Solid electrolyte composite membrane and preparation method thereof

A technology of solid electrolyte and composite membrane, which is applied in the manufacture of electrolyte batteries, non-aqueous electrolytes, and non-aqueous electrolyte batteries. Strength, improvement of ionic conductivity and stability, improvement of safety and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

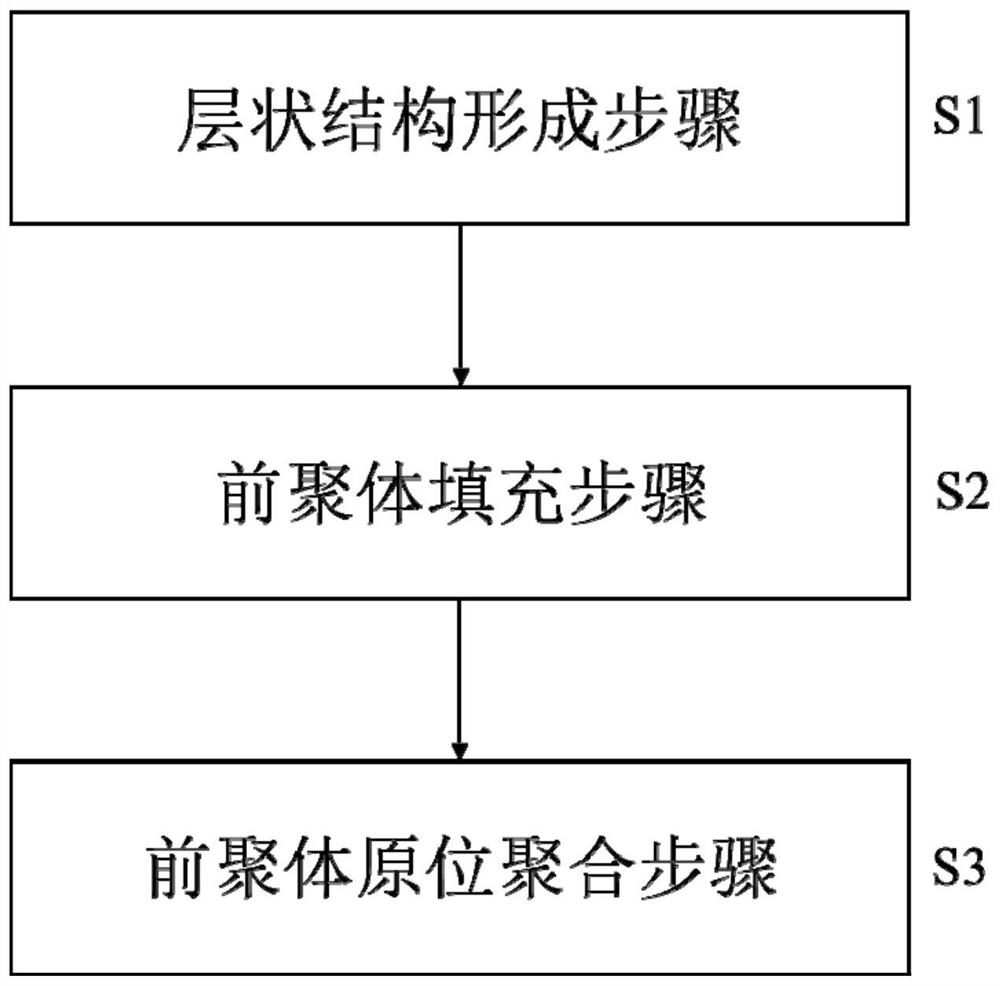

[0049] Please refer to image 3 Another specific embodiment of the present invention describes a method for preparing the above-mentioned solid electrolyte composite membrane, comprising: a layered structure forming step (S1), a prepolymer filling step (S2), and a prepolymer in-situ polymerization step ( S3).

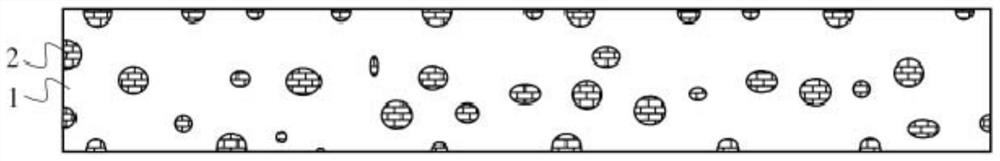

[0050] Layered structure forming step (S1): forming an inorganic solid electrolyte into a layered structure with internal pores.

[0051] Specifically, the raw materials of the inorganic solid electrolyte can be calcined to form a layered structure of the inorganic solid electrolyte. This method can be the same as the prior art, and is known to those skilled in the art, and will not be repeated here.

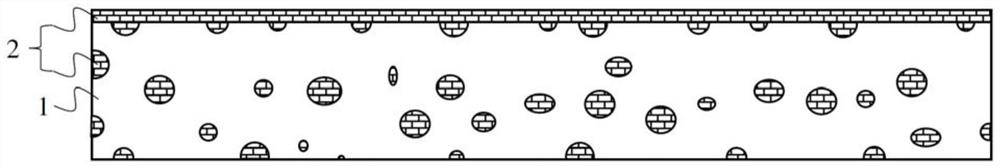

[0052] Prepolymer filling step (S2): filling a prepolymer into the internal pores of the layered structure of the inorganic solid electrolyte.

[0053] Specifically, the prepolymer is a unit of a subsequent organic polymer, such as a monomer or a copolymer, and in order...

Embodiment 1

[0064] Choose LiOH·H 2 O as lithium source, La(OH) 3 As a source of lanthanum, ZrO 2 As a source of zirconium, Ta 2 o 5 as a source of tantalum. Weigh an appropriate amount of LiOH·H according to the stoichiometric ratio (15% excess lithium source) 2 O, La(OH) 3 , ZrO 2 and Ta 2 o 5 . After the above four raw materials were moved into the zirconia ball mill jar, zirconia balls with a diameter of 3 mm were added (the weight ratio of the ball to material was 10:1), and the speed was set at 400 rpm, and the ball milled for 12 hours. Transfer the mixed mixture powder to a corundum crucible, put it into a box-type muffle furnace for calcination, and calcine at a temperature of 950°C for 12 hours. After natural cooling, take out the LLZTO powder. The LLZO powder is subjected to secondary ball milling, and the setting of the weight ratio of the ball to material, the milling speed and the time is consistent with the aforementioned mixing ball milling. After ball milling, t...

Embodiment 2

[0068] The preparation process of the LLZTO powder and the green body is the same as in Example 1, and the secondary calcination temperature of the green body is 1100° C., and the temperature is kept for 12 hours. Finally, the LLZTO diaphragm was obtained by natural cooling, and the density of the diaphragm was measured to be 90% by the Archimedes drainage method.

[0069] The preparation process of the polymer prepolymer solution is the same as in Example 1.

[0070] The above-mentioned LLZTO membrane was quickly placed in the polymer prepolymer solution and soaked for several minutes to fully wet and penetrate into the internal pores. After wiping off a large amount of solution remaining on the surface, let it stand at room temperature for 24 hours to obtain a solid electrolyte composite membrane. The room temperature lithium ion conductivity of this solid electrolyte composite membrane is 5.7×10 -4 S cm -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com