Preparation method of oxide-coated double-element co-doped high-nickel ternary positive electrode material

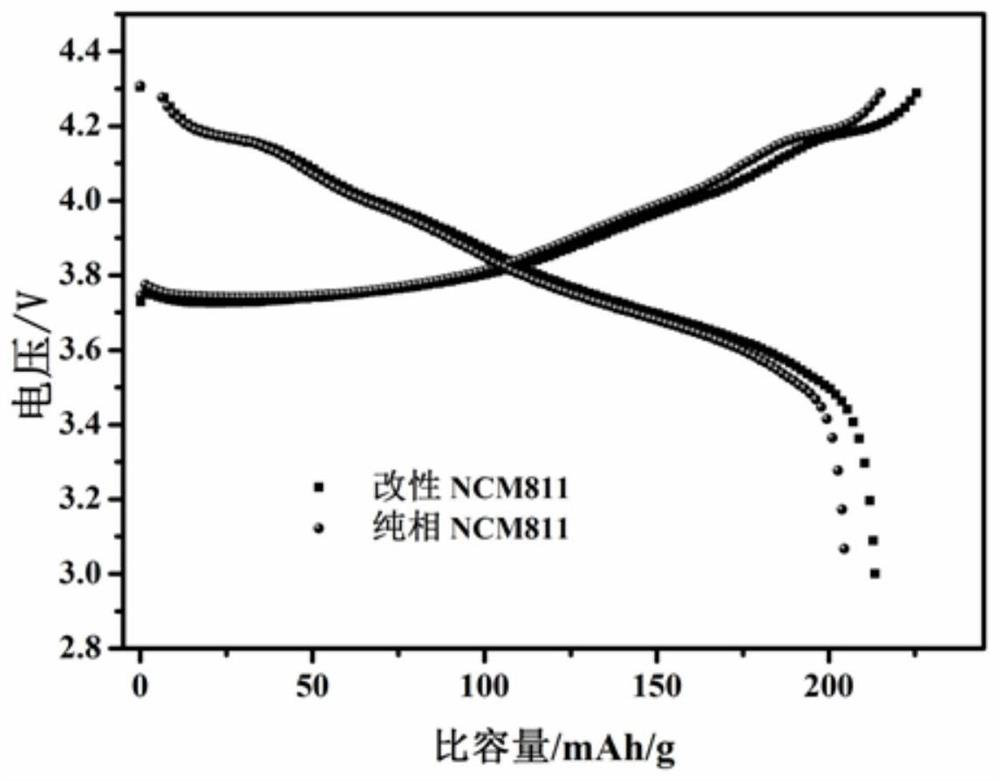

A technology of high-nickel ternary materials and positive electrode materials, applied in the direction of positive electrodes, active material electrodes, electrical components, etc., can solve the problems of unstable structure, easy water absorption of high-nickel materials, and unsatisfactory cycle performance, so as to avoid direct contact , the improvement of gram capacity reduction, the effect of improving capacity retention and cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

