Molecular sieve photonic crystal film, preparation method and application thereof in detection of steam type and concentration

A photonic crystal, molecular sieve technology, applied in molecular sieves and alkali exchange compounds, chemical instruments and methods, phase influence characteristic measurement, etc., to achieve the effect of low cost, cost green and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

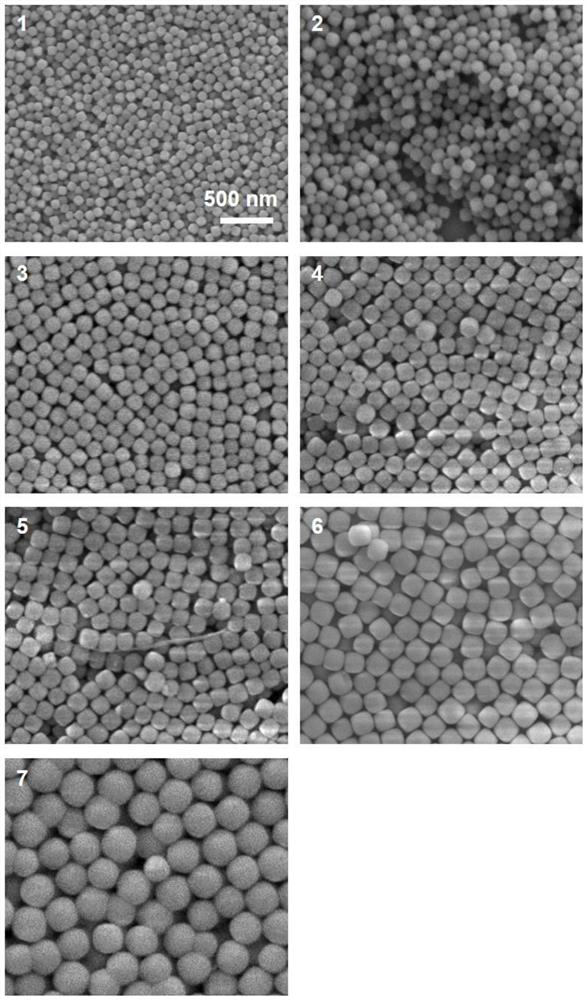

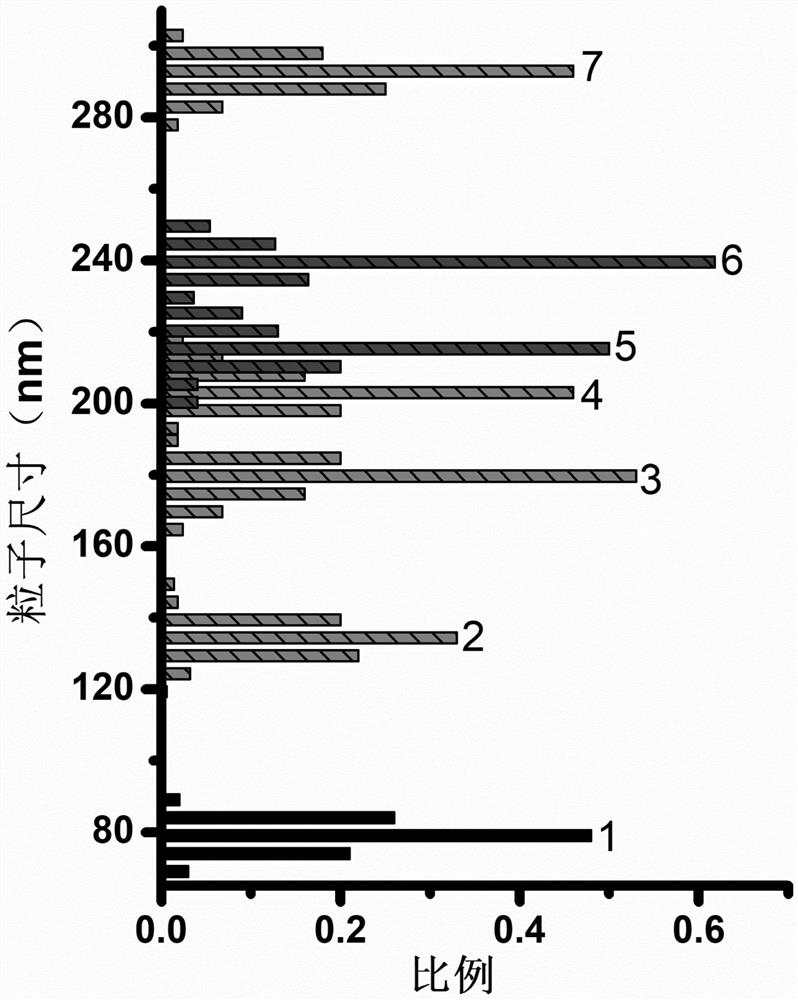

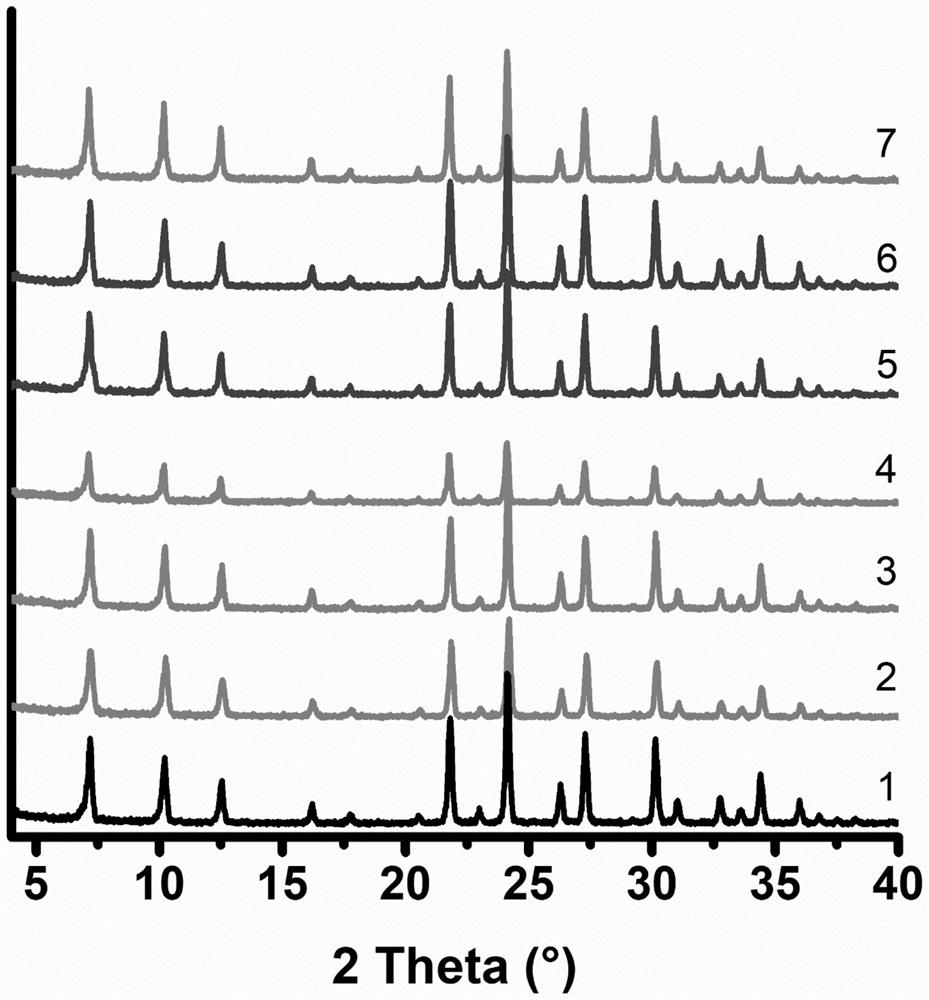

[0046] Example 1: Preparation of a molecular sieve photonic crystal film 1

[0047] (1) 13.10 g of tetramethylammonium hydroxide aqueous solution with a mass fraction of 25 wt % and 6.10 g of a sodium hydroxide aqueous solution with a mass fraction of 0.70 wt % were mixed and stirred evenly, then 1.0 g of silicic acid was added, heated and stirred at 50° C. until completely dissolved. After cooling to room temperature, add 0.5 g of aluminum isopropoxide and stir until dissolved. The obtained solution was aged at 25° C. for 12 hours, and then heated and crystallized at 60° C. for 48 hours in a flask. Finally, the crystallized product was repeatedly centrifuged and ultrasonically washed to obtain the LTA-type molecular sieve colloidal nanoparticle seed crystal particle 1, which was then dispersed in water to form an LTA-type molecular sieve colloidal nanoparticle seeding liquid 1 with a mass fraction of 2 wt%.

[0048] (2) 0.00g mass fraction of 2wt% LTA molecular sieve colloi...

Embodiment 2

[0051] Example 2: Preparation of a molecular sieve photonic crystal film 2

[0052] (1) The operation method is the same as in Example 1.

