Strengthening and toughening regulation and control method for refractory high-entropy alloy

A high-entropy alloy, strengthening and toughening technology, which is applied in the field of strengthening and toughening of refractory high-entropy alloys, can solve the problems of ignoring alloy characteristics and few reports on alloying element control, and achieve comprehensive mechanical properties and excellent high-temperature microstructure. Effects of structural stability, high strength and plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

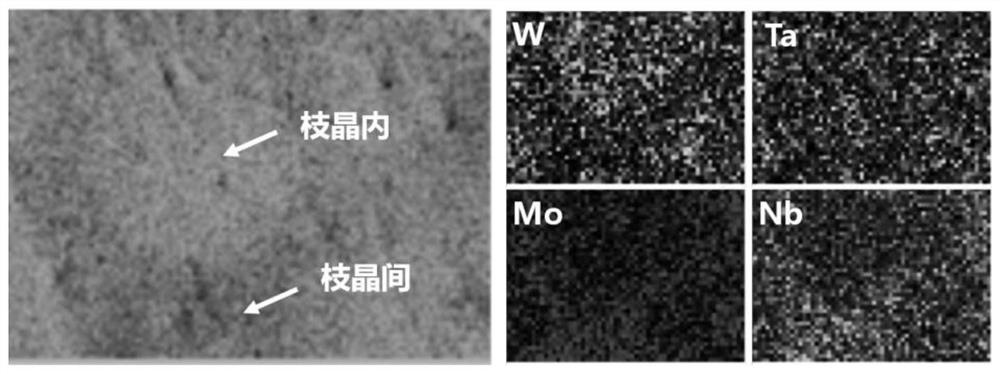

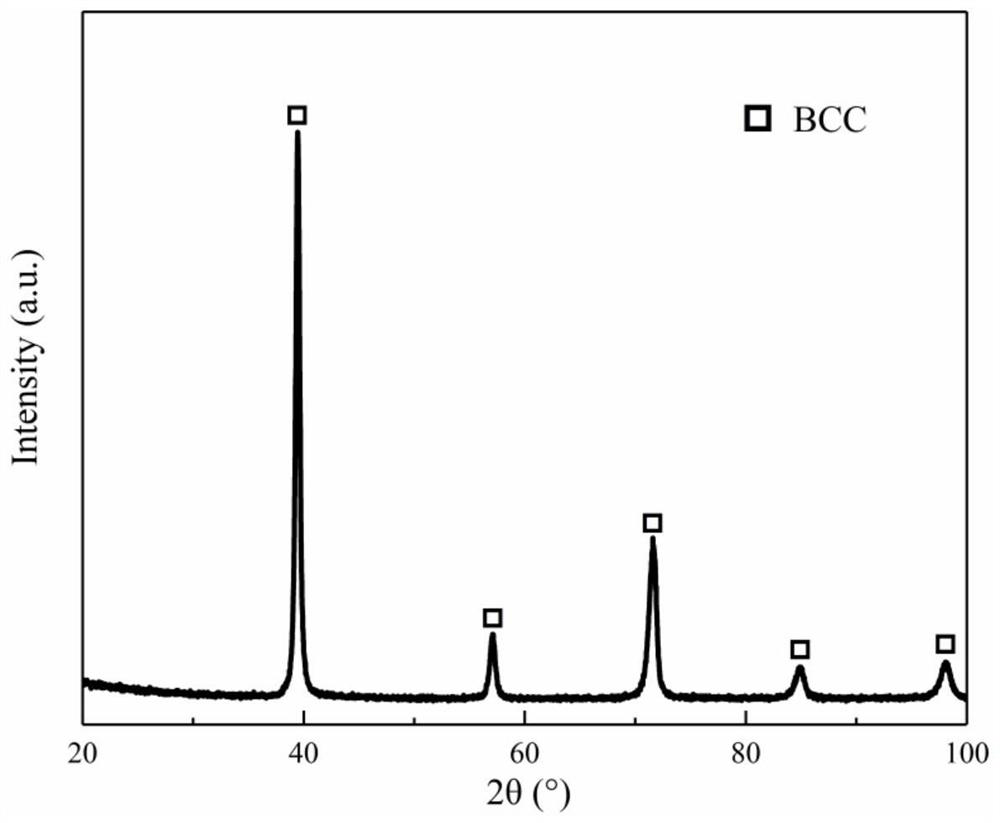

[0027] (1) Take W, Ta, Mo, Nb elemental pure metal particles with a purity of not less than 99.95wt.%, mechanically polish to remove scale, and after ultrasonic cleaning and drying, according to the atomic ratio of 25at.%W-25at.%Ta- 25at.% Mo-25at.% Nb for precise batching. The weighed 4 kinds of pure metal raw materials are successively distributed in the water-cooled copper mold crucible of the non-consumable vacuum arc melting furnace according to the order of the melting point of the elements from low to high. Vacuum the chamber to 4×10 before melting -3 Pa, filled with argon to 0.7 atmospheres. When smelting, first smelt the titanium ingot in the furnace for 3 minutes to remove the residual oxygen in the furnace cavity; when smelting the target alloy, keep it for 150s after the alloy is completely melted, then cool, turn the alloy ingot and melt again, a total of 6 melting times to ensure that the alloy composition is uniform .

