High-COD and high-salt waste liquid treatment technology

A high-salt waste liquid and technology technology, which is applied in the field of high COD and high-salt waste liquid treatment, can solve problems such as cost increase, flue salt crystallization blockage, rotary kiln coking, etc., and achieves reduction of treatment cost, obvious effect and applicability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

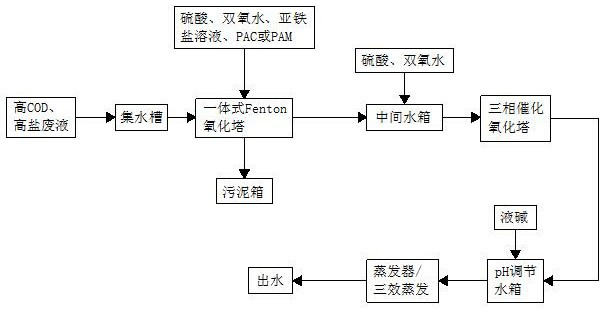

[0023] A high-COD, high-salt waste liquid treatment technology, the treatment process steps are as follows:

[0024] A. High ammonia nitrogen and high COD waste liquid is collected in the sump, and pumped to the integrated Fenton oxidation tower through the pipeline;

[0025] B. In the integrated Fenton oxidation tower, the pumps transport sulfuric acid, hydrogen peroxide, ferrous salt solution, sodium hydroxide, PAC, and PAM to the tower respectively, and the pH value of the waste liquid is adjusted to 2-4 before entering the Fenton oxidation zone in the tower , the Fenton oxidation area in the tower adopts medium-temperature Fenton oxidation technology to keep the Fenton reaction area at 50-60°C; then the waste liquid enters the flocculation sedimentation area in the tower, the pH is adjusted to about 8, and flocculant PAC or PAM is added to remove a large amount of COD, precipitates into the sludge tank at the bottom of the integrated Fenton oxidation tower, and the treated...

Embodiment 2

[0029] A high-COD, high-salt waste liquid treatment technology, the treatment process steps are as follows:

[0030] A. High ammonia nitrogen and high COD waste liquid is collected in the sump, and pumped to the integrated Fenton oxidation tower through the pipeline;

[0031] B. In the integrated Fenton oxidation tower, the pumps transport sulfuric acid, hydrogen peroxide, ferrous salt solution, sodium hydroxide, PAC, and PAM to the tower respectively, and the pH value of the waste liquid is adjusted to 2-4 before entering the Fenton oxidation zone in the tower , the Fenton oxidation area in the tower adopts medium-temperature Fenton oxidation technology to keep the Fenton reaction area at 50-60°C; then the waste liquid enters the flocculation sedimentation area in the tower, the pH is adjusted to about 8, and flocculant PAC or PAM is added to remove a large amount of COD, precipitates into the sludge tank at the bottom of the integrated Fenton oxidation tower, and the treated...

Embodiment 3

[0035] A high-COD, high-salt waste liquid treatment technology, the treatment process steps are as follows:

[0036] A. High ammonia nitrogen and high COD waste liquid is collected in the sump, and pumped to the integrated Fenton oxidation tower through the pipeline;

[0037] B. In the integrated Fenton oxidation tower, the pumps transport sulfuric acid, hydrogen peroxide, ferrous salt solution, sodium hydroxide, PAC, and PAM to the tower respectively, and the pH value of the waste liquid is adjusted to 2-4 before entering the Fenton oxidation zone in the tower , the Fenton oxidation area in the tower adopts medium-temperature Fenton oxidation technology to keep the Fenton reaction area at 50-60°C; then the waste liquid enters the flocculation sedimentation area in the tower, the pH is adjusted to about 8, and flocculant PAC or PAM is added to remove a large amount of COD, precipitates into the sludge tank at the bottom of the integrated Fenton oxidation tower, and the treated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com