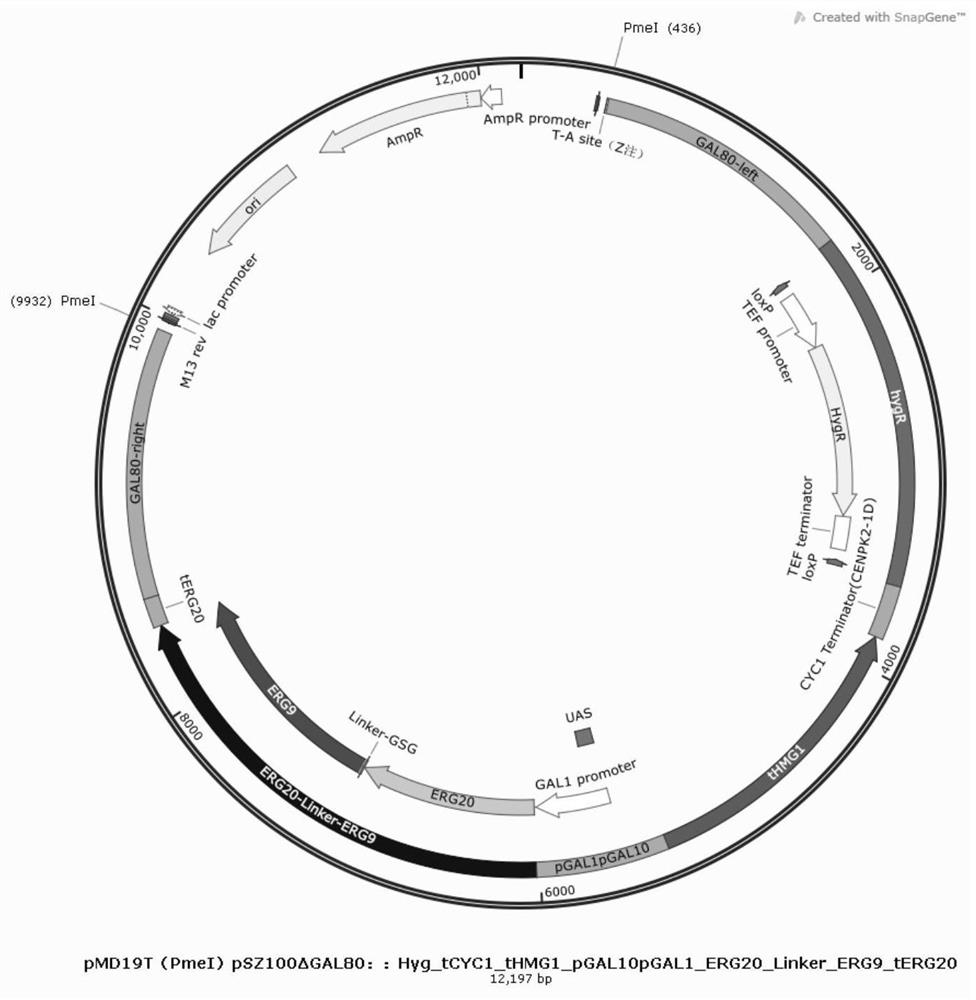

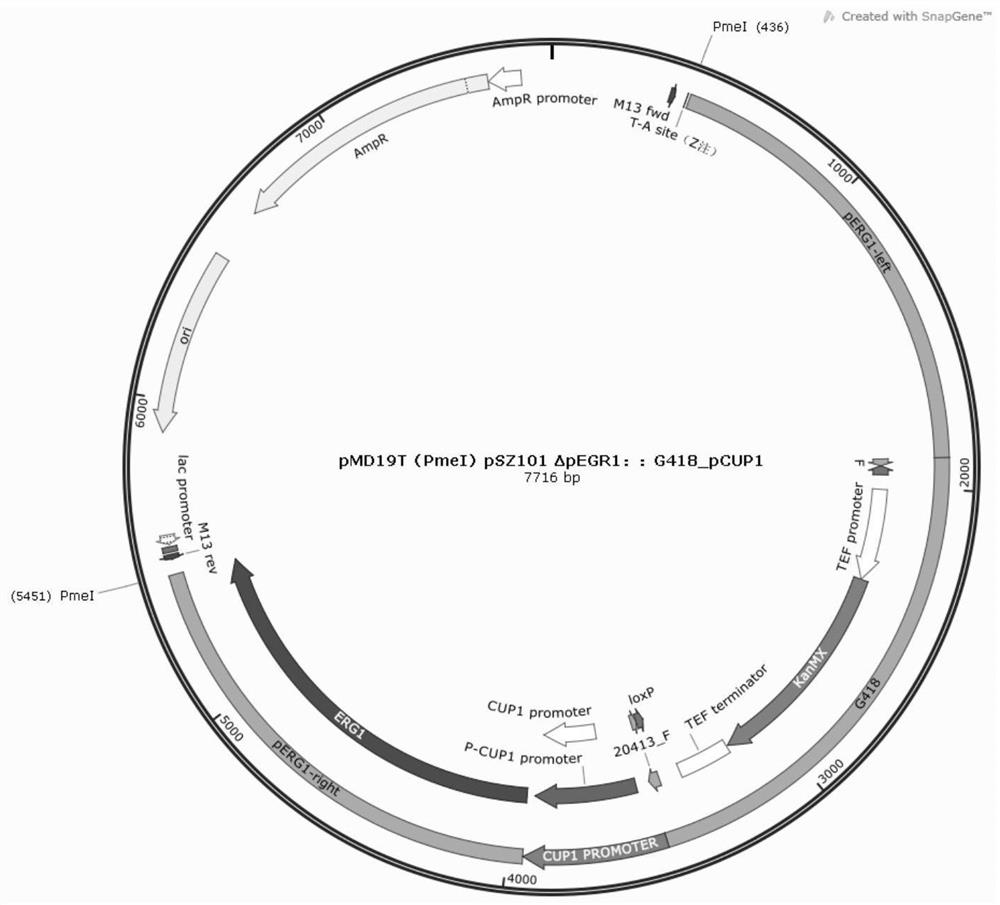

[0063] Construction of high-yield squalene genetically engineered strain GS-A3-S4:

[0064] Step S1, construction of overexpressed tHMG1 module

[0065] tCYC1_tHMG1_pGAL10pGAL1

[0066] 1) Using Saccharomyces cerevisiae 3000B genomic DNA as a template, PCR reactions were performed with primers tCYC1-F and tCYC1-R, tHMG1-F and tHMG1-R, pGAL1pGAL10-F and pGAL1pGAL10-R, respectively, to obtain DNA fragments tCYC1, tHMG1 and pGAL10pGAL1;

[0067] 2) The three DNA fragments tCYC1, tHMG1 and pGAL10pGAL1 obtained in step S1 were connected together by overlapping extension PCR reaction with primers tCYC1-F and pGAL1pGAL10-R to obtain the overexpressed tHMG1 module, namely the tCYC1_tHMG1_pGAL10pGAL1 module.

[0068] Step S2, construction of fusion expression ERG20-Linker-ERG9 module

[0069] ERG20_Linker_ERG9_tERG20

[0070] 1) Using Saccharomyces cerevisiae 3000B genomic DNA as a template, PCR reactions were performed with ERG20-F and ERG20-Linker-S-R primers respectively, and the...

Embodiment 2

[0093] Construction of genetically engineered bacteria GS-A3-S5:

