Drug-carrying polymer wood/bamboo modifier, and production and application methods thereof

A technology of drug-loaded polymer and modifier, applied in the direction of wood impregnation, wood treatment, impregnated wood, etc., can solve the problems of low horizontal grain tensile strength, lack of wood rays, etc., achieve low cost, no pollution to the environment, reduce Water and hygroscopic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1 (contrasted with the corresponding raw material and weight ratio value of embodiment 1 in Table 1):

[0028] First, 25.0 parts of acrylic acid as a water-soluble monomer, 6.0 parts of polyethylene glycol as a water-soluble polymer, 0.45 parts of ammonium persulfate as a water-soluble initiator, and 0.2 parts of N, N'-submerged as a crosslinking agent Methylbisacrylamide and 0.15 parts of 1-ethyl-(3-dimethylaminopropyl) carbodiimide hydrochloride were respectively dissolved in 57.6 mL of water; then 5.0 parts of tertiary ethylene carbonate as an oil-soluble monomer Esters, 0.2 parts of propiconazole as fungicide and 0.1 part of iodopropynyl butyl carbamate, 0.1 part of emamectin benzoate as insecticide were dissolved in 5.0 parts of butanol solution as organic solvent, and stirred until completely Dissolve, add 0.2 parts of nonylphenol polyoxyethylene ether and 0.4 parts of polyoxyethylene lauryl ether phosphate as surfactants, stir again until completely di...

Embodiment 2-8

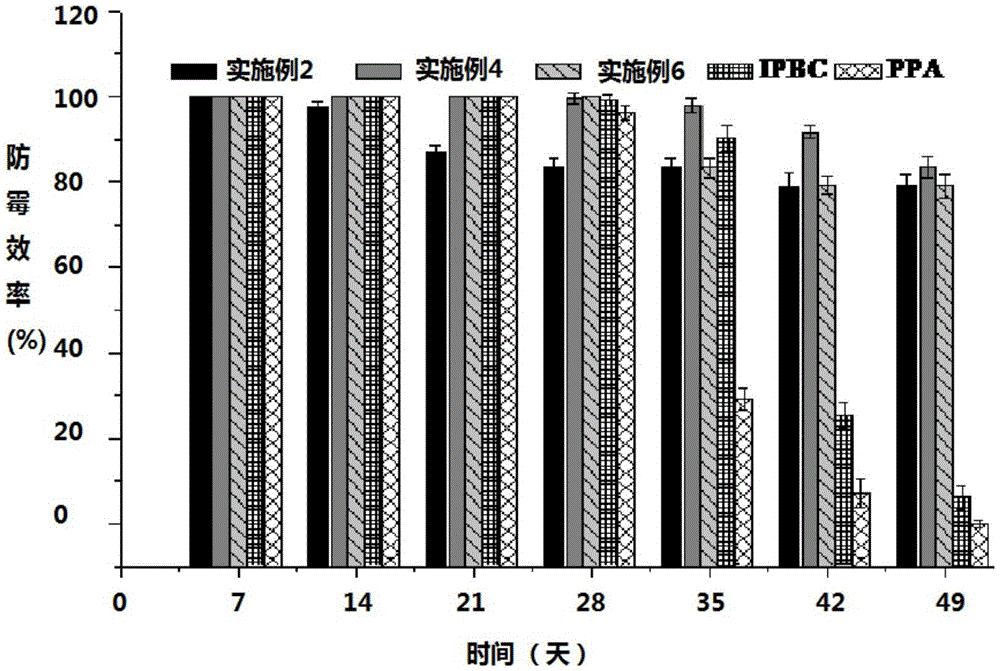

[0030] All the other examples 2-8, all the raw materials of corresponding examples in the comparison table and the proportioning value by weight, and the method identical with embodiment 1 makes this size stabilization and antibacterial worm wood bamboo material modifier, all can reach described Technical effect, wherein preferred with embodiment 2,4 and 6.

