Carbonized polydopamine coated cobalt nanoparticle material and preparation and application methods thereof

A technology of carbonized polydopamine and granular materials, applied in chemical instruments and methods, chemical/physical processes, oxidized water/sewage treatment, etc., can solve problems such as limiting the development process of high-efficiency catalysts, weakening or even ignoring contributions, and solve difficult separation Poor recovery and recycling, good economic and social benefits, and simple and easy-to-operate process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] With 100mL Tris-HCl buffer solution (pH=8.5) with a substance concentration of 10mmol / L as the dispersion medium, add 28.6mg of CoCl under stirring 2 ·6H 2 O, after the dissolution is complete, add 0.2g dopamine hydrochloride. After reacting for 6 hours, wash it centrifugally with distilled water (centrifugal speed 10000r / min, centrifugation time 10min), then vacuum dry the product at 80°C for 12 hours. Grind, place in a vacuum tube furnace and heat up to 800°C in a nitrogen atmosphere, the heating rate is 5°C / min, and keep warm for 2h to obtain the target product of the present invention, that is, a novel carbonized polydopamine-coated cobalt nanoparticle material (bifunctional polydopamine Derivative nitrogen-doped carbon-coated cobalt nanoparticle material).

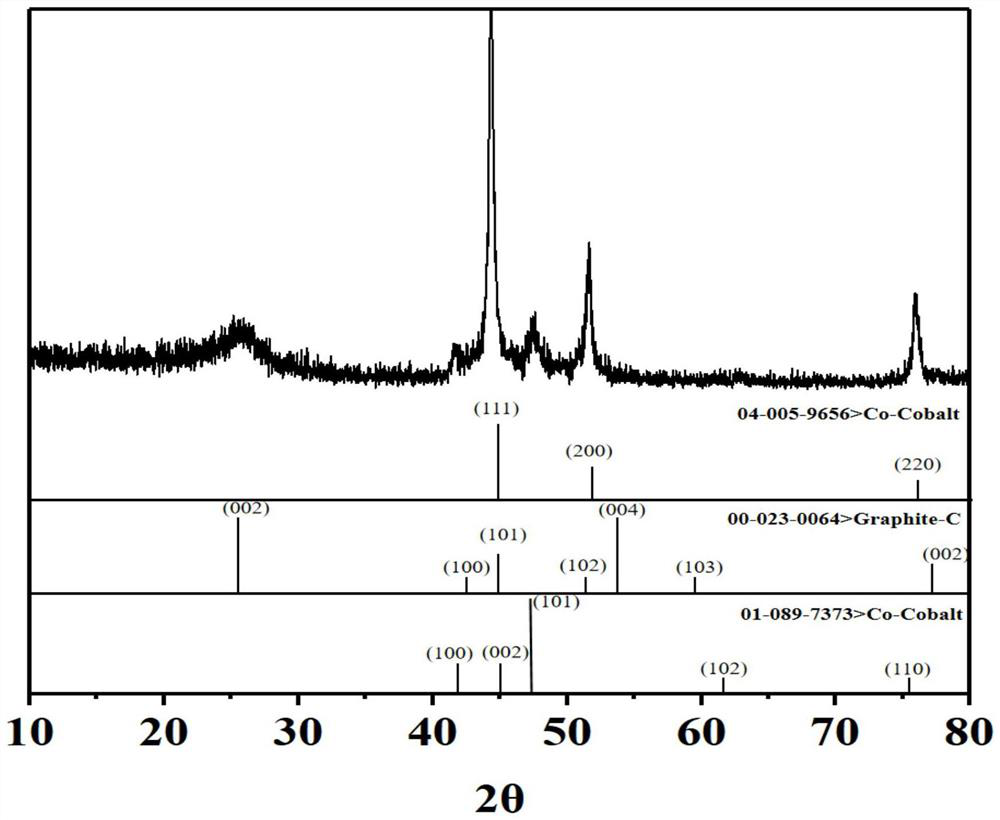

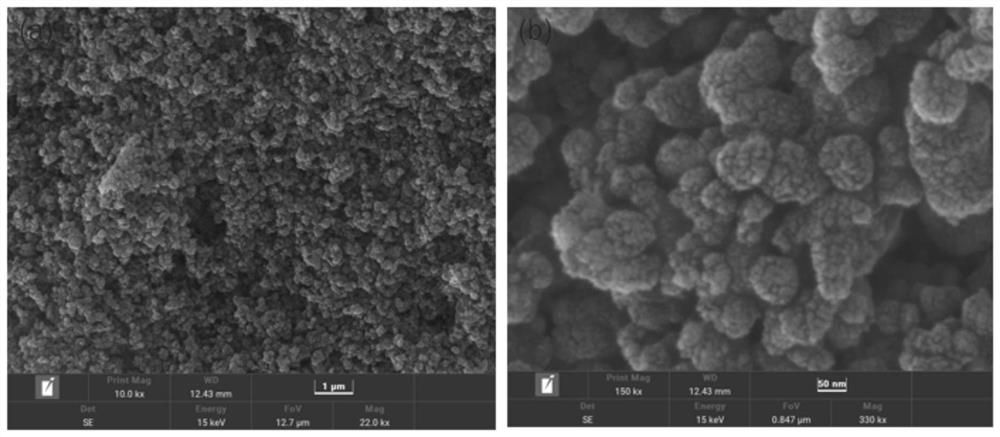

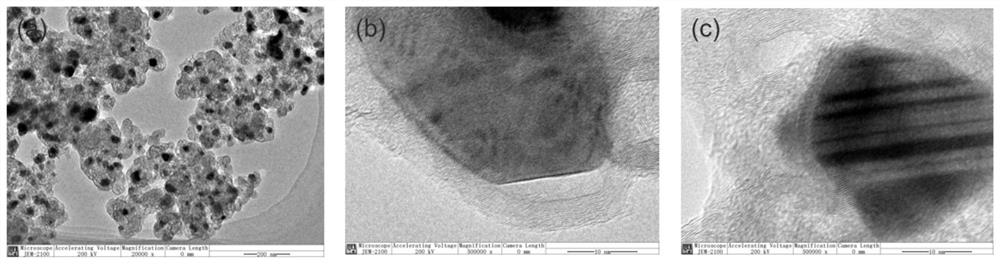

[0035] Depend on figure 1It can be seen from the XRD figure that the diffraction peaks presented by the materials prepared in this embodiment correspond to graphite carbon (PDF#00-023-0064), cubic cobalt crys...

Embodiment 2