[0094] The construction method is the same as in Example 1, wherein the Linker selected in step S3 is connected to Linker2, and the constructed DNA fragment for knocking out the expression of the galactose regulatory protein GAL80 gene is:

[0095] GAL80left_Hyg_tCYC1_tHMG1_pGAL10pGAL1_ERG20_Linker2_ERG9_tERG20_GAL80right;

[0096] The constructed recombinant plasmid vector pSZ200 is:

[0097] pCZ200ΔGAL80::Hyg_tCYC1_tHMG1_pGAL10pGAL1_ERG20_Linker2_ERG9_tERG20;

[0098] The constructed engineered bacteria for knocking out the expression of the galactose regulatory protein GAL80 gene is GS-A3-S2.

Embodiment 3

[0100] Construction of genetically engineered bacteria GS-A3-S6:

[0101] The construction method is the same as in Example 1, wherein the Linker selected in step S3 is Linker3, and the constructed DNA fragment for knocking out the expression of the galactose regulatory protein GAL80 gene is:

[0102] GAL80left_Hyg_tCYC1_tHMG1_pGAL10pGAL1_ERG20_Linker3_ERG9_tERG20_GAL80right;

[0103] The constructed recombinant plasmid vector pSZ300 is:

[0104] pCZ300ΔGAL80::Hyg_tCYC1_tHMG1_pGAL10pGAL1_ERG20_Linker3_ERG9_tERG20;

[0105] The engineered bacteria for knocking out the expression of the galactose regulatory protein GAL80 gene is GS-A3-S3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com