Tail gas treatment method for producing epoxypropane through cumene co-oxidation method

A technology of cumene peroxidation and propylene oxide, applied in chemical instruments and methods, combustion methods, separation methods, etc., can solve the problems of difficulty in condensation of cumene, poor atom economy, and high unit consumption of cumene, and achieves The effect of saving one-time investment, saving operating costs, and reducing the size of heat exchangers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

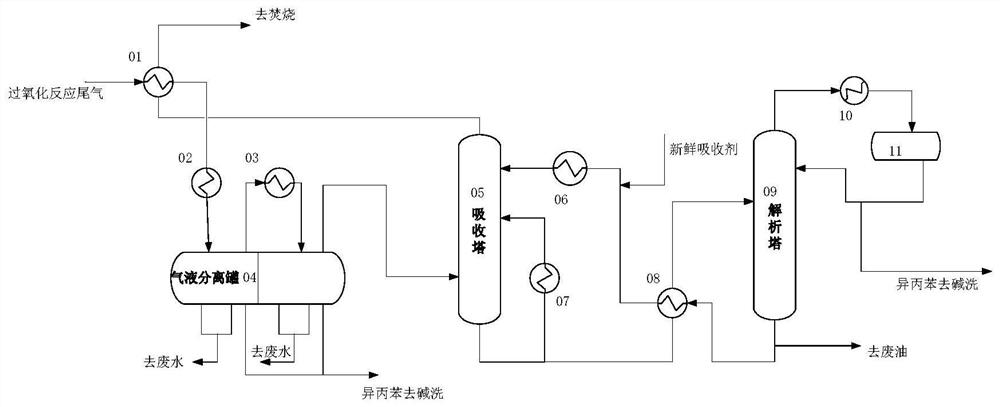

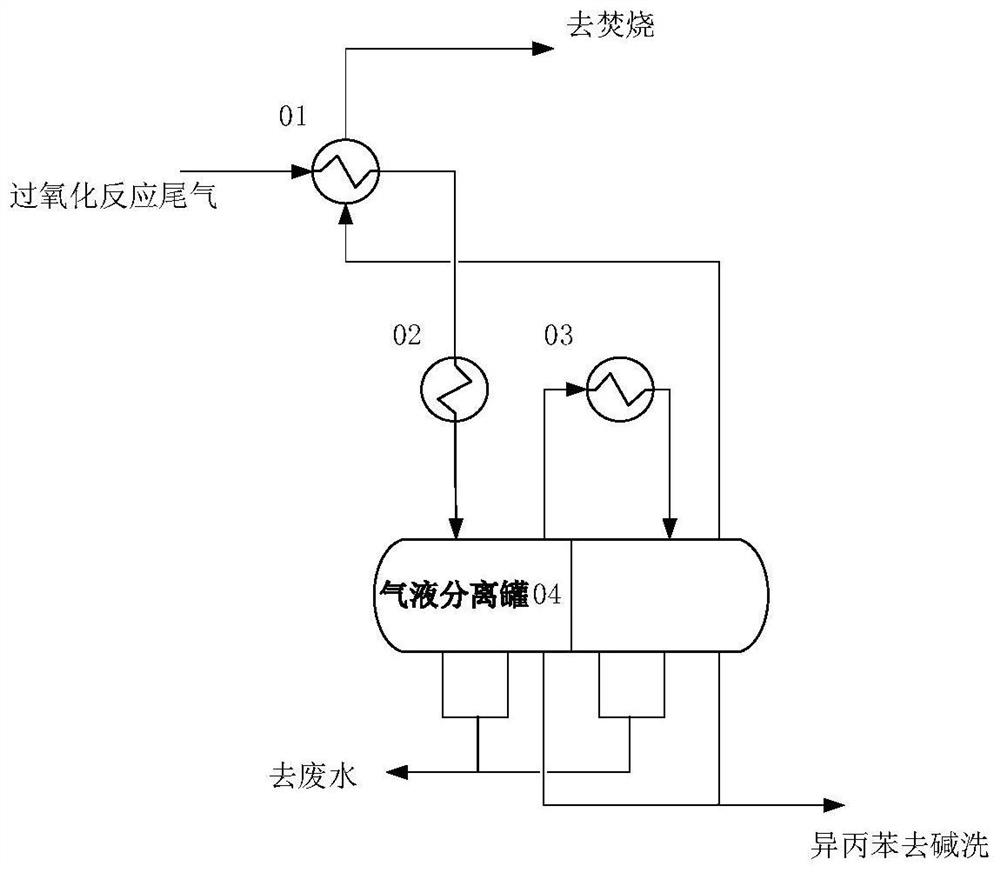

[0049] Embodiment 1: as figure 1 , a tail gas treatment method for the production of propylene oxide by co-oxidation of cumene, including that the tail gas of the peroxidation reaction directly goes to the first heat exchanger 01, and the outlet stream of the first heat exchanger 01 goes to the second heat exchanger with circulating water as the refrigerant Heat exchanger 02, the outlet of the second heat exchanger 02 goes to the gas-liquid separation tank 04, and the separated gas phase enters the third heat exchanger 03 (deep condenser), and then enters the gas-liquid separator 04 to separate the liquid phase, and the separated gas phase Enter the absorption tower 05, the gas phase at the top of the absorption tower enters the first heat exchanger 01 for heat exchange and then goes to incineration, one part of the tower kettle is cooled by the fifth heat exchanger 07 and then returns to the middle of the absorption tower, and the other part goes to the sixth heat exchanger 08...

Embodiment 2

[0055] Referring to the method of Example 1, after the peroxidation tail gas and the absorption tail gas at 20°C are directly exchanged in a heat exchanger at 70°C, the temperature is lowered to 40°C in the first stage, and the gas-liquid separation is realized after two-stage condensation, and the gas phase temperature after separation is 15°C Go to the absorption tower, the absorption tower adopts fresh absorption liquid as dicumyl (isomers), tricumene, dimethyl benzyl alcohol, the mass ratio is 0.2:0.1:0.03, and the amount of fresh absorbent added: The circulation volume of the absorbent at the bottom of the desorption tower: the circulation volume of the absorption liquid at the bottom of the absorption tower: the tail gas flow mass ratio is 0.3:3:30:120. The absorption liquid in the absorption tower enters the desorption tower to recover cumene. The mass ratio of the absorption liquid from the bottom of the absorption tower to the middle stream of the absorption tower and...

Embodiment 3

[0058] Referring to the method of Example 1, after the peroxidation tail gas and the absorption tail gas at 20°C are directly exchanged in a heat exchanger at 70°C, the temperature is lowered to 40°C in the first stage, and the gas-liquid separation is realized after two-stage condensation, and the gas phase temperature after separation is 15°C Go to the absorption tower, the absorption tower adopts the fresh absorption liquid as dicumyl (isomer), tricumene, dimethyl benzyl alcohol, the mass ratio is 0.5:0.3:0.05, the amount of fresh absorbent added: The circulation volume of the absorbent at the bottom of the desorption tower: the circulation volume of the absorption liquid at the bottom of the absorption tower: the tail gas flow mass ratio is 0.5:10:20:120. The absorption liquid in the absorption tower enters the desorption tower to recover cumene. The mass ratio of the absorption liquid at the bottom of the absorption tower to the middle stream of the absorption tower and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com