Solifenacin succinate tablet and preparation method thereof

A solifenacin succinate tablet technology, which is applied in pill delivery, pharmaceutical formulations, medical preparations of non-active ingredients, etc., can solve the problem of ensuring the content and uniformity of active ingredients in solifenacin succinate tablets, amber Solifenacin acid has poor fluidity and compressibility, which affects drug efficacy and drug safety, so as to improve drug safety, ensure drug safety, and increase disintegration speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

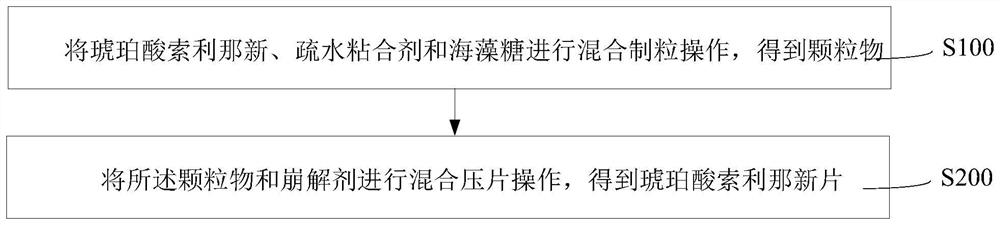

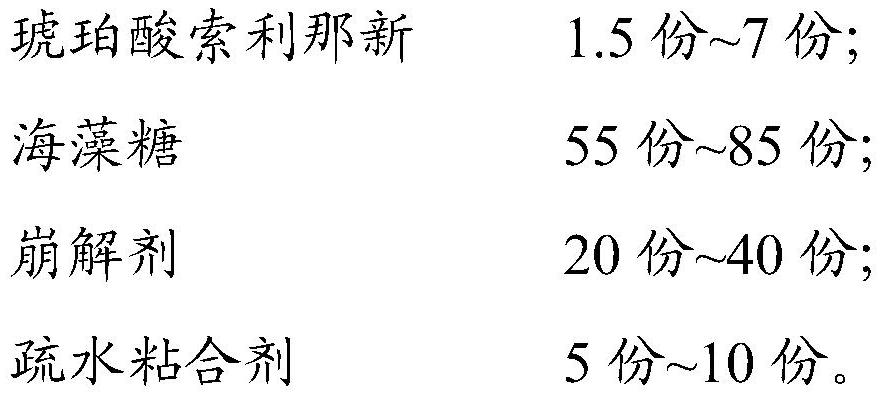

[0056] The present application also provides a preparation method of solifenacin succinate tablet, which is used to prepare the solifenacin succinate tablet of any one of the above embodiments. The preparation method of solifenacin succinate tablet comprises part or all of the following steps: carrying out mixing and granulation operation of solifenacin succinate, hydrophobic binder and trehalose to obtain granules; Mixing and tableting operation, solifenacin succinate tablets are obtained.

[0057] The preparation method of the above-mentioned solifenacin succinate tablet, after making solifenacin succinate, hydrophobic binder and trehalose carry out mixed granulation operation to form granules, then make granules and disintegrating agent carry out mixed tabletting operation , effectively avoiding the addition of the disintegrating agent, the disintegrating agent dilutes the trehalose, thereby weakening the hygroscopic effect of the trehalose on solifenacin succinate and redu...

Embodiment 1

[0083] Weighing: Solifenacin succinate 1.5kg, trehalose 55kg, maltose 5kg, dry starch 20kg, hydroxypropyl cellulose 1kg and magnesium stearate 1kg;

[0084] Granulation: Mix 1.5 kg of solifenacin succinate and 45 kg of trehalose, then mix with 4 kg of maltose, and granulate to form solifenacin succinate granules;

[0085] Tablet compression: mix solifenacin succinate granules, trehalose 10kg, dry starch 20kg, hydroxypropyl cellulose 1kg, maltose 1kg and magnesium stearate 1kg, and compress into tablets to form solifenacin succinate tablets.

Embodiment 2

[0087] Weighing: Solifenacin succinate 2.5kg, trehalose 60kg, maltose 6kg, carboxymethyl starch sodium 25kg, poloxamer 1kg and calcium stearate 1kg;

[0088] Granulation: Mix 2.5kg of solifenacin succinate and 50kg of trehalose, then mix with 5kg of maltose, and granulate to form solifenacin succinate granules;

[0089] Tablet compression: mix solifenacin succinate granules, sodium carboxymethyl starch 25kg, poloxamer 2kg, trehalose 10kg, maltose 1kg and calcium stearate 1kg, and compress into tablets to form solifenacin succinate tablets ;

[0090] Coating: sucrose syrup and solifenacin succinate tablets are placed in a coating machine for coating to obtain solifenacin succinate coated tablets.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com