Method for preparing drug metabolic enzyme-porous material compound and application

A porous material and a technology for preparing drugs, applied in the field of medicine, can solve the problems of complex preparation process, large substrate mass transfer resistance, low enzyme activity, etc., and achieve the effects of simple preparation, improved stability and good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

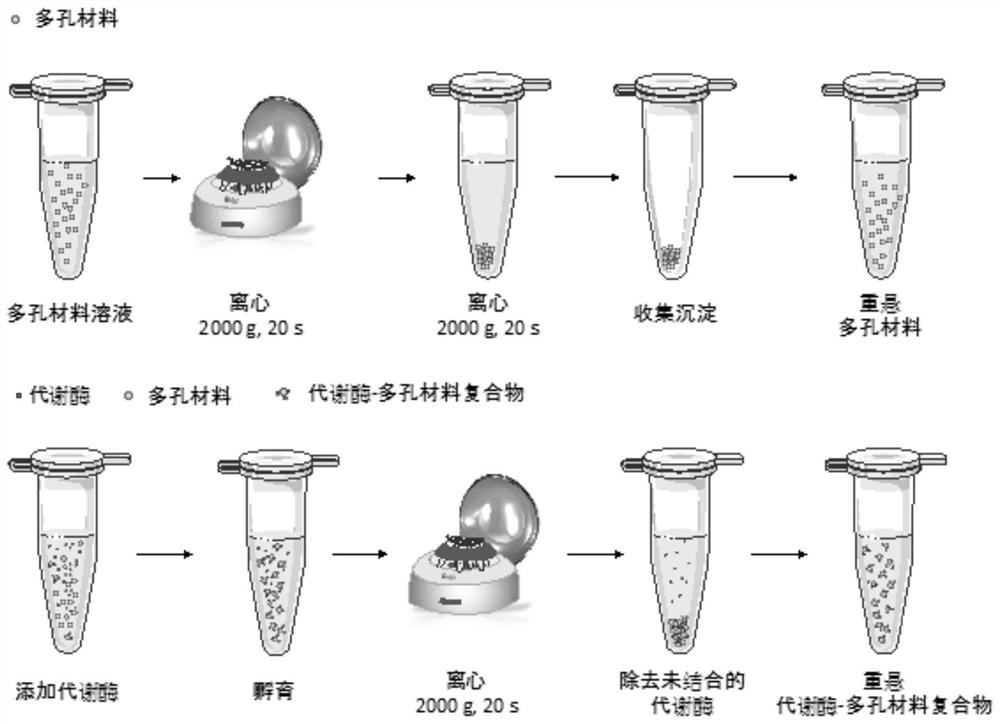

[0021] Example 1: Preparation of drug-metabolizing enzyme-porous material composite

