Double-layer processed all-polymer organic solar cell and preparation process thereof

A technology of solar cells and preparation process, applied in the field of solar cells, can solve the problems of instability and low efficiency of organic fluorescent materials, and achieve the effects of good light stability, effective charge transport, and inhibition of charge recombination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

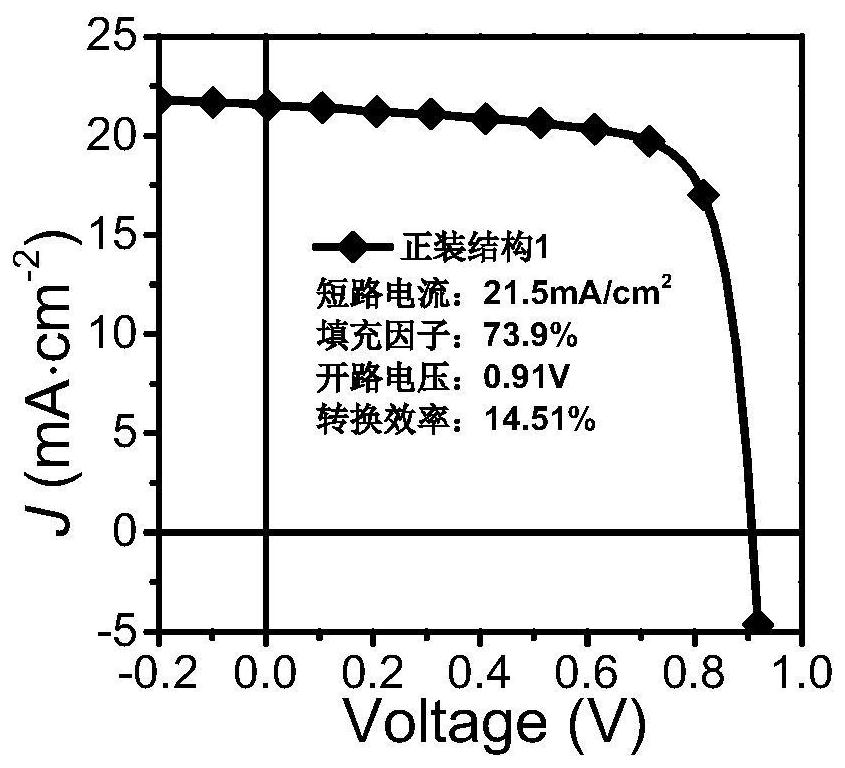

Embodiment 1

[0045] A positive-type bilayer processed all-polymer organic solar cell

[0046] 1) Transparent electrode preparation: The glass substrate and the substrate composed of transparent conductive cathode ITO were ultrasonically cleaned with isopropanol, detergent solution, deionized water three times, and isopropanol for 15 minutes, and then dried in an oven. The surface of the transparent cathode ITO is placed under the ozone-ultraviolet lamp for 15 minutes, covered with a watch glass, and taken out;

[0047] 2) Hole transport layer: Take 5.40 mg 2PACz (anode interface) in a small reagent bottle, pipette 2000 μL of absolute ethanol into the small reagent bottle to dissolve 2PACz, wrap the bottle cap tightly with disposable tape and place it under a magnetic force In the heater, heat at 50°C and 100 r / min for 0.5~1 hour;

[0048] Spin-coat 2PACz solution on the transparent conductive ITO surface of the battery substrate at a speed of 3000 r / min for 30 s as a hole transport layer,...

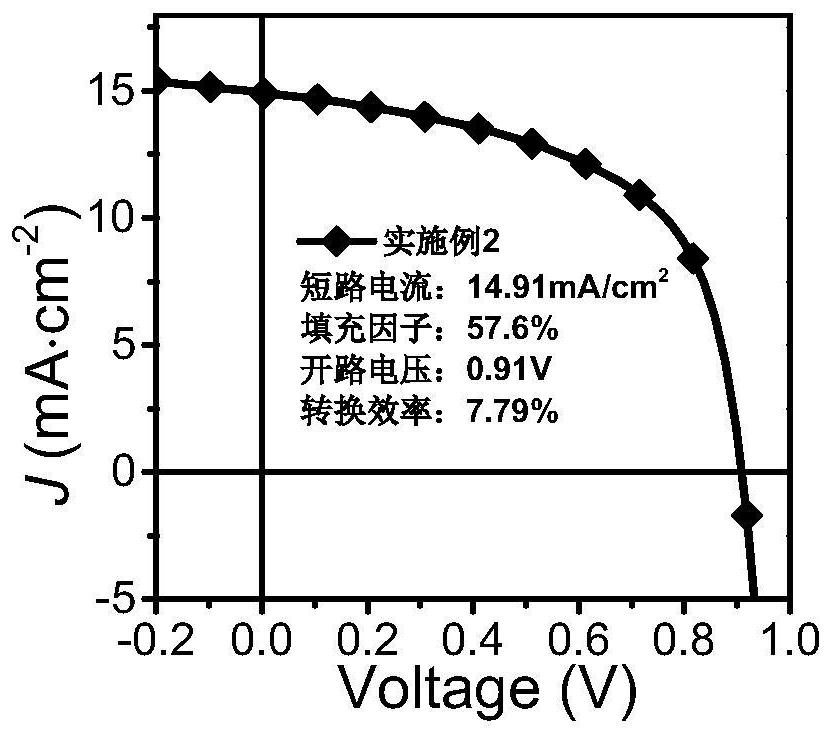

Embodiment 2

[0057] An all-polymer organic solar cell with reverse bilayer processing

[0058] 1) Transparent electrode layer: The glass substrate and the substrate composed of transparent conductive cathode ITO were ultrasonically cleaned with isopropanol, detergent solution, deionized water three times, and isopropanol for 15 minutes, and then dried in an oven. The surface of the transparent cathode ITO is placed under the ozone-ultraviolet lamp for 15 minutes, covered with a watch glass, and taken out;

[0059] 2) Electron transport layer: take 300.00 mg ZnAc 2 In a small reagent bottle, pipette 3000 μL 2-methoxyethanol, 83 μL ethanolamine to the small reagent bottle and ZnAc 2 Dissolve, wrap the bottle cap tightly with disposable tape, put it in a magnetic heater, and heat it at 50°C and 200 r / min for 6 hours;

[0060] Spin-coat ZnO solution on the surface of the transparent conductive cathode ITO of the battery substrate at a speed of 3000r / min as an electron transport layer, and an...

Embodiment 3

[0069] An all-polymer battery for inverse bilayer processing of organic solar energy

[0070] 1) Transparent electrode layer: The glass substrate and the substrate composed of transparent conductive cathode ITO were ultrasonically cleaned with isopropanol, detergent solution, deionized water three times, and isopropanol for 15 minutes, and then dried in an oven. The surface of the transparent cathode ITO is placed under the ozone-ultraviolet lamp for 15 minutes, covered with a watch glass, and taken out;

[0071] 2) Electron transport layer: take 300.00 mg ZnAc 2 In a small reagent bottle, pipette 3000 μL 2-methoxyethanol, 83 μL ethanolamine to the small reagent bottle and ZnAc 2 Dissolve, wrap the bottle cap tightly with disposable tape, put it in a magnetic heater, and heat it at 50°C and 200 r / min for 6 hours;

[0072] Spin-coat ZnO solution on the surface of the transparent conductive cathode ITO of the battery substrate at a speed of 3000r / min as an electron transport l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com