Copper-based amorphous brazing filler metal and preparation method thereof

An amorphous, copper-based technology, applied in the direction of manufacturing tools, welding equipment, metal processing equipment, etc., can solve the problems of brazing material brittleness at room temperature, limited application range, poor processability, etc., achieve narrow melting temperature range, and reduce processing procedures , easy processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

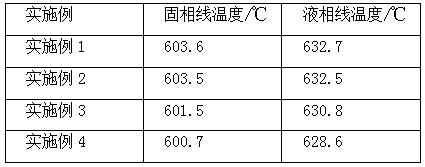

Examples

Embodiment 1

[0025] The copper-based amorphous solder preparation method of the present embodiment comprises the following steps:

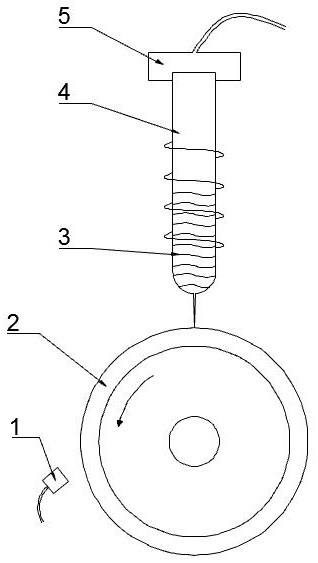

[0026] The composition and content of alloying elements are: P: 6.5%, Sn: 9.5%, Ni: 5%, Cu: balance. Alloy smelting: Use intermediate frequency furnace for alloy smelting and casting into CuPSnNi alloy ingot. Put the ingot of the above-mentioned suitable length into the installed and debugged quartz crucible 4, the inert gas blowing device 5 will vacuum the quartz crucible 4, start and adjust the power of the quartz crucible 4 (for high-frequency remelting, the power of the quartz crucible 4 It should be increased gradually, such as continuous increase with roughly the same power increase rate, or a step-like increase in power for a certain amount of increase, such as 1kw, for several minutes, a special case of step-like increase in power, the same below); when the surface of the alloy ingot is heated and turns red, it can be appropriate Speed up the power ...

Embodiment 2

[0028] The copper-based amorphous solder preparation method of the present embodiment comprises the following steps:

[0029] The composition and content of alloying elements are: P: 6.5%, Sn: 9.7%, Ni: 5.5%, Cu: balance. Alloying and smelting is carried out in an intermediate frequency furnace, and cast into CuPSnNi alloy ingots. Put the ingot of the above-mentioned suitable length into the quartz crucible 4 that has been installed and adjusted, the inert gas blowing device 5 will vacuum the quartz crucible 4, start and adjust the power of the quartz crucible 4, and turn on when the surface of the ingot starts to heat and turn red Cooling roller 2, and finally control the temperature in the quartz crucible 4 between 750°C and 850°C; when the ingot is completely melted and the alloy melt 3 drips from the bottom of the quartz crucible 4, turn on the compressed air blowing device 1 in front of the cooling roller 2 , slowly lower the height of the quartz crucible 4, and at the s...

Embodiment 3

[0031] The copper-based amorphous solder preparation method of the present embodiment comprises the following steps:

[0032] The composition and content of alloying elements are: P: 6.5%, Sn: 9.7%, Ni: 5.5%, Si: 0.02%, Cu: balance. Alloying and smelting is carried out in an intermediate frequency furnace, and cast into CuPSnNi(Si) alloy ingots. Put the ingot of the above-mentioned suitable length into the quartz crucible 4 that has been installed and adjusted, the inert gas blowing device 5 will vacuum the quartz crucible 4, start and adjust the power of the quartz crucible 4, and turn on when the surface of the ingot starts to heat and turn red Cooling roller 2, and finally control the temperature in the quartz crucible 4 between 750°C and 850°C; when the ingot is completely melted and the alloy melt 3 drips from the bottom of the quartz crucible 4, turn on the compressed air blowing device 1 in front of the cooling roller 2 , slowly lower the height of the quartz crucible ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com