Method for producing titanium tetrachloride through high-efficiency long-period operation of boiling chlorination system

A technology for the production of titanium tetrachloride and chlorination systems, applied in the direction of titanium tetrachloride and titanium halides, can solve the problem of difficult control of the temperature and pressure of the boiling chlorination furnace, affecting the long-term operation of the boiling chlorination furnace, and deteriorating the boiling flow To reduce the probability of impurity deposition, increase output and production efficiency, and increase gas velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

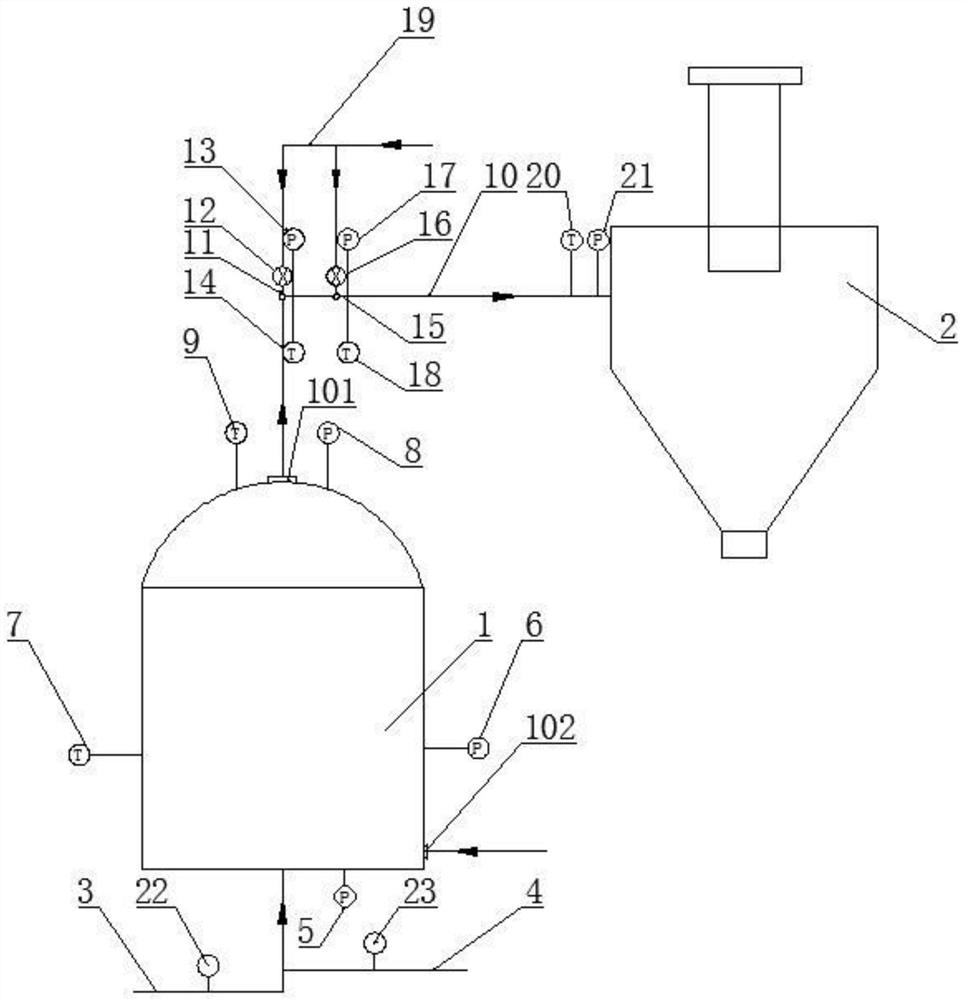

[0029] (1) As shown in the figure, adopt boiling chlorination to produce titanium tetrachloride system, comprise boiling chlorination furnace 1 and cyclone separator 2, the diameter of the boiling chlorination furnace that uses in the present embodiment is 5m, height is 13 meters , on the gas inlet pipeline at the bottom of the fluidized chlorination furnace 1, a chlorine gas inlet pipe 3 and an oxygen inlet pipe 4 are respectively connected, a chlorine gas flowmeter 22 is installed on the chlorine gas inlet pipe 3, and an oxygen flowmeter 23 is installed on the oxygen inlet pipe 4 Bottom pressure gauge 5 is arranged at the bottom of the boiling chlorination furnace 1, reaction section pressure gauge 6 and infrared thermometer 7 are arranged at the reaction section of boiling chlorination furnace 1, and a pressure gauge 5 is arranged at the top of the boiling chlorination furnace 1 tower A tower top pressure gauge 8 and a tower top thermocouple 9 are provided with a charge inle...

Embodiment 2

[0038] (1) As shown in the figure, adopt boiling chlorination to produce titanium tetrachloride system, comprise boiling chlorination furnace 1 and cyclone separator 2, the diameter of the boiling chlorination furnace that uses in the present embodiment is 5m, height is 13 meters , on the gas inlet pipeline at the bottom of the fluidized chlorination furnace 1, a chlorine gas inlet pipe 3 and an oxygen inlet pipe 4 are respectively connected, a chlorine gas flowmeter 22 is installed on the chlorine gas inlet pipe 3, and an oxygen flowmeter 23 is installed on the oxygen inlet pipe 4 Bottom pressure gauge 5 is arranged at the bottom of the boiling chlorination furnace 1, reaction section pressure gauge 6 and infrared thermometer 7 are arranged at the reaction section of boiling chlorination furnace 1, and a pressure gauge 5 is arranged at the top of the boiling chlorination furnace 1 tower A tower top pressure gauge 8 and a tower top thermocouple 9 are provided with a charge inle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com