Preparation method of end-capped modified perfluoroalkyl polyether

A technology of perfluoroalkyl polyether and perfluoroalkyl, which is applied in the field of preparation of end-capped modified perfluoroalkyl polyether, which can solve the problems of low foam, surface tension, and inability to synthesize addition numbers, etc., and achieve low foam High performance, excellent application performance, and the effect of less by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

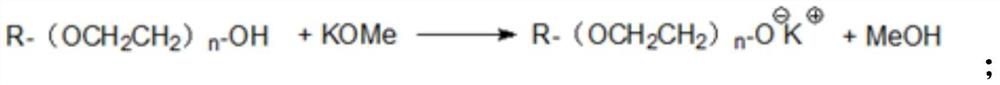

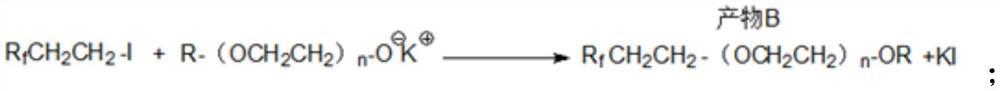

Method used

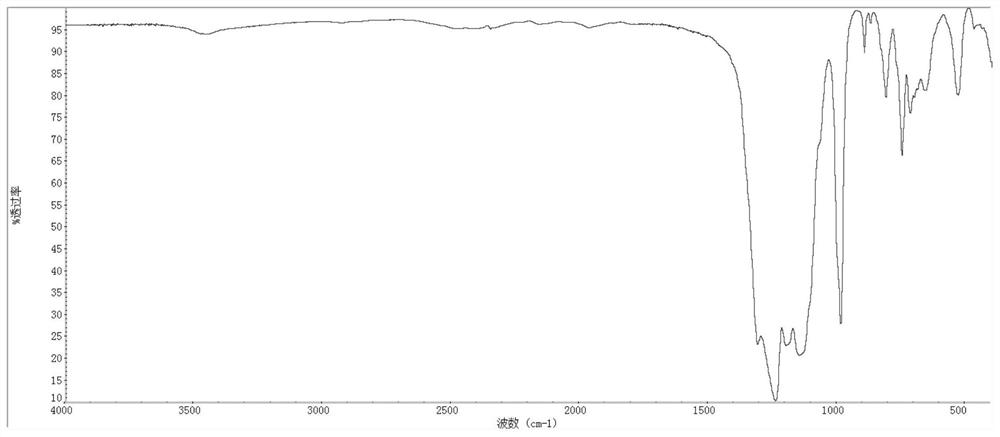

Image

Examples

Embodiment 1

[0025] Add 0.1 mol methoxypolyoxyethylene ether (MPEG-2000) and 0.1 mol potassium methylate to a 1 L stirred tank, check the air tightness of the reactor, replace the nitrogen for 3 times and pressurize to 300KPa, and wait for the reactor to After no pressure drop occurs within 1 hour, the temperature is raised to 100°C to 50°C, vacuumed to ≤-99.0KPa or above, and the alkoxide is maintained for 5 hours, and then perfluorooctyl iodide is slowly added dropwise for 2 hours. After the dropwise addition, use 5% phosphoric acid to adjust the pH to 5.0-5.5, dehydrate and filter to get the clear liquid to remove the salt. The appearance of the product is reddish, and the surface tension of 0.1% is 30.4 dyn / cm. The cloud point is 71.7°C (5% sodium chloride aqueous solution).

Embodiment 2

[0027] Add 0.1 mol methoxypolyoxyethylene ether (MPEG-2000) and 0.1 mol potassium methylate to a 1 L stirred tank, check the air tightness of the reactor, replace the nitrogen for 3 times and pressurize to 300KPa, and wait for the reactor to After there is no pressure drop within 1 hour, the temperature is raised to 100°C, vacuumed to ≤ -99.0KPa, and the product is kept in alkoxide for 5 hours, then slowly added perfluorooctyl iodide to the product, the drop time is 1 hour, dropwise The time is 2 hours. After the dropwise addition, adjust the pH with 5% phosphoric acid, dehydrate and filter to remove salt. The product has a light yellow appearance and a 0.1% surface tension of 25.6 dyn / cm. The cloud point is 75.8°C (5% sodium chloride aqueous solution).

Embodiment 3

[0029] Add 0.1 mol methoxypolyoxyethylene ether (MPEG-2000) and 0.1 mol sodium methoxide into a 1 L stirred tank, and check the airtightness of the reactor, and wait for no pressure drop in the reactor within 1 hour Raise the temperature to 100°C, evacuate to ≤-99.0KPa or above, keep the alkoxide for 5 hours, then slowly add perfluorooctyl iodide to the product, and the addition time is 2 hours. After the dropwise addition, adjust the pH with 5% phosphoric acid, dehydrate and filter to remove salt. The product has a pale yellow appearance and a 0.1% surface tension of 32.8 dyn / cm. The cloud point is 68.4°C (5% sodium chloride aqueous solution)

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cloud point | aaaaa | aaaaa |

| Surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com