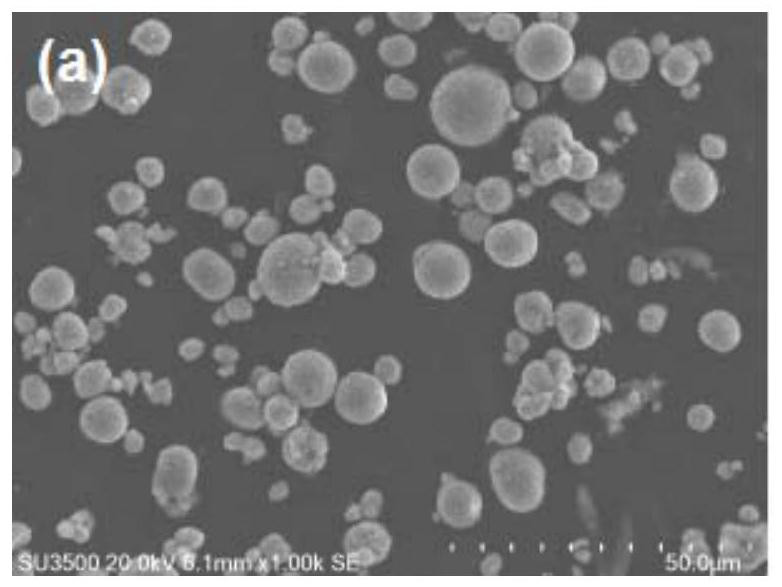

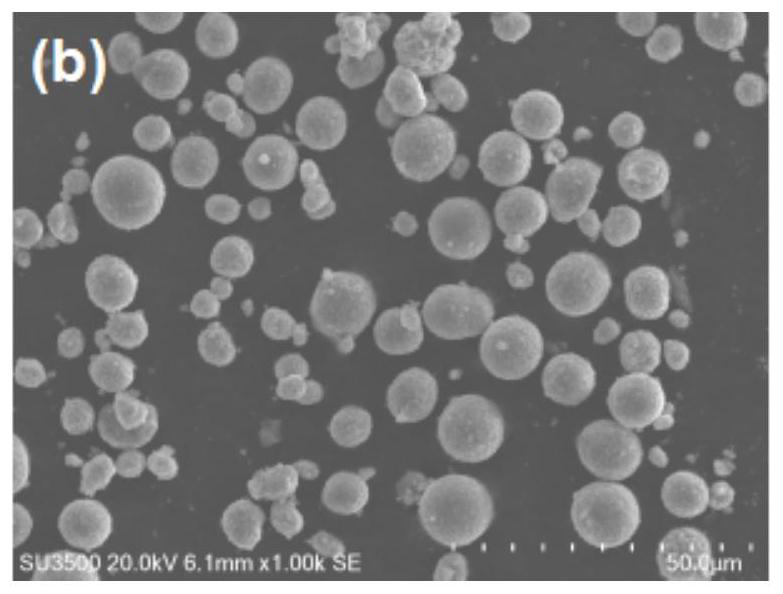

[0028] A method for preparing a titanium oxide-coated magnesium-niobium co-doped high-nickel ternary positive electrode material, specifically comprising the following steps:

[0029] (1), 5.0g Ni 0.8 co 0.1 mn 0.1 (OH) 2 The precursor is dispersed in ethanol, adding 0.005gMgCl 2 , 0.005gNbCl 5 Mix with LiOH and dry at 100°C;

[0030] (2) Put the dried material obtained in step (1) into an oxygen atmosphere for calcination, first raise the temperature to 480°C at a rate of 5°C / min, heat at a constant temperature for 5 hours, and then raise the temperature to 750°C at a rate of 5°C / min , heated at constant temperature for 15h, to obtain magnesium-niobium co-doped Li[Ni 0.8 co 0.1 mn 0.1 ]O 2 , where the doped mass of magnesium and niobium accounted for Li[Ni 0.8 co 0.1 mn 0.1 ]O 2 0.1% of mass;

[0031] (3), disperse 0.0235g tetraethyl titanate into 31.5mL ethanol, then add 5.0g magnesium-niobium co-doped Li[Ni 0.8 co 0.1 mn 0.1 ]O 2 Powder and 5mL deionized w...

Embodiment 2

[0036] A method for preparing an aluminum oxide-coated indium-niobium co-doped high-nickel ternary positive electrode material, specifically comprising the following steps:

[0037] (1), 5.0g Ni 0.8 co 0.1 mn 0.1 (OH) 2 The precursor is dispersed in ethanol, adding 0.005g InCl 3 , 0.01gNbCl 5 and Li 2 CO 3 Mix well and dry at 100°C;

[0038] (2) Put the dried material obtained in step (1) into an oxygen atmosphere for calcination, first raise the temperature to 600°C at a rate of 3°C / min, heat at a constant temperature for 6 hours, and then raise the temperature to 600°C at a rate of 4°C / min , heated at constant temperature for 18h, to obtain indium-niobium co-doped Li[Ni 0.8 co 0.1 mn 0.1 ]O 2 , where the mass of indium and niobium doping accounts for Li[Ni 0.8 co 0.1 mn 0.1 ]O 2 0.1% and 0.2% of mass;

[0039] (3) Disperse 0.033g of aluminum isopropoxide into 31.5mL of ethanol, then add 5.0g of indium and niobium co-doped Li[Ni 0.8 co 0.1 mn 0.1 ]O 2 Powd...

Embodiment 3

[0041] A method for preparing an iron oxide-coated magnesium-aluminum co-doped high-nickel ternary positive electrode material, specifically comprising the following steps:

[0042] (1), 5.0g Ni 0.8 co 0.1 mn 0.1 (OH) 2 Precursor dispersed in ethanol, adding 0.01g MgCl 2 , 0.005gAlCl 3 and Li 2 CO 3 Mix well and dry at 100°C;

[0043] (2) Put the dried material obtained in step (1) into an oxygen atmosphere for calcination, first raise the temperature to 400°C at a rate of 6°C / min, heat at a constant temperature for 3 hours, and then raise the temperature to 700°C at a rate of 3°C / min , heated at constant temperature for 12h, and magnesium-aluminum co-doped Li[Ni 0.8 co 0.1 mn 0.1 ]O 2 , where the doped mass of Mg and Al accounts for Li[Ni 0.8 co 0.1 mn 0.1 ]O 2 0.2% and 0.1% of mass;

[0044] (3), disperse 0.04g ferric citrate in 40mL ethanol, then add 5.0g magnesium-aluminum co-doped Li[Ni 0.8 co 0.1 mn 0.1 ]O 2 Powder and 7.5mL of deionized water to make...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com