A kind of environmentally friendly structural water-based intumescent fireproof coating and preparation method thereof

A kind of fire-resistant coating, environment-friendly technology, applied in the direction of fire-resistant coatings, coatings, etc., can solve the problems of high cost, no application value, etc., achieve low cost, excellent fire-proof effect, and improve the effect of fire-proof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

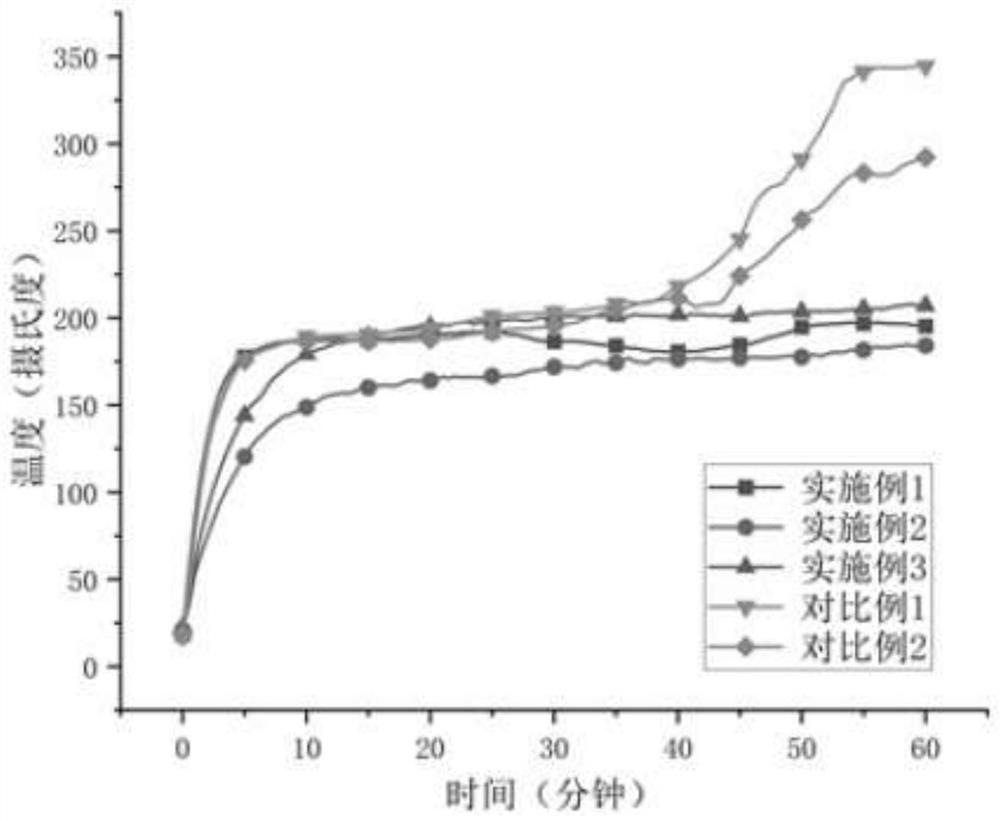

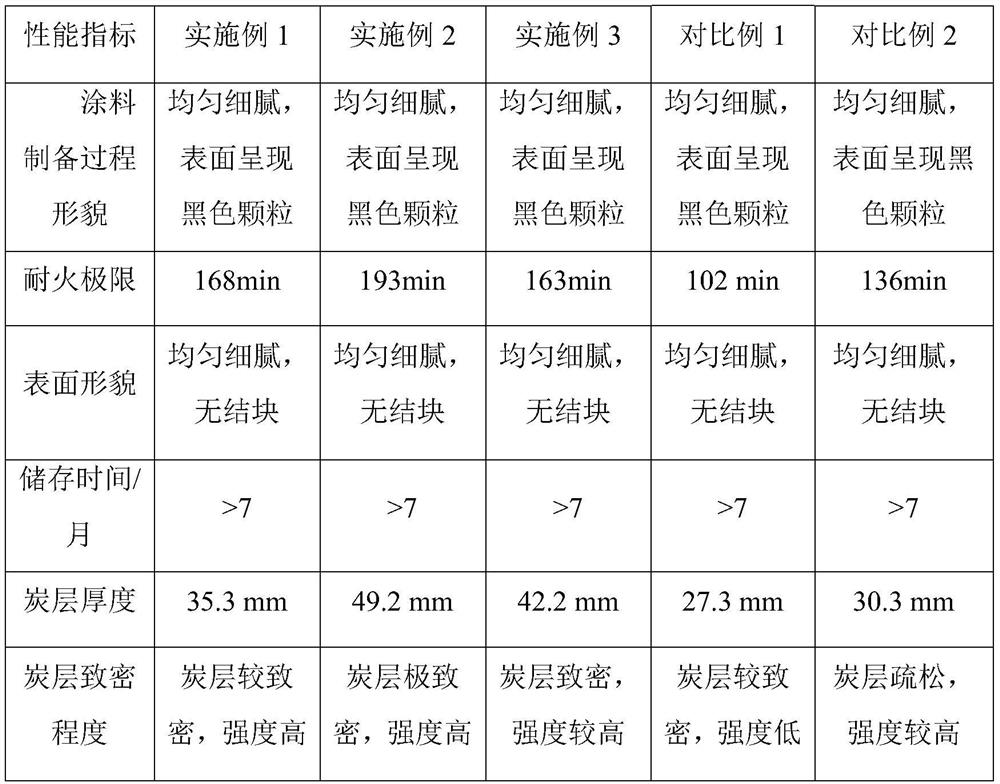

Embodiment 1

[0052] An environmentally friendly structural water-based intumescent fireproof coating, the components and their mass percentages are: acrylate core-shell emulsion 20%, MFAPP 32%, expandable graphite 24%, ascorbic acid 3.5%, sepiolite powder 6.5% , hydroxyethyl cellulose 0.5%, dispersant 0.5%, defoamer 0.5%, n-octanol 0.5%, water 12%; Its preparation method comprises the following steps:

[0053] 1) Weigh the raw materials according to the above proportioning requirements;

[0054] 2) Grind the weighed MFAPP, expandable graphite, ascorbic acid, hydroxyethyl cellulose, and sepiolite powder until there are no particles, then add water to fully grind and mix evenly; then add defoamer and dispersant, and continue to grind fully;

[0055] 3) Finally, the acrylate core-shell emulsion and n-octanol are added and thoroughly ground and mixed to obtain the fireproof coating.

Embodiment 2

[0057] A water-based expansion type fireproof coating, its preparation method is roughly the same as that of Example 1, the difference is that each component and its mass percentage are: acrylate core-shell emulsion 20%, MFAPP 32%, expandable graphite 24%, Ascorbic acid 5%, sepiolite powder 5%, hydroxyethyl cellulose 0.5%, dispersant 0.5%, defoamer 0.5%, n-octanol 0.5%, water 12%.

Embodiment 3

[0059] A water-based expansion type fireproof coating, its preparation method is roughly the same as that of Example 1, the difference is that each component and its mass percentage are: acrylate core-shell emulsion 20%, MFAPP 32%, expandable graphite 24%, Ascorbic acid 6.5%, sepiolite powder 3.5%, hydroxyethyl cellulose 0.5%, dispersant 0.5%, defoamer 0.5%, n-octanol 0.5%, water 12%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com