Fiber composite material container main body part and manufacturing method thereof

A technology of fiber composite materials and manufacturing methods, applied in the field of textiles, can solve the problems affecting the cost of long-distance full-load or empty-load transportation, the inability to realize integral molding, and cumbersome production process, so as to save painting and repair, maintain permanent, reduce The effect of shipping costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

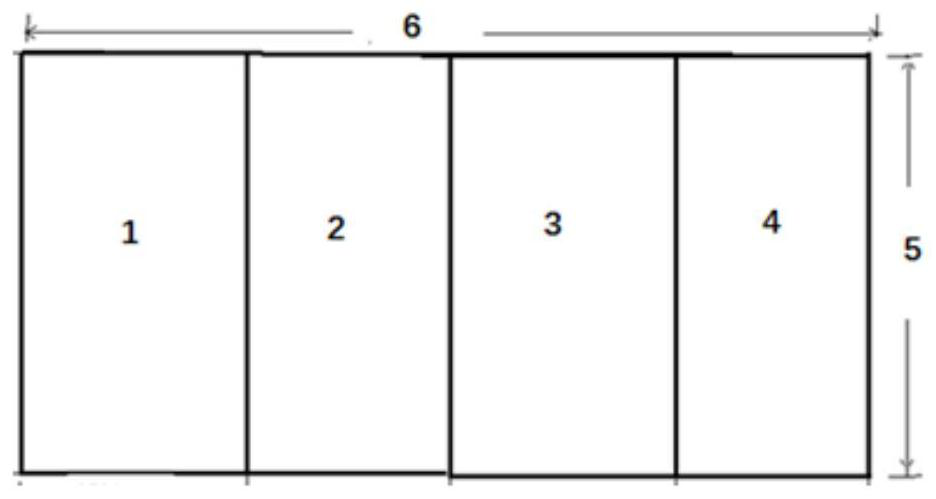

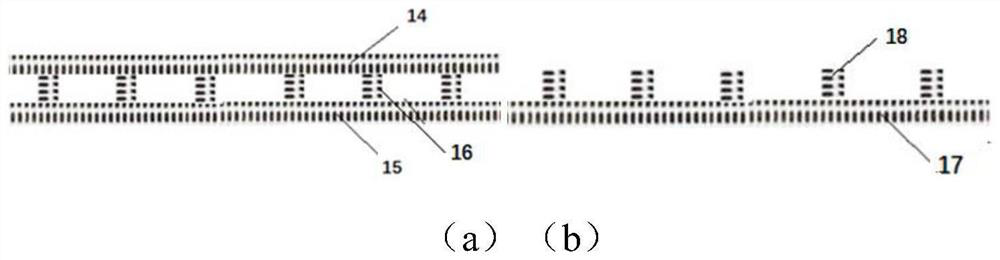

[0056] In this embodiment, carbon fiber and high-strength polyester filaments are used as raw materials to weave the core layer reinforcement of the "I" cross-section with double rapier looms. The profile fabric of the "I" cross-section is made of two independent The weft insertion system inserts the weft, and the warp yarns of the upper and lower layers are interwoven three-dimensionally with the warp yarns of the upper and lower layers to form a face-to-face double-layer fabric.

[0057] Impregnate with polytetrafluoroethylene dispersed emulsion, and externally coat polytetrafluoroethylene dispersed emulsion to make the main part of a 20-foot container red container.

[0058] (1) T300 (5000dtex) carbon fiber filaments are selected as the warp and weft yarns of the upper and lower fabrics of the core layer, and 3000dtex high-strength polyester filaments are used as the warp yarns. The fabric density: warp density 60 / 10cm, weft density 60 / 10cm, The fabric spacing is 6mm.

[0...

Embodiment 2

[0068] In this example, carbon fiber filaments and glass fiber filaments are used as raw materials to weave a core layer reinforcement with a warp knitting machine, impregnated with polytetrafluoroethylene dispersion emulsion, and coated with polytetrafluoroethylene dispersion emulsion to make a 40-foot container black container body part.

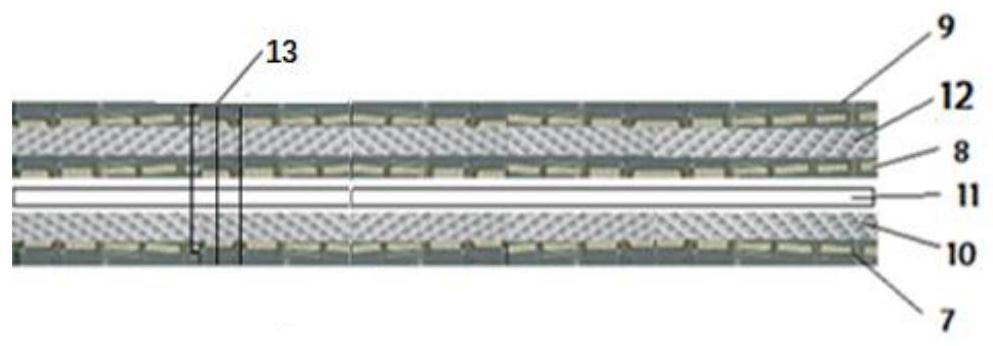

[0069] (1) Select 48K large tow carbon fiber to lay 90° yarn layers 7, 8, 9 and 0° yarn layers 11, select 5000dtex glass fiber filaments to lay +45° yarn layers 10, -45° yarn layers 12, Select 500dtex nylon filaments as the binding yarn 13, and bind the above-mentioned 6 layers of yarn layers into a core layer. Yarn quality of each layer is 80-700g / m 2 , The yarns in the same layer are equally spaced at intervals of 0.5-2mm.

[0070] The speed of the knitting machine is 2m / min. The width of the core layer is 7.3m.

[0071] Core layer shaping process conditions: speed 5m / min, shaping temperature 340°C.

[0072] (2) The technological pr...

Embodiment 3

[0077] This embodiment is to use carbon fiber, high temperature filter bag to recycle regenerated fiber yarn, carbon fiber chopped fiber net as material, use warp knitting machine to weave core layer reinforcement, impregnate and coat with polytetrafluoroethylene dispersion emulsion, make 20 feet cabinet The main part of the blue container.

[0078] Specific steps are as follows:

[0079] (1) Choose 300g / m 2 90° yarn layer 7 on the lowest layer of carbon fiber chopped fiber mesh, 200g / m2 carbon fiber prepreg is laid on 90° yarn layer 8, 9 and 0° yarn layer 11, and 1500dtex high temperature filter bags are used to recycle recycled fiber spinning The finished yarn (mainly composed of polyimide, aramid fiber, polytetrafluoroethylene fiber) spreads +45 ° and -45 ° yarn layers 10, 12, selects 500dtex nylon filament as binding yarn 13, and above-mentioned 6 layers of yarn The wire layers are bundled into a core reinforcement.

[0080] The speed of the knitting machine is 2m / min. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com