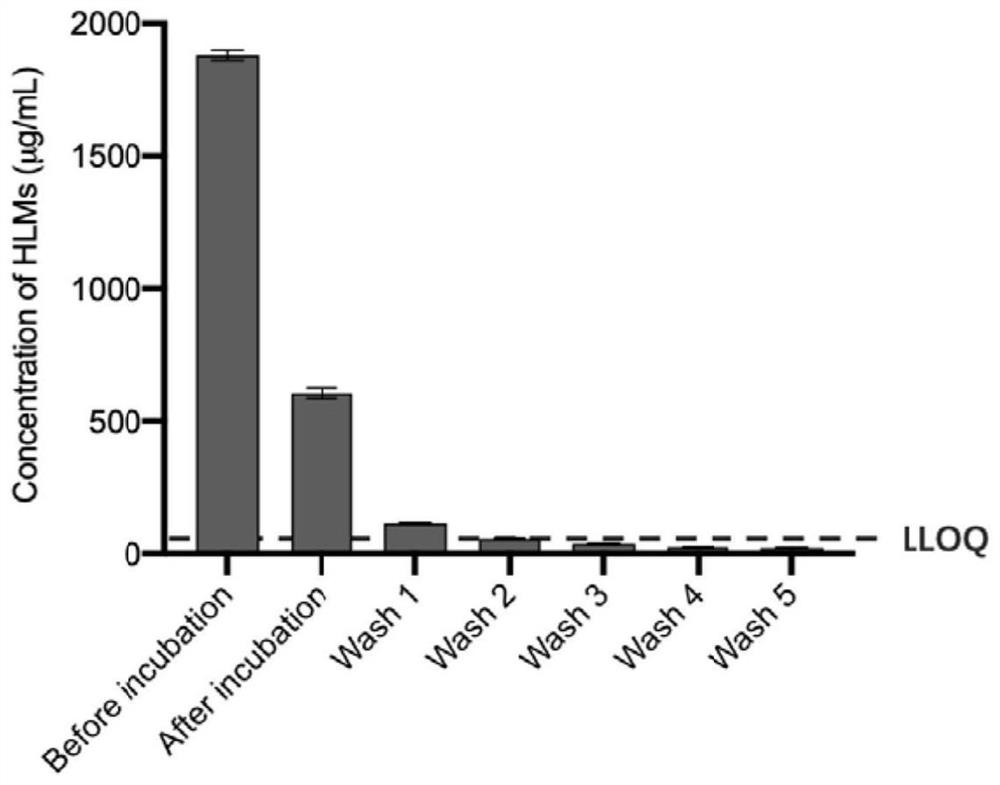

[0022] Preparation steps such as figure 1 As shown, pre-soak an appropriate amount of ZSM-48 molecular sieve with 100mM phosphate buffer (PB) with pH = 7.4 for 30min, centrifuge in a handheld centrifuge for 20s (2000g), retain the precipitate, redissolve in PB buffer, repeat the above operation 3 times , fully remove the unprecipitated impurities in the supernatant, and set aside. Dilute the microsomal stock solution with PB to 2mg / mL, add it to ZSM-48 prepared in advance, vortex 5s to mix well, then absorb at 4°C for 24h, centrifuge at 2000g for 20s, and wash the precipitate with PB buffer for more than 3 times , removing unbound enzymes in the supernatant to obtain drug-metabolizing enzyme-porous material complexes. Before and after adsorption, the BCA method was used to measure the change of protein concentration in the buffer as follows: figure 2 As shown, the protein binding amount e...

Embodiment 2

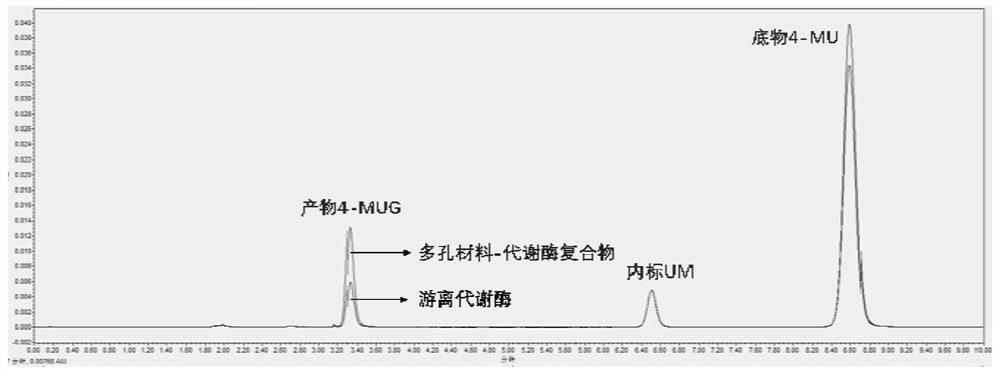

[0023] Example 2: Metabolic capacity of drug-metabolizing enzyme-porous material complex

[0024] Microsomes contain almost all phase I and phase II drug metabolizing enzymes, the most important ones are cytochrome P450 and UGT enzymes, which are involved in the metabolism of almost 65% of clinical drugs, so the broad-spectrum probe substrates of UGT enzymes are first selected 4-methylumbelliferone (4-MU) was used to verify the metabolic ability of the drug-metabolizing enzyme-porous material complex. 200μL incubation system, containing 100mMPB buffer (pH=7.4), 10mM MgCl 2 , 2.5mM UDPGA, 400μM 4-MU, 50μg / mg protein alamethicin and 0.1mg / mL microsome or drug metabolizing enzyme-porous material complex. The reaction was started by adding UDPGA last, and incubated at 37°C for 30min. The metabolic capacity of the drug-metabolizing enzyme-porous material complex was characterized by detecting the amount of the phase II metabolite 4-MUG of 4-MU in the supernatant by high performan...

Embodiment 3

[0025] Example 3: Number of repeated uses of the drug-metabolizing enzyme-porous material composite

[0026] Repeat the steps in Example 2, except that after incubation for 30 minutes, centrifuge at 2000g for 20s, separate the supernatant for HPLC detection, retain the drug-metabolizing enzyme-porous material complex precipitation, wash the buffer 3 times, and add The corresponding substances in the incubation system were catalyzed again, repeated 10 times, and the amount of catalyzed metabolites were detected 10 times respectively to characterize the reusability of the drug metabolizing enzyme-porous material complex. The results are as follows Figure 4 It can be seen that the residual activity of the enzyme remains above 60% when the catalysis is repeated 10 times continuously, realizing the repeated utilization of the metabolic enzyme.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com