[0053] (2) 2.54g, mass fraction of 2wt% LTA molecular sieve colloidal nanoparticle seed liquid 1 and 4.23g, mass fraction of 0.70wt% sodium hydroxide aqueous solution were mixed uniformly at a mass ratio of 0.6:1, and then 1.1 g silicic acid, heated and stirred at 60°C until completely dissolved. After cooling to room temperature, add 0.8g of aluminum isopropoxide and stir to dissolve. The obtained solution was aged at 25° C. for 12 hours, and then placed in a flask and heated at 60° C. for 24 hours for crystallization. Finally, the crystallized product was repeatedly centrifuged and ultrasonically washed to obtain LTA molecular sieve colloidal nanoparticles 2, and then dispersed in water to form LTA molecular sieve colloidal nanoparticle solution 2 with a mass fraction of 6 wt%.

[0054] (3) Draw 5 mL of the LTA-type molecular sieve co...

Embodiment 3

[0056] Example 3: Preparation of a molecular sieve photonic crystal film 3

[0057] (1) The operation method is the same as in Example 1.

[0058] (2) 2.35g, mass fraction of 2wt% LTA molecular sieve colloidal nanoparticle seed liquid 1 and 4.70g, mass fraction of 0.70wt% sodium hydroxide aqueous solution were mixed uniformly at a mass ratio of 0.5:1, and then 1.2 g silicic acid, heated and stirred at 60°C until completely dissolved. After cooling to room temperature, 1.0 g of aluminum isopropoxide was added and stirred to dissolve. The obtained solution was aged at 30° C. for 24 hours, and then placed in a flask and heated at 60° C. for 24 hours for crystallization. Finally, the crystallized product was repeatedly centrifuged and ultrasonically washed to obtain LTA molecular sieve colloidal nanoparticles 3 , and then dispersed in water to form an LTA molecular sieve colloidal nanoparticle solution 3 with a mass fraction of 5 wt %.

[0059] (3) Draw 5 mL of the LTA molecula...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| dispersity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com