Method for detecting formaldehyde carbonylation reaction product by high performance liquid chromatography

A technology of high-performance liquid chromatography and carbonylation reaction, which is applied in the field of analytical chemistry, can solve the problems of gas chromatography, such as difficult gasification, low response value, and difficult analysis, and achieve the effects of small analysis error, high precision, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A method for detecting formaldehyde carbonylation reaction products by high performance liquid chromatography, comprising the following steps:

[0035] (1) Preparation of liquid chromatography mobile phase:

[0036] Take methanol or acetonitrile, filter through an organic membrane, and use ultrasonic treatment for 10-30 minutes as the organic phase; take ultrapure water, filter with an aqueous membrane filter, and use ultrasonic treatment for 10-30 minutes as the aqueous phase;

[0037] (2) Preparation of mixed standard stock solution:

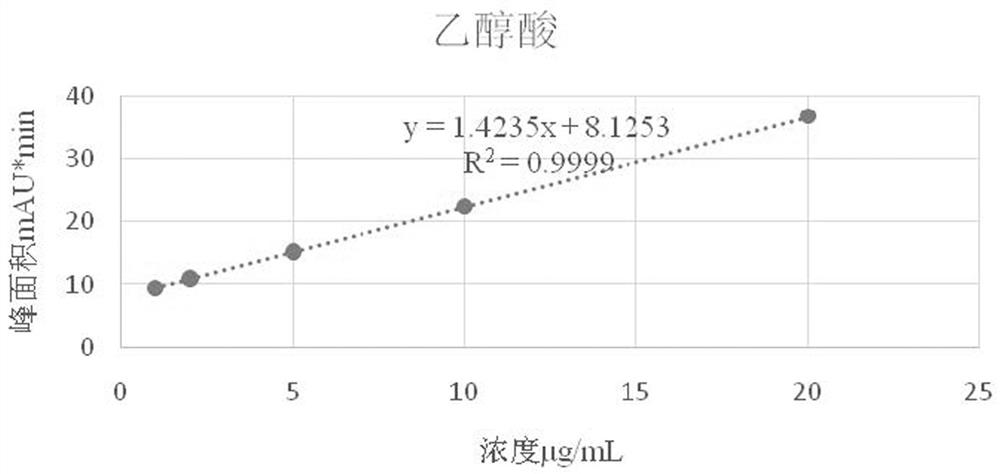

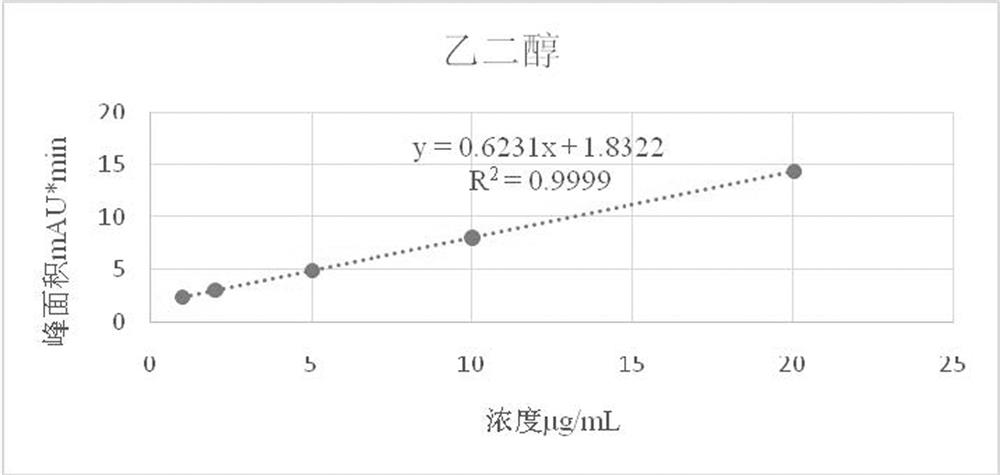

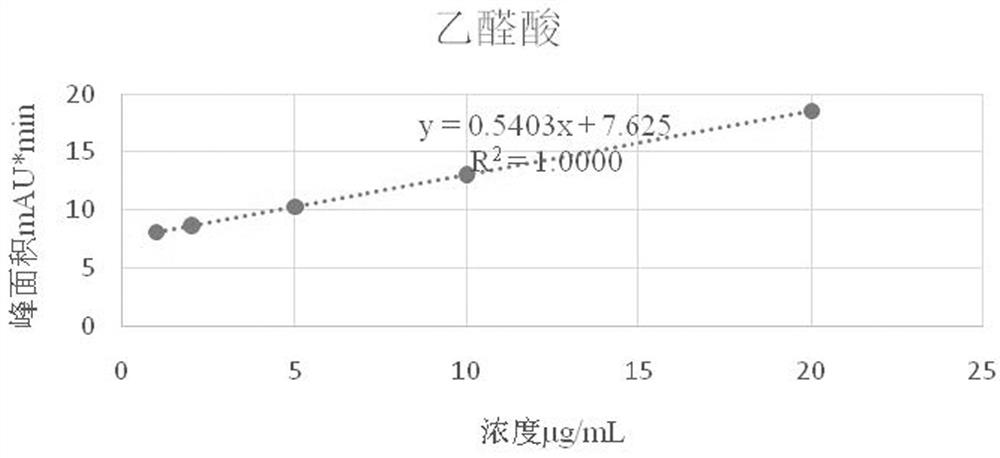

[0038] Weigh glycolic acid, ethylene glycol, glyoxylic acid aqueous solution, acetic acid, acetaldehyde and formaldehyde aqueous solution in volumetric flasks respectively, use organic solvent to constant volume, shake up 1-2min, obtain mixed standard stock solution; In the solution, the concentration of each component is as follows: glycolic acid 10-200μg / mL, ethylene glycol 10-200μg / mL, glyoxylic acid 5-200μg / mL, acetic acid 10-200μg...

Embodiment 2

[0049] On the basis of Example 1, the chromatographic conditions are established as follows:

