Oxalyl dihydrazine nitrate metal complex suitable for solid propellant and preparation method of oxalyl dihydrazine nitrate metal complex

A technology of nitrate oxalyl dihydrazide and metal complex, which is applied in the preparation of hydrazide, nitrated acyclic/alicyclic/heterocyclic amine explosive compositions, attack equipment, etc., can solve the problem of poor safety performance and low self-energy level , the effect of improving the burning rate is not ideal, etc., to achieve the effect of good compatibility, high burning rate and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

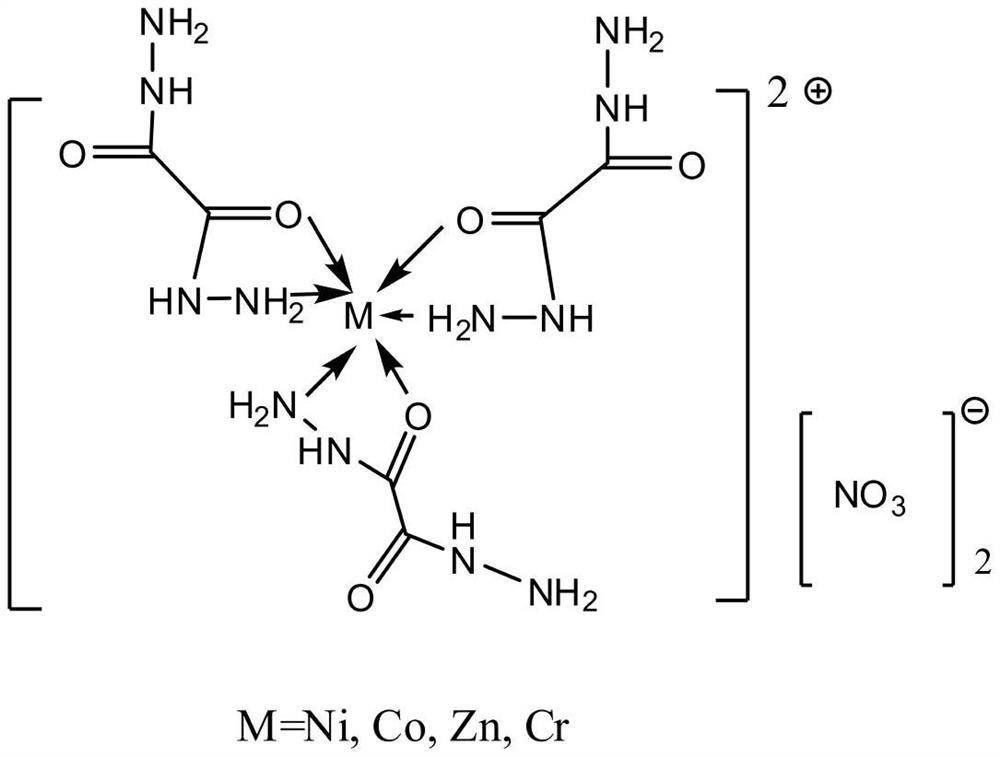

[0050] The application also provides a preparation method of a class of oxalyl dihydrazide metal complexes, comprising the following steps:

[0051] Step (1), dissolving oxalodihydrazide in distilled water, heating at 85-95°C until dissolved and transparent to obtain an oxalodihydrazide solution with a molar concentration of 0.20-1.50 mol / L, adding nitric acid to adjust the pH value to 5-6 , adding dropwise a metal nitrate aqueous solution with a molar concentration of 0.30 to 1.00 mol / L, the metal nitrate being at least one of nickel nitrate, zinc nitrate, cobalt nitrate or chromium nitrate crystal hydrate to obtain a reaction solution, in the reaction solution, The molar ratio of oxalyl dihydrazine to metal nitrate is 3:1~3:1.2, after the dropwise addition, keep it at 85~95°C for 30min~300min, cool down to obtain solid oxalyldihydrazine nitrate metal complex;

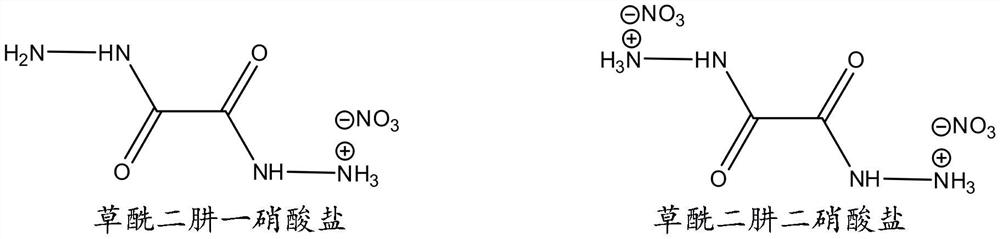

[0052] Step (2), dissolving the oxalyl dihydrazide metal complex obtained in (1) in a polar solvent, the polar solven...

