Gel electrolyte diaphragm treatment method

A technology of gel electrolyte and processing method, which is applied in the field of preparation of in-situ gel electrolyte inside the battery, can solve the problems of complex preparation method, complicated manufacturing process, and harsh gelation conditions, and achieve simple preparation method, easy-to-obtain raw materials, Effects that are easy to store

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

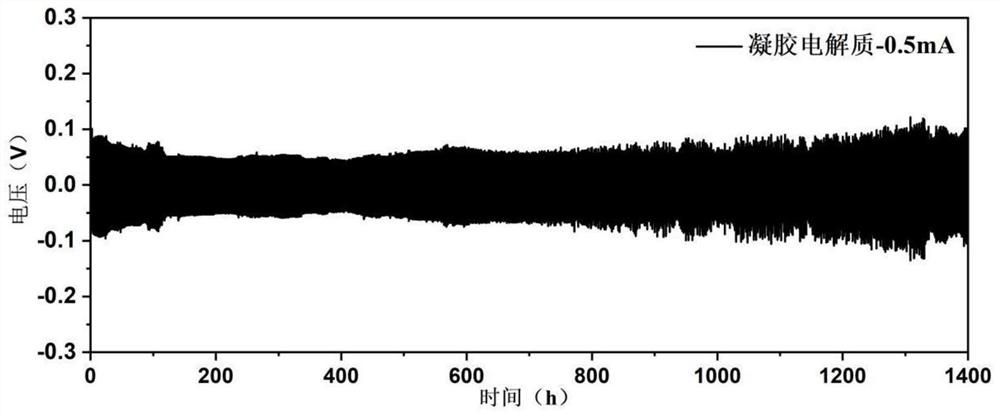

Embodiment 1

[0037] 1) ethylene glycol dimethyl ether and boron trifluoride ether solvent are mixed according to volume ratio 10:1 to obtain a prefabricated solution with an initiator;

[0038] 2) After coating the prefabricated solution on one side of the common polypropylene separator, after the DME is volatilized, the battery is assembled; wherein, 7.06 ml of the prefabricated solution is applied per square centimeter of the separator;

[0039] 3) Configure the electrolyte, the solvent is 1,3-dioxane and ethylene glycol dimethyl ether, the volume ratio of the two is 1,3-dioxane:ethylene glycol dimethyl ether=7:3, and the solute is lithium salt LiTFSI and LiNO 3 , 1M (mol / L) LiTFSI, 0.1M LiNO 3 ;

[0040] 4) drip electrolyte to the diaphragm obtained in the 2) step, assemble into a battery together with the positive electrode and the negative electrode, the side of the diaphragm with an initiating Lewis acid on the surface faces the positive electrode, and 3.09 microliters of steps are...

Embodiment 2

[0051] The other steps are the same as in Example 1, except that, in step 2), the position of changing the prefabricated solution of boron trifluoride to treat the diaphragm is to treat the diaphragm on both sides. In situ gelation of the electrolyte is induced after treatment. The other steps of the comparative sample are the same as those of Comparative Example 1.

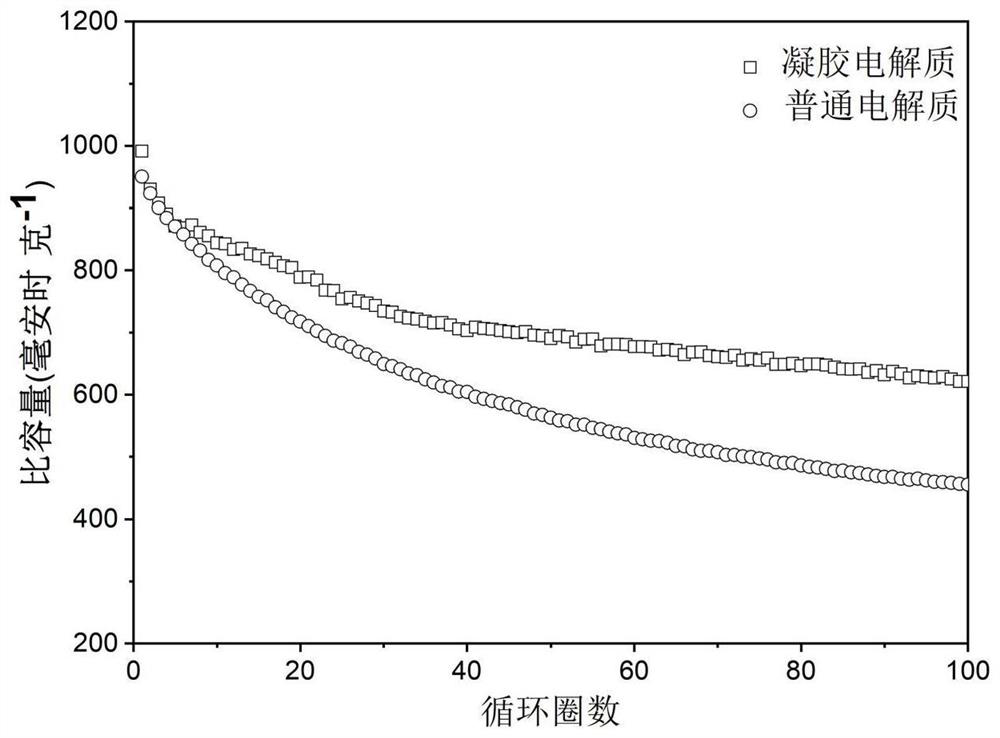

[0052] Applied in the lithium-sulfur battery system under the current of 0.5C (1C=1675mAh / g), the capacity of the gel electrolyte battery formed by in-situ gelation of the separator with initiating Lewis acid on both sides after 100 cycles of stable cycling Attenuate from 990 mAh / g to about 700 mAh / g, drop 3.09 microliters of the electrolyte obtained in step 3) of Example 1 on both sides of the diaphragm per square centimeter surface, and the capacity of the ordinary liquid electrolyte is reduced from 1000 mAh compared to the same period last year. / g decays to around 450mAh / g,

[0053] The amount of electrolyt...

Embodiment 3

[0055] The other steps are the same as in Example 1, the difference is that in step 5) the positive electrode sulfur loading is 2.5 mg / cm 2 , and the separator is applied at a current of 0.5C (1C=1675 mAh / g) with an initiating Lewis acid on the surface. The amount of gel electrolyte formed by in-situ gelation is still 3.09 μl / cm 2 , except that the positive electrode material is the step 5 of Example 1) The positive electrode sulfur loading is 2.5 mg / cm 2 , and other conditions are the same as in Comparative Example 1. In the lithium-sulfur battery system, the battery system formed by in-situ gelation of the separator treated with Lewis acid as the electrolyte has a stable capacity of 1300 mAh / g after 100 cycles attenuates to about 600 mAh / g, which is comparable to that of ordinary liquid electrolyte batteries. The capacity of the system has been maintained at about 400 mAh / g, which does not have practical application value. Therefore, the amount of gel electrolyte formed by in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com