High-temperature-resistant and high-voltage-resistant composite lithium cobalt oxide positive electrode material as well as preparation method and application thereof

A technology of compounding lithium cobalt oxide and positive electrode material, applied in the direction of positive electrode, battery electrode, active material electrode, etc., can solve the problems of large residual stress, adverse side reaction, interface instability, etc., and achieve good market use prospects and volume. Energy density advantage, the effect of improving interface stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

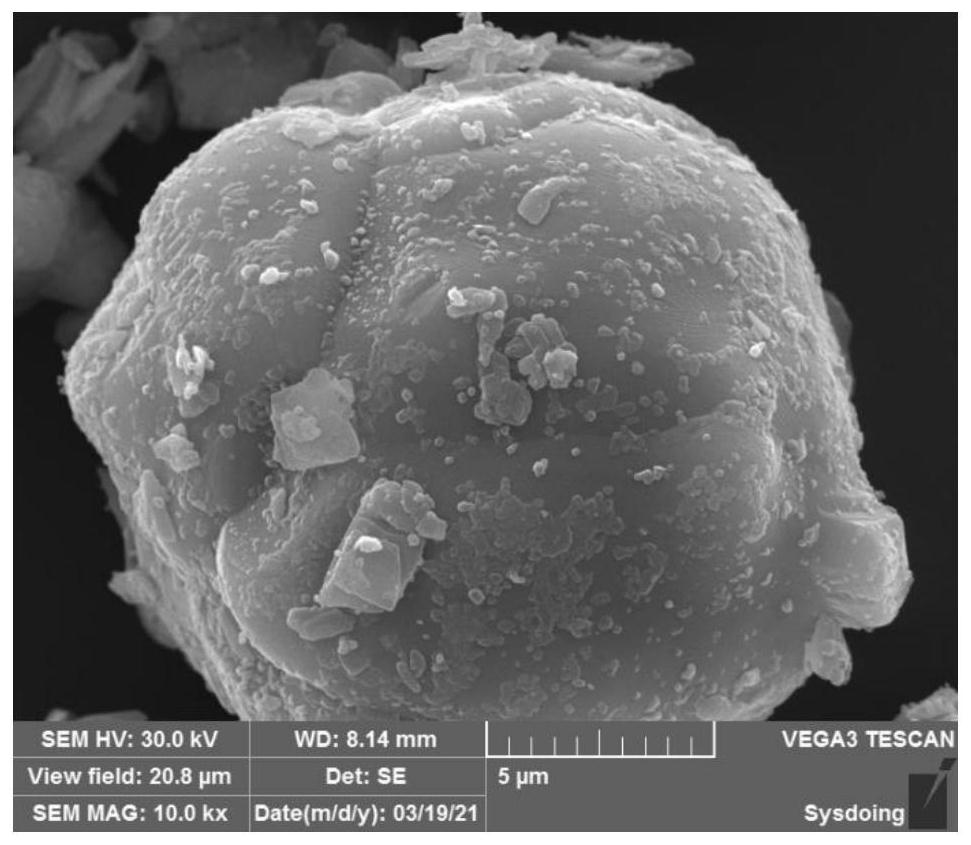

[0043] A method for preparing a high-temperature-resistant and high-voltage lithium cobalt oxide positive electrode material, comprising the steps of:

[0044] S100, mixing aluminum sulfate and cobalt sulfate solution, and carrying out co-precipitation reaction by controlling the addition of ammonium bicarbonate solution, and after the reaction is completed, the precipitate is separated, washed, and dried;

[0045] S200, mixing and ball-milling the product obtained in S100 with nano-alumina, then heating up to 600°C at a rate of 5°C / min for calcination, and the calcination time is 5h, to obtain a precursor of aluminum-doped cobalt tetroxide;

[0046] S300. Mix the precursor of cobalt tetroxide doped with aluminum element and the lithium source evenly, and heat up to 1000°C at a rate of 5°C / min for calcination. The calcination time is 12h. The calcination can be carried out in a box furnace and wait to be cooled. Afterwards, crushing and screening are carried out to obtain lith...