[0028] (2) A block sample of 5 mm × 4 m...

Embodiment 2

[0034] On the basis of Example 1, different from Example 1: in step (2), the element content is optimized to W 10 Ta 10 Mo 40 Nb 40 . In step (3), W, Ta, Mo, Nb elemental pure metal particles with a purity of not less than 99.95wt.% are taken, mechanically polished to remove scale, and after ultrasonic cleaning and drying, the atomic ratio is 10at.%W-10at. %Ta-40at.%Mo-40at.%Nb for precise batching. In step (4), utilize wire cutting to cut from the middle part of the alloy ingot Use 2000-grit sandpaper to gently grind off the wire-cut marks on the bottom surface of the cylindrical sample and the scale on the side. After ultrasonic cleaning and drying, use the Instron5982 electronic universal testing machine to test the mechanical properties of the alloy at room temperature.

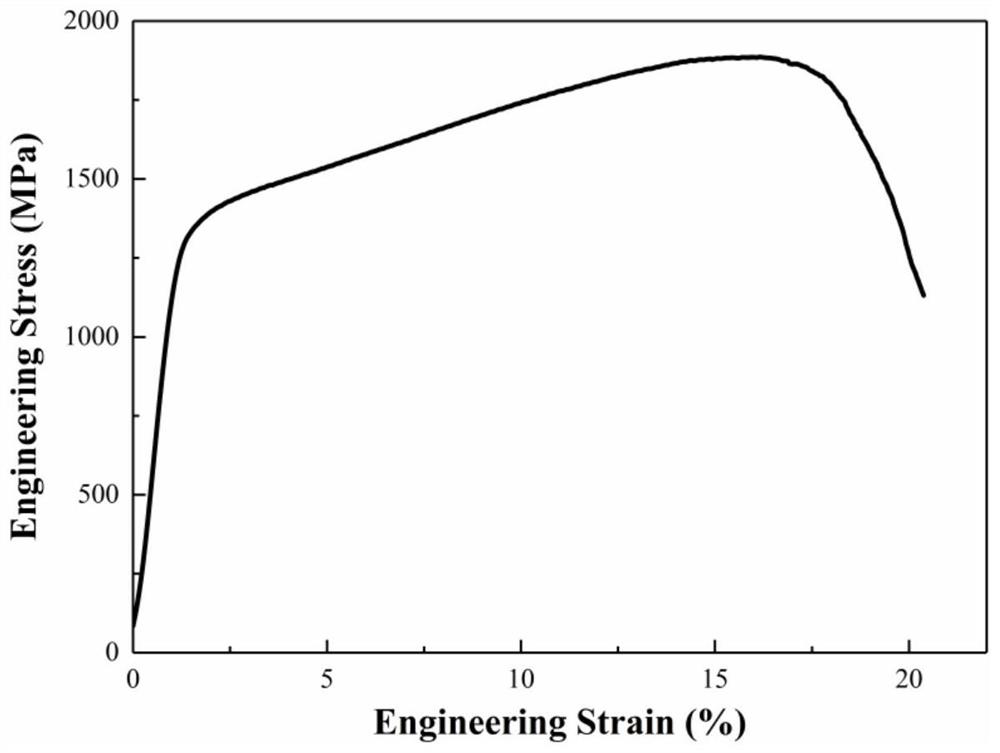

[0035] image 3 W prepared for Example 2 10 Ta 10 Mo 40 Nb 40 Room temperature stress-strain curves of refractory high-entropy alloys. It can be seen that W 10 Ta 10 Mo 40 Nb 40 The yield ...

Embodiment 3

[0037] On the basis of Example 1, different from Example 1: in step (2), the element content is optimized to W 5 Ta 5 Mo 45 Nb 45 . In step (3), W, Ta, Mo, Nb elemental pure metal particles with a purity of not less than 99.95wt.% are taken, mechanically polished to remove scale, ultrasonically cleaned and dried, and the atomic ratio is 5at.%W-5at. %Ta-45at.%Mo-45at.%Nb for precise batching. In step (4), utilize wire cutting to cut from the middle part of the alloy ingot Use 2000-grit sandpaper to gently grind off the wire-cut marks on the bottom surface of the cylindrical sample and the scale on the side. After ultrasonic cleaning and drying, use the Instron5982 electronic universal testing machine to test the mechanical properties of the alloy at room temperature.

[0038] The W prepared in embodiment 3 5 Ta 5 Mo 45 Nb 45 The scanning electron microscope photos of refractory high-entropy alloys are attached Figure 4 shown. It can be seen that the optimized W 5 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com