[0040] With 100mL Tris-HCl buffer solution (pH=8.5) with a substance concentration of 10mmol / L as the dispersion medium, add 28.6mg of CoCl under stirring 2 ·6H 2 O, after the dissolution is complete, add 0.2g dopamine hydrochloride. After reacting for 6 hours, after centrifugation and washing with distilled water (centrifugal speed 15000r / min, centrifugation time 5min), the product is vacuum-dried at 60°C for 24 hours. After drying, pass through an agate mortar Grind, place in a vacuum tube furnace and heat up to 1000°C in a helium atmosphere, the heating rate is 1°C / min, and keep warm for 1h to obtain the target product of the present invention, that is, a novel carbonized polydopamine-coated cobalt nanoparticle material (bifunctional polydopamine Dopamine-derived nitrogen-doped carbon-coated cobalt nanoparticle material).

[0041] Novel carbonized polydopamine-coated cobalt nanoparticles for catalytic activation of persulfate to degrade bisphenol A in wastewater: 15 mg of ...

Embodiment 3

[0043] With 100mL Tris-HCl buffer solution (pH=8.5) with a substance concentration of 10mmol / L as the dispersion medium, add 42.9mg of CoCl under stirring 2 ·6H 2 O, after the dissolution is complete, add 0.2g dopamine hydrochloride. After reacting for 4 hours, after centrifugation and washing with distilled water (centrifugation speed 12000r / min, centrifugation time 8min), the product is vacuum-dried at 100°C for 12 hours. Grind, place in a vacuum tube furnace and heat up to 700°C in an argon atmosphere with a heating rate of 3°C / min, and keep warm for 3h to obtain the target product, which is a new carbonized polydopamine-coated cobalt nanoparticle material (bifunctional polydopamine-derived nitrogen doped carbon-coated cobalt nanoparticle material).

[0044] The new carbonized polydopamine-coated cobalt nanoparticle material prepared in this example is used to catalyze the activation of persulfate to degrade diclofenac in wastewater: 15 mg of bifunctional polydopamine-deri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com