Embodiment 2

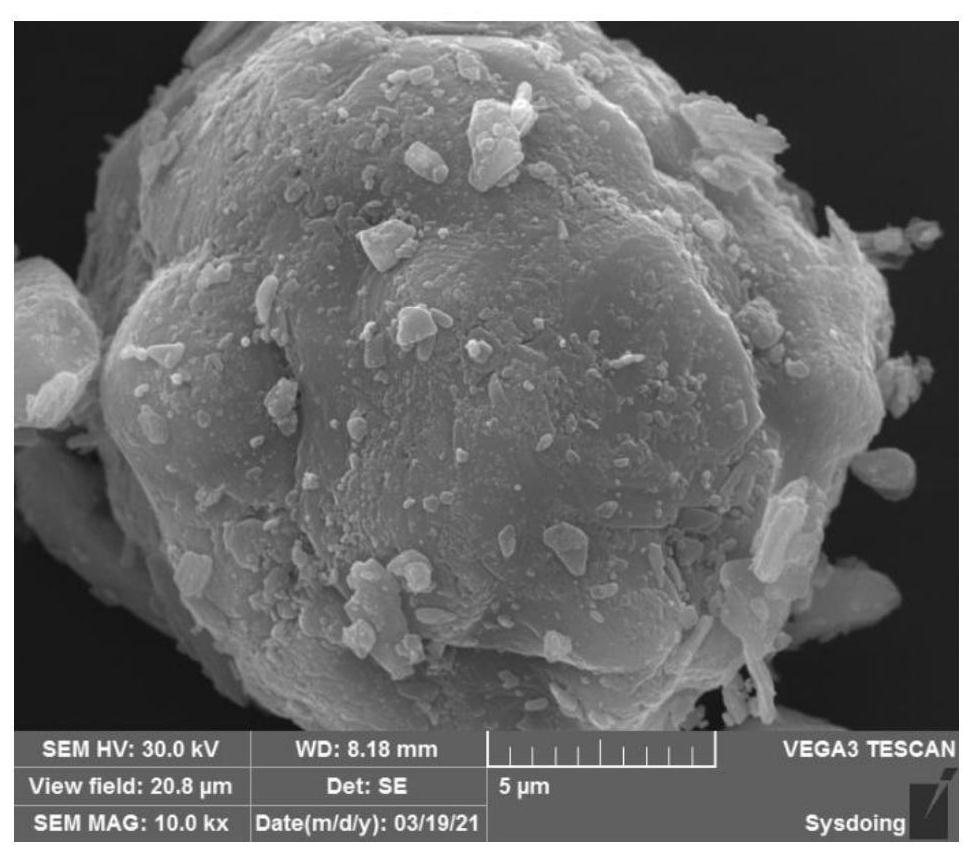

[0052] A method for preparing a high-temperature-resistant and high-voltage lithium cobalt oxide positive electrode material, comprising the steps of:

[0053] S100, mixing the aluminum sulfate and the cobalt sulfate solution, and carrying out the co-precipitation reaction by controlling the addition of the ammonium bicarbonate solution, and after the reaction is completed, the precipitate is separated, washed, and dried;

[0054] S200, mixing and ball-milling the product obtained in S100 with nano-alumina, then heating up to 600°C at a rate of 5°C / min for calcination, and the calcination time is 5h, to obtain a precursor of aluminum-doped cobalt tetroxide;

[0055] S300. Mix the precursor of cobalt tetroxide doped with aluminum element and the lithium source evenly, and heat up to 1000°C at a rate of 5°C / min for calcination. The calcination time is 12h. The calcination can be carried out in a box furnace and wait to be cooled. Afterwards, crushing and screening are carried ou...

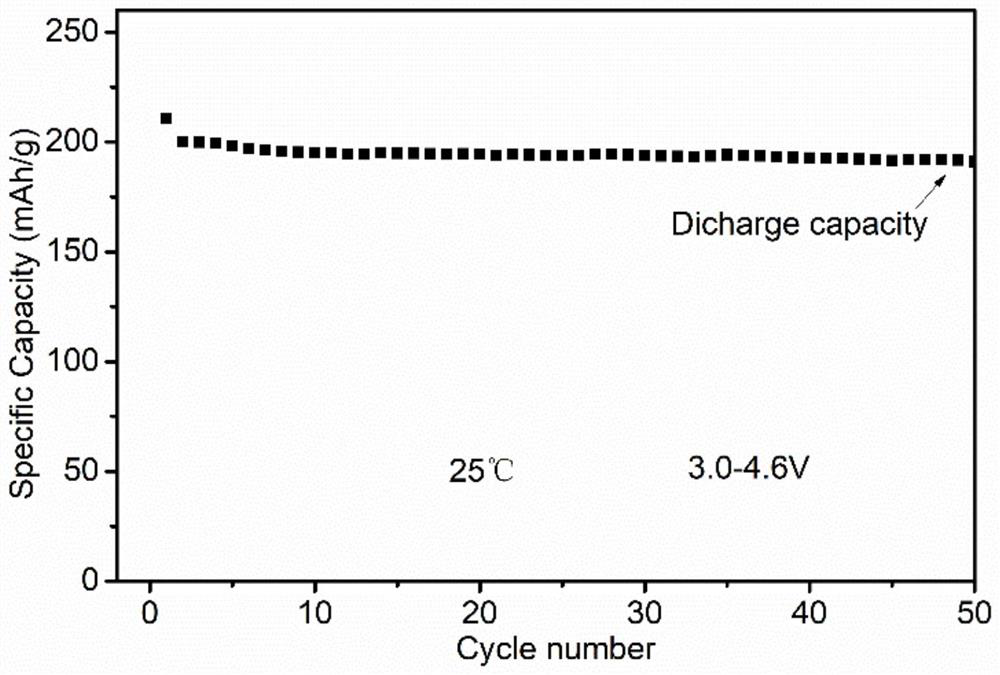

Embodiment 3

[0060] A method for preparing a high-temperature-resistant and high-voltage lithium cobalt oxide positive electrode material, comprising the steps of:

[0061] S100. Mix magnesium sulfate, aluminum sulfate and cobalt sulfate solution, and carry out co-precipitation reaction by controlling the addition of ammonium bicarbonate solution. After the reaction is completed, separate the precipitate, wash and dry;

[0062] S200, mixing and ball-milling the product obtained in S100 with aluminum oxide and magnesium oxide, and then heating up to 600°C at a rate of 5°C / min for calcination, and the calcination time is 5h, to obtain magnesium and aluminum multi-element co-doped tricobalt tetroxide Precursor;

[0063] S300. Mix the precursor of tricobalt tetroxide co-doped with magnesium and aluminum multi-element and lithium source evenly, and heat up to 1000°C at a rate of 5°C / min for calcination. The calcination time is 12h. The calcination can be placed in a box furnace. Carry out, aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com