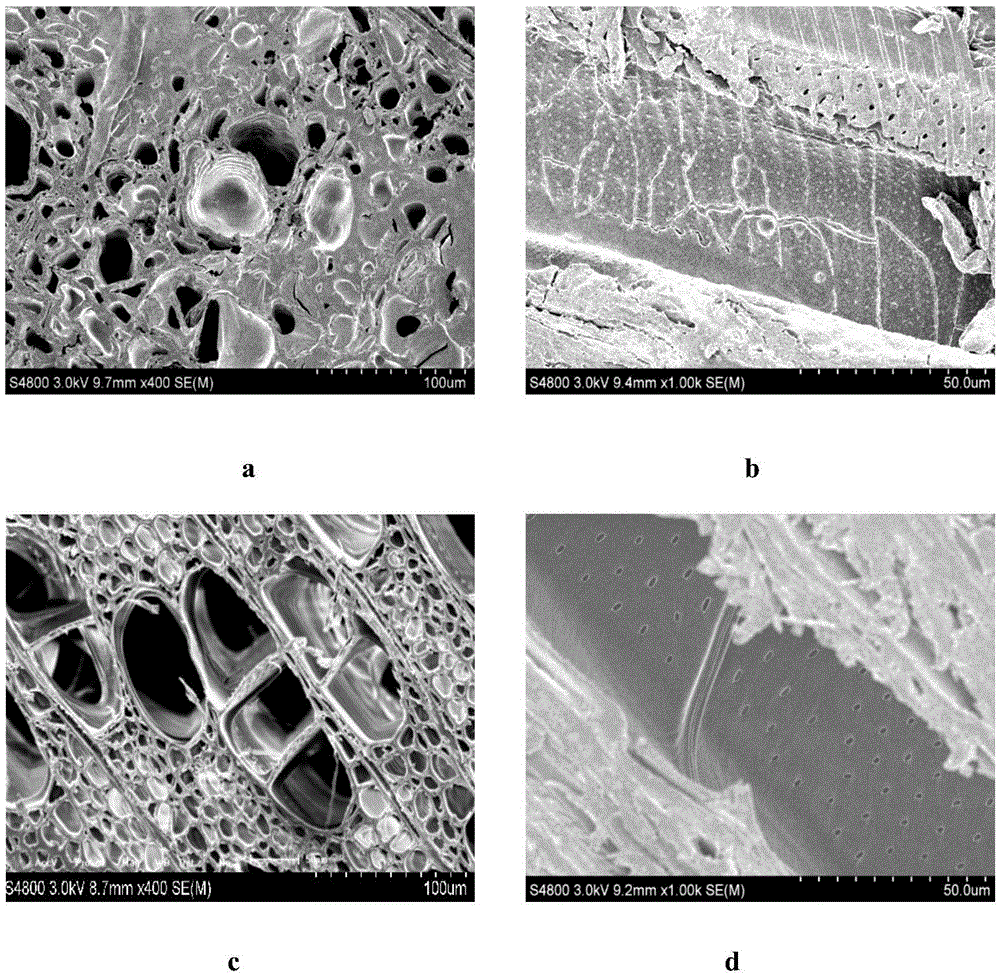

[0031] Use the size stabilization, antibacterial and insect-proof modifiers prepared by the present invention to modify the wood and bamboo materials and their products that are more permeable, and can adopt the mode of spraying and coating. Atmospheric pressure impregnation and vacuum pressure impregnation are used for 0.5-1.0 hours, and then through curing and drying to complete the dimensional stabilization, antibacterial and insect repellent treatment of wood and bamboo.

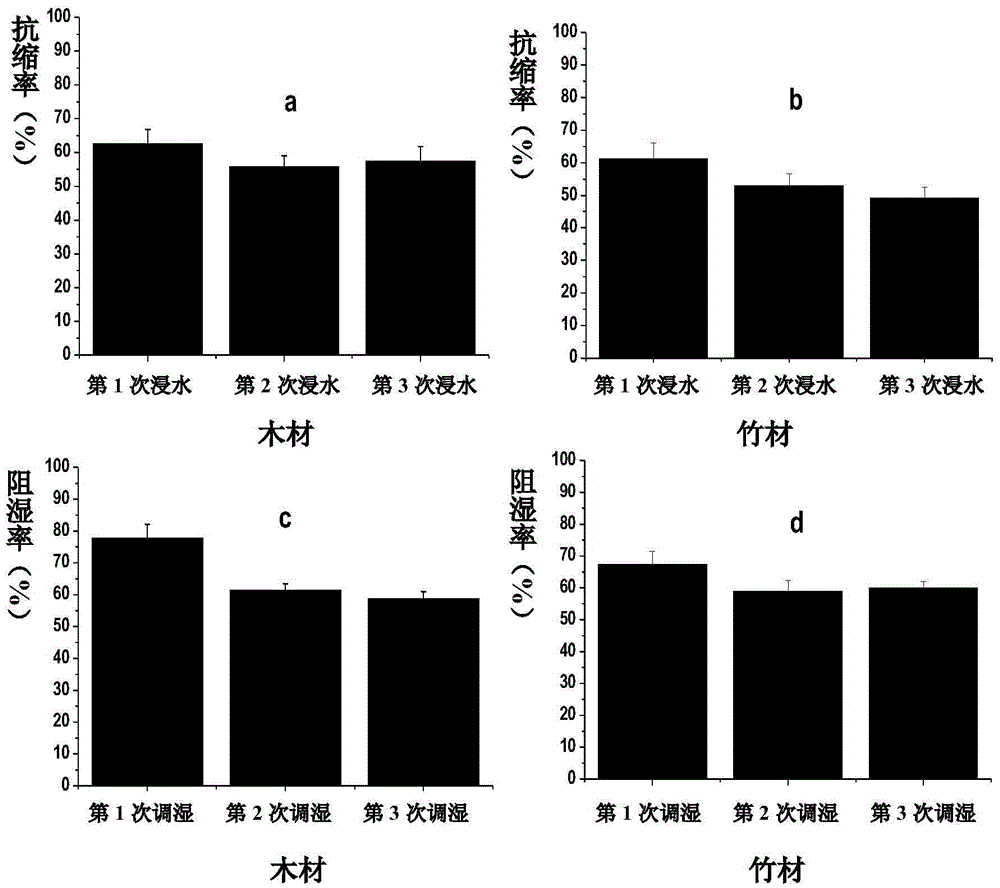

[0032] The anti-shrinkage rate of the treated material of the present invention reaches more than 40.0%, and the moisture resistance rate reaches m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com