[0050] The chromatographic column is one of C18 chromatographic column, porous silica gel chromatographic column, and C8 chromatographic column; the diameter of the chromatographic column is 1-5mm, the length is 10-50mm, and the particle size is 1-5μm; the elution method is isocratic elution; in the mobile phase The proportion of the organic phase is 30%-70%, and the rest is the aqueous phase; the temperature of the column oven is 10-50°C; the flow rate is 0.5-5mL / min; the injection volume is 5-20μL; the detection is an ultraviolet detector with a wavelength of 200-400nm.

[0051] The concentration of the glyoxylic acid aqueous solution is 50wt%, and the concentration of the formaldehyde aqueous solution is 40wt%.

[0052] Preferably, the organic membrane is a 0.22 μm nylon filter membrane or a 0.22 μm PTFE filter membrane, and the water-based filter membrane is a 0.22 μm MCE filter...

Embodiment 3

[0054] A method for detecting formaldehyde carbonylation reaction products by high performance liquid chromatography, comprising the following steps:

[0055] (1) Preparation of liquid chromatography mobile phase:

[0056] Take 500mL of methanol, filter with a 0.22μm nylon filter membrane, sonicate for 10min, and use it as the organic phase; take 500mL of ultrapure water, filter with a 0.22μmMCE filter membrane, and use ultrasonic treatment for 10min as the aqueous phase;

[0057] (2) Preparation of mixed standard stock solution:

[0058] Weigh 1mg glycolic acid, 1mg ethylene glycol, 1mg 50wt% glyoxylic acid aqueous solution, 1mg acetic acid, 1mg acetaldehyde and 10mg 40wt% formaldehyde aqueous solution in a 100mL volumetric flask, dilute to volume with ethanol, shake well for 1-2min , to obtain a mixed standard stock solution; in the mixed standard stock solution, the concentration of each component is as follows: glycolic acid 10 μg / mL, ethylene glycol 10 μg / mL, glyoxylic a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com