Production process and technical application of composite functional fermented feed

A technology of fermented feed and production process, applied in application, animal feed, animal feed and other directions, can solve the problems of inability to effectively improve the resistance of livestock, easy breeding of insect pests in feces, affecting food safety, etc., to enhance cellular immunity and humoral immunity. , Improve meat flavor and promote animal growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

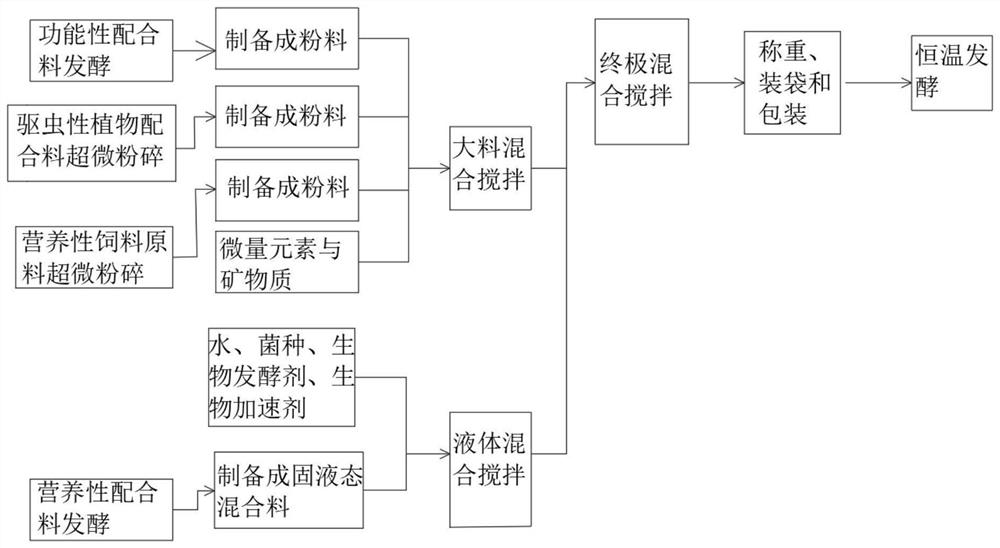

[0072] see figure 1 , the present invention provides a technical solution: a compound functional fermented feed and its production process, including functional ingredients, insect repellent plant ingredients, nutritious protein feed raw materials and nutritious vitamin ingredients, compound functional fermented The feed production process includes the following steps:

[0073] Step S1, the functional batch is fermented and prepared into powder;

[0074] Step S1 further comprises the following steps:

[0075] S11, sealing and fermenting 50% of fresh Houttuynia cordata, 48% of water and 2% of auxiliary agent for more than 10-20 days;

[0076] S12, sealing and fermenting 50% of fresh honeysuckle, 48% of water and 2% of auxiliary agent for more than 10-20 days;

[0077] S13, 50% fresh mulberries, 48% water and 2% additives, sealed and fermented for more than 10-20 days;

[0078] S14, sequentially select dried red ginseng, dried ginkgo fruit, dried safflower, dried kelp and dr...

Embodiment 2

[0126] A compound functional fermented feed, comprising functional compounding material, insect repellent plant compounding material, nutritional feed and nutritional compounding material, the functional compounding material is composed of the following raw materials in weight ratio: dry red ginseng 3%, dried ginkgo fruit 3%, dried safflower 3%, dried kelp 3%, dried bamboo leaf whole grass 3%, fresh Houttuynia cordata 5%, fresh Imperata rhizome 5%, fresh honeysuckle fermented product 15%, fresh mulberry fermented product 5% , dried sweet potato 20%, water 30%;

[0127] The insect repellent plant compound is composed of the following raw materials: agarwood, shijunzi and Dabupi, and the weight ratio of agarwood, shijunzi and Dabupi is 1:1:1;

[0128] The nutritional feed is composed of raw materials in the following weight ratio: corn, meal and wheat, and the weight ratio of corn, meal and wheat is 1:1:3;

[0129] The nutritional compounding material is composed of the followi...

Embodiment 3

[0131] A compound functional fermented feed, including functional compound material, insect repellent plant compound material, nutritional feed and nutritional compound material, the functional compound material is composed of the following raw materials in weight ratio: dry red ginseng 1%, dried ginkgo fruit 1%, dried safflower 1%, dried kelp 1%, dried bamboo leaf whole grass 1%, fresh Houttuynia cordata fermented product 6%, fresh coriander root 8%, fresh honeysuckle fermented product 35%, fresh mulberry fermented product 5% , dried sweet potato 25%, water 25%;

[0132] The insect repellent plant compound is composed of the following raw materials: agarwood, gentile and big belly skin, and the weight ratio of agarwood and smith is 1:1;

[0133] The nutritional feed is composed of raw materials in the following weight ratio: corn, meal and wheat, and the weight ratio of corn and meal is 1:3;

[0134] The nutritional batch is composed of the following raw materials: corn stal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com