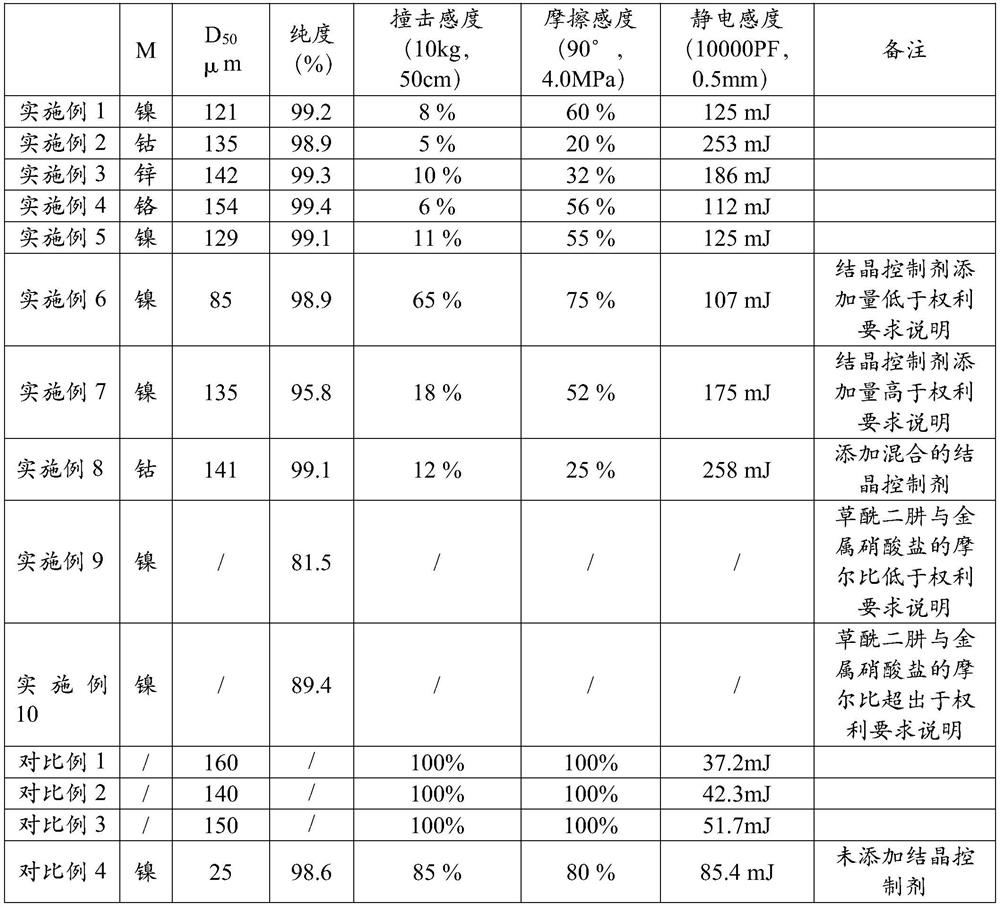

Embodiment 1

[0056] Dissolve 1.66g of oxalodihydrazide in 50ml of distilled water, heat to 85°C to dissolve and make it transparent, add dilute nitric acid dropwise to adjust the pH value to 5, add 15ml of 0.3mol / L nickel nitrate aqueous solution dropwise, and keep it at 85°C after the dropwise addition The reaction was continued for 30 minutes, and cooled naturally to obtain 4.62 g of nickel oxalyl dihydrazine nitrate complex with a purity of 96.4% and a yield of 61.2% as a light green solid.

[0057] Dissolve 4.62 g of nickel oxalyl dihydrazine nitrate obtained above in 25 g of methanol / water (volume ratio 3: 7) mixed solution, add 0.23 g of oxalyl dihydrazide mononitrate, and stir the mixed solution at 40°C for 15 min , step cooling, filter, get D 50 Nickel oxalodihydrazide nitrate with a thickness of about 121 μm has a purity of 99.2% and a final yield of 58.9%.

[0058] Characterization of nickel oxalyl dihydrazine nitrate:

[0059] Elemental analysis (Ni(C 2 N 4 h 6 o 2 ) 3 (N...

Embodiment 2

[0061] Dissolve 1.66g of oxalodihydrazine in 10ml of distilled water, heat to 90°C to dissolve and make it transparent, add dilute nitric acid dropwise to adjust the pH value to 6, add 9ml of 0.5mol / L cobalt nitrate aqueous solution dropwise, and keep at 90°C after the dropwise addition is completed After reacting for 60 minutes and cooling naturally, 4.45 g of cobalt oxalodihydrazine nitrate solid was obtained, with a purity of 97.3% and a yield of 58.9%.

[0062] Dissolve 4.45 g of cobalt oxalyl dihydrazine nitrate obtained above in 28 g of methanol / water (volume ratio 4: 6) mixed solution, add 0.36 g of oxalyl dihydrazide dinitrate, and stir the mixed solution at 50° C. for 30 min , step cooling, filter, get D 50 The cobalt oxalyl dihydrazide nitrate is about 135 μm in size, the purity of the cobalt oxalyl dihydrazide nitrate is 98.9%, and the final yield is 56.6%.

[0063] Characterization of cobalt oxalyl dihydrazine nitrate:

[0064] Elemental analysis (Co(C 2 